Abstract

As opposed to open surgery procedures, minimally invasive surgery (MIS) utilizes small skin incisions to insert a camera and surgical instruments. MIS has numerous advantages such as reduced postoperative pain, shorter hospital stay, faster recovery time, and reduced learning curve for surgical trainees. MIS comprises surgical approaches, including laparoscopic surgery, endoscopic surgery, and robotic-assisted surgery. Despite the advantages that MIS provides to patients and surgeons, it remains limited by the lost sense of touch due to the indirect contact with tissues under operation, especially in robotic-assisted surgery. Surgeons, without haptic feedback, could unintentionally apply excessive forces that may cause tissue damage. Therefore, incorporating tactile sensation into MIS tools has become an interesting research topic. Designing, fabricating, and integrating force sensors onto different locations on the surgical tools are currently under development by several companies and research groups. In this context, electrical force sensing modality, including piezoelectric, resistive, and capacitive sensors, is the most conventionally considered approach to measure the grasping force, manipulation force, torque, and tissue compliance. For instance, piezoelectric sensors exhibit high sensitivity and accuracy, but the drawbacks of thermal sensitivity and the inability to detect static loads constrain their adoption in MIS tools. Optical-based tactile sensing is another conventional approach that facilitates electrically passive force sensing compatible with magnetic resonance imaging. Estimations of applied loadings are calculated from the induced changes in the intensity, wavelength, or phase of light transmitted through optical fibers. Nonetheless, new emerging technologies are also evoking a high potential of contributions to the field of smart surgical tools. The recent development of flexible, highly sensitive tactile microfluidic-based sensors has become an emerging field in tactile sensing, which contributed to wearable electronics and smart-skin applications. Another emerging technology is imaging-based tactile sensing that achieved superior multi-axial force measurements by implementing image sensors with high pixel densities and frame rates to track visual changes on a sensing surface. This article aims to review the literature on MIS tactile sensing technologies in terms of working principles, design requirements, and specifications. Moreover, this work highlights and discusses the promising potential of a few emerging technologies towards establishing low-cost, high-performance MIS force sensing.

Keywords: MEMS, sensors, surgery, laparoscopic, minimally invasive surgeries, robotic, tactile

1 Introduction

Minimally invasive surgery (MIS) has changed surgical practices during the last three decades, and it has attracted the attention of many researchers who are trying to contribute to its development. MIS procedures are achieved through small incisions (0.3–1 cm) or natural orifices such as the mouth, nose, urethra, vagina, and anus. MIS instruments are characterized by small size, flexibility, precision, and reliability (Hindle and Hindle, 2001; Kelley, 2008).

MIS includes numerous advantages such as reduced postoperative pain, shorter hospital stay, decreased surgical site infections, and faster recovery time. MIS approaches have now become the gold standard of several common procedures in our daily practice, including appendectomy, cholecystectomy, and hernia repairs (Litynski, 1999). Such revolutionary advances would not have been made possible without the development of improved instruments, anesthesia, and advanced optical methods (Lane, 2018). In an attempt to improve current techniques and technologies, the concept of minimally invasive robotic surgery (MIRS) was introduced, where surgeons operate medical robots to perform MIS procedures. The MIRS offers increased dexterity to surgeons who wish to perform complex cases, even in reduced anatomical spaces, with greater precision and accuracy. Undesirable, yet inevitable, vibrations and tremors that would usually come from the surgeon’s hands in MIS are also eliminated altogether (Fuchs, 2002). Today, it remains the most popular method used to detect cancer through a procedure called palpation, in which surgeons indirectly feel tissues in an attempt to determine the presence of harder, stiffer tumor cells (Krouskop et al., 1998).

The recent advancements in robotics and control systems are pushing MIS one step further. As an example, the da Vinci robotic surgical system, shown in Figures 1A,B, was launched in the late 90s and is currently being used around the world in various surgeries, offering 3D immersive vision, motion scaling, and simplification of otherwise complex movements (Ballantyne and Moll, 2003; Palep, 2009). Further developments in MIRS and telecommunications are also making telesurgery possible, in which surgeons can perform computer-driven surgeries remotely from different locations (Marescaux et al., 2001; Alderson, 2019). On the other hand, the implementation of the MIRS has encountered several limitations mainly associated with the high costs of operations. The initial investment is very high, usually ranging from $1 million to $2.5 million, shooting up the overall operational cost per case to $3,200 on average (Morgan et al., 2005; Turchetti et al., 2012). Eventually, an average of 150–250 procedures must be performed in order for a surgeon to become proficient in operating the robot (Barbash and Glied, 2010).

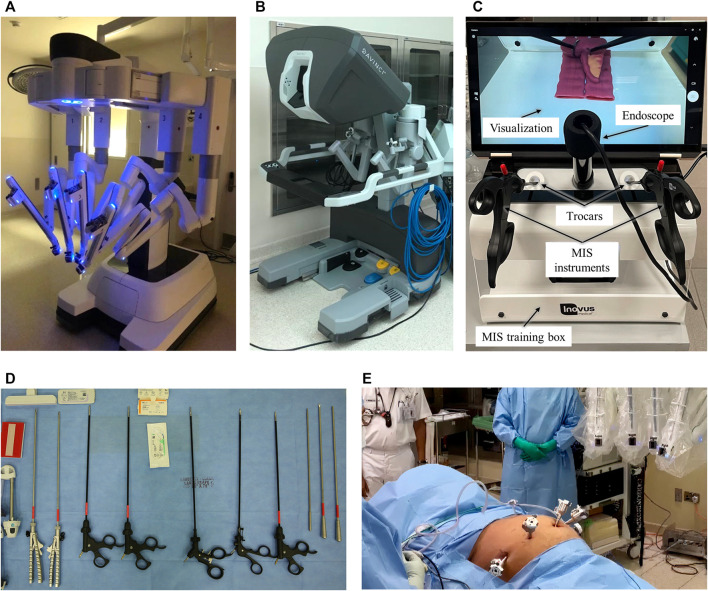

FIGURE 1.

Minimally Invasive Surgery Systems. (A,B) Da Vinci surgical robotic system for MIS: (A) patient cart holding the camera and instruments that the surgeon controls remotely and (B) surgeon console that controls the instrumented arms and provides a high-definition 3D view of the operation site. (C) Laparoscopic box trainer with an endoscope and surgical instruments used for MIS simulations. (D) Surgical instruments used in laparoscopic surgery and training. (E) Laparoscopic operation with port accesses in the abdominal cavity and the docking of the robot arm with the ports.

From the medical perspective, the lack of sense of touch when using MIRS is a major challenge. Historically, open surgery allowed surgeons to have direct contact with the tissue and preserve the touch sense. With the introduction of laparoscopic surgery (LS), this sense was partially affected but completely eliminated with MIRS. The commonly used robotic surgical systems, such as the da Vinci system, has no touch feedback; nonetheless, the sense of touch is essential for safely maneuvering organs, tissues, and sutures. Haptic, or touch-based, interactions offer more reliable determination of the consistency of the tissues, preventing surgeons from accidentally applying excessive forces and damaging them (Sastry et al., 1997). Additionally, grasping force feedback helps to prevent tissue slippage, hence enhancing MIS time efficiency. Therefore, a critical necessity is to develop sensorized MIS tools that bio-mimic the human finger’s ability to detect normal and shear forces, tissues’ softness, and other physical properties. Furthermore, MIS simulations, such as the one shown in Figure 1C, become more effective for trainees when combined with force feedback systems. Training with sensorized instruments provides awareness of the forces being applied and the tissues being grasped, leading to a shorter learning curve with a steadier upward trend (Overtoom et al., 2019).

The two essential components to bring the sense of touch back into MIS include tactile force sensing of the instruments and haptic feedback to the surgeon. In this review, we will solely focus on discussing the different types of sensors used in tactile force sensing and their respective recent developments within MIS. In the literature, several interesting reviews targeted the general biomedical applications while touching on the MIS and RMIS fields (Tiwana et al., 2012; Al-Handarish et al., 2020). Some other reviews focused more on MIS conventional tactile sensing technologies (Eltaib and Hewit, 2003; Konstantinova et al., 2014; Bandari et al., 2020). Further, a recent review paper on tactile perception in MIS is focused on the algorithms utilized by the tactile sensing systems to evaluate the data rather than discussing the sensing principles of sensors (Huang et al., 2020). To this end, this work is an up-to-date comprehensive review, attacking from a historical progress point of view, discussing conventional methods in a balanced manner, comparing the pros and cons of all methods, and highlighting emerging technologies that could potentially contribute heavily to the MIS tactile sensing field.

The history of MIS and the requirements for implementing tactile sensors with surgical tools are highlighted in Sections 2 and 3, respectively. Following this, MIS-oriented studies concerning two conventional tactile sensing approaches, i.e., electrical and optical sensing, are discussed in Section 4. In Section 5, the potential of emerging tactile sensors, i.e., microfluidic and imaging sensors, as promising candidates for developing sensorized MIS tools is presented. Towards the end, current technological obstacles and perspective outlooks are summarized in the concluding remarks.

2 Minimally Invasive Surgery

“Surgeons applaud large incisions and denigrate “keyhole surgery.” Patients, in contrast, want the smallest wound possible, and we at Britain’s first department of minimally invasive surgery are convinced that patients are right,” John Wickham, who first coined the term minimally invasive surgery (MIS), wrote in an article in British Journal of Surgery published in 1987 (Hindle and Hindle, 2001).

Over the past five decades, the evolution of the surgical field has exceeded the expectations in terms of clinical outcomes, from large incision/open procedures in the 1950s to MIS in the late 1990s, followed by the revolution of the MIRS in the late 2000s. As a result of the availability of advanced technologies and new surgical tools in the market, the development of novel surgical approaches has been the target of different surgical groups worldwide. As mentioned above, MIS’s concept encompasses all the diagnostic and/or therapeutic techniques accessing different anatomical cavities, organs, and tissues through natural orifices or small incisions (Kelley, 2008), for example, the access of the abdominal cavity in order to remove the gallbladder (laparoscopy), the access of the chest for a lung nodule removal (thoracoscopy), the access to the knee for a ligament repair (arthroscopy), and the access to the colon in order to remove a polyp (colonoscopy). The commonly used surgical instruments in laparoscopic surgery and training are shown in Figure 1D.

The approach has many advantages, such as less postoperative pain, fewer surgical incisions, shorter hospital stay, better postoperative recovery time, and lower risk of surgical site infections (Hindle and Hindle, 2001; Kelley, 2008). Its use has not been limited to the field of general surgery, whereas urologists, gynecologists, cardiovascular surgeons, thoracic surgeons, vascular surgeons, and other specialties have also taken advantage of the evolution of these surgical systems.

The earliest record of endoscopy, or the practice of introducing instruments into the body to view internal organs, was introduced by Hippocrates (460–370BC), the “Father of Medicine.” Modern endoscopy only began with the advent of light conductors used to illuminate body parts (1853), as well as tubes used to extract fluids and ascites from the body (1938) (Radojcić et al., 2009). However, the profound development of these minimally invasive techniques started in the early 1970s when Shinya and Wolfe reported the first experiences of removing colon polyps using rigid colonoscopes, procedures characterized by minimal morbidity and mortality. These were the formal beginnings of a new era called “endoscopic surgery.” With time, this practice became solidly and routinely established by numerous gastrointestinal surgeons. Posteriorly, the LS was consolidated in the late 1980s with the incorporation of video laparoscopy, a technology developed since the 1960s by various groups of gynecologists and urologists in Germany. Its most prominent and remembered leader was Kurt Semm. The first case of LS successfully reported in the medical literature was in 1987 by the French surgeon Phillip Mouret. The procedure performed was a laparoscopic cholecystectomy. Two years later, in 1989, the American College of Surgeons (ACS) endorsed this new surgical procedure with the support of other leaders in the surgical field, Eddie Reddick and Douglas Olsen (Kelley, 2008).

Almost two decades ago, using the same principles, the concept of endoscopic surgery through natural orifices was established by its acronym “NOTES.” A considerable number of surgeries were developed using a combination of endoscopic and laparoscopic instruments, with the aim of accessing the abdominal cavity and removing organs without external scars. Its most important leaders were Kalloo and Kantsevoy. These concepts became relevant when they were scientifically accepted by the American Society of Gastrointestinal and Endoscopic Surgeons (SAGES) and the American Society of Gastrointestinal Endoscopists (ASGE). Then, several other procedures were developed: transoral appendectomy, transvaginal cholecystectomy, transvaginal nephrectomy, and transvaginal gastric sleeve. Although the difficulties in standardizing the techniques limited their popularity at the time, they still played a significant role in the evolution of MIS (Litynski, 1999).

More recently, MIRS emerged with the aim of offering various advantages over traditional LS, such as three-dimensional vision, greater dexterity, improved mobility, usage of articulated instruments, increased range of movements, reduced tremor, and better ergonomic position for the surgeon (Lane, 2018). Figure 1E shows a robot-assisted laparoscopic operation with port accesses in the abdominal cavity and the robot arms docking with the ports. MIRS history began with the Puma 560 robot, used by Kwoh to perform neurosurgical biopsies with greater precision in 1988 (Lanfranco et al., 2004). For gastrointestinal surgery, the big step was taken in 2001 when Marescaux performed the first transcontinental robotic cholecystectomy, where the surgeon was based in New York (United States) using the ZEUS surgical system and the patient was on the operating room table in Strasbourg (France) (Marescaux et al., 2002). Subsequently, the da Vinci surgical system was positioned as the most complete and developed robotic platform with the endorsement of the Federal Agency for the Administration of Food and Drug Administration (FDA) in 2000. The future of the MIS will be influenced by several factors, including the development of new surgical instruments with better performance. The field of research is advancing by leaps and bounds in order to provide the patient with the best possible clinical outcomes (Alderson, 2019).

3 Tactile Sensing in Minimally Invasive Surgery

In the modern era, the increased interaction between humans and technological devices has motivated the development of several sensing devices, e.g., temperature (Moser and Gijs, 2007), humidity (Han et al., 2012), accelerometers (James et al., 2004), and gas sensors (Tit et al., 2018; Shaheen et al., 2020). Recently, tactile sensing has gained significant interest due to its potential impact on MIS grasping and manipulation, among other applications. Ever since MIS has become mainstream within the medical community, many proofs of concept and sensor-integrated instruments have been attempted and tested. Despite the hundreds of studies and research efforts to integrate tactile sensation and haptic information in MIS, to this day, no commercialized product has been established in the mainstream. However, this is not to say that significant progress has not been made to put the sense of touch back into the hands of surgeons. By looking into the history of MIS, it is evident that tactile sensing has been a challenging task, and recently its developments have dramatically escalated.

As stated earlier, the first LS through a minimal incision dates back to the 1970s. This was about the time when tactile sensing for applications in robotics first emerged, intending to allow machines to receive and respond to force input (Tegin and Wikander, 2005). In the same year that video laparoscopy was introduced (1982), one of the first robotic-application tactile sensing reviews was published by Harmon, highlighting present and future outlooks of tactile sensing and its potential in the field. Harmon singled out three tactile sensing fields that require major development across all criteria: prosthetics, medical examination, and surgery, all of which are medical applications (Harmon listed industry, space, underwater, assembly, and other applications as less difficult and better developed) (Harmon, 1982). He also noted that those three fields are in high demand for decent spatial and time resolution, force sensitivity, range, and complex pattern recognition, giving the applications a 5 out of 5 on the “demanding scale.” It is made clear that starting from the 1980s, tactile sensing for medical applications was a field in need of development.

Advanced robotic grippers with integrated force and torque sensors, laser range detectors, actuators, and communication electronics emerged during the 1980s (Dietrich et al., 1990). Although Harmon’s desire for automation in MIS was never realized, several developments were made in manufacturing tactile sensor arrays, miniaturization, and new designs specifically targeted towards detecting tissue properties during the 1990s and 2000s. Several studies were performed to prove the advancements and potential for robotic grippers in MIS. For instance, Trejos et al. (2008) showed that robot-conducted palpation led to a 35% decrease in maximum applied force and a 50% increase in detection accuracy of tumors, as well as an improved completion time.

In 1999, the World Health Organization established a new protocol regarding proper cleaning and sterilization of medical instruments with the possibility of being subjected to prion contamination (World Health Organization, 2000). This guideline mandates tools to be sterilized with sodium hydroxide or sodium hypochlorite—both corrosive chemicals pose a threat to the involved electronics and circuits (Trejos et al., 2008). The new requirement sets a new standard for all MIS sensors and will ensure that any MIS-ready tactile sensing device must withstand sterilization. It is worth noting that these issues that once hindered the development of tactile sensing in MIS remain obstacles. Miniaturization while preserving sensitivity and range and resistance to flexing and sterilization and being easily manufactured and disposable are still issues and trade-offs that affect modern designs. While many researchers have designed elaborate systems that help with tasks such as ranking stiffness, discriminating organs, and determining tissue properties, such as the feedback endoscopic surgical grasper developed by Rosen et al. (1999), few have demonstrated technology that is affordable and easily usable. Just as important as functionality, making a force and tissue sensor universally affordable and easily usable without specialized training is key to a successful design.

Over recent years, more attention has been given to processing force data and presenting the feedback to surgeons. While many have traditionally used visual displays to warn of tissue irregularities detected by laparoscopic devices, others have experimented with vibrational, auditory, or temperature cues. For example, Yao (2004) investigated using an arthroscopy hook with an accelerometer that amplified forces and vibrations through an actuator on the handle. When coupled with auditory feedback, tear detection was improved in an experiment. Other methods, such as tactile displays, have also been explored but with little success. In another demonstration by King et al. (2009a), the addition of a tactile feedback system has substantially decreased the grip force when performing the same task. This has implications in preventing damage made to grasped tissues and improving the overall control and maneuverability of devices. Documentation has proven that the combined effort in developing tactile sensing and feedback is important for providing haptic guides to surgeons.

Typical tactile sensors, regardless of their transduction technology, consist of three major components. The first is the sensing unit that converts pressure to a quantifiable signal. Common transducer technologies used in MIS include piezoresistive, piezoelectric, capacitive, optical, and elastomeric technologies (Bandari et al., 2020). Depending on the application, individual sensing elements can be arranged into one- or two-dimensional arrays, distributed across a continuous plane. For instance, palpation requires the measurement of relative hardness variations across a tissue, requiring a two-dimensional cluster of individual sensing elements (Naidu et al., 2016). Then comes an electronics component that contains specific circuits to process, filter, and interpret data (Eltaib and Hewit, 2003). The final component offers either rigid or flexible supports and protection, including waterproofing, heatproofing, and shock-proofing elements. However, it is crucial that this layer does not interfere with the operation of the sensing elements, produce excessive noise and inaccuracies, or cause a significant change in the stiffness of the structure.

The current structure of MIS tools has guided the development of MIS force sensing systems. Several researchers have evaluated the integration of force sensors at different locations on MIS graspers and probes. Few attempts proposed having the sensors outside the patient’s body to simplify the measurement of forces, as the size and sterilization requirements are not involved (Hanna et al., 2008). In some other attempts, installing sensors on the shaft of the tool allowed for measuring kinesthetic forces acting at the tip of the instrument (Berkelman et al., 2003). As an advantage of such indirect force measurements, contact forces are acquired without compromising the contact surface of the tool. However, the accuracy and precision of the indirect measurement remain questionable due to the influence of friction at the entry point and driving mechanism (Shimachi et al., 2004). Also, forces acting on the tissue are not exactly represented by forces acting on the handle of the instrument (Trejos et al., 2008). On the other hand, the direct measurement technique of contact forces at the tissue-tool level has been proven more precise and accurate (Özin et al., 2019). Sensors placed on the grasping tips are capable of accurately measuring kinesthetic and tactile forces in real-time. The contact area and pressure distribution, as well as the pressure center, can only be measured directly. Furthermore, the direct force measuring technique is not affected by the friction of the driving mechanism and is solely dependent on the interaction at the end-effector of the tool. Nevertheless, the addition of a tactile sensor, e.g., a thin-film layer, between the instrument and the tissue alters the tool characteristics by a certain amount. The debate on what location is the most suitable for MIS force sensors integration is still active, where a combination of different sensing locations might bring up more conclusive force measurements in a trade-off with the overall cost of the sensorized surgical instrument.

Different types of forces are involved when considering tactile sensing for MIS. Information about forces, whether being measured at the tip, the rod, or the base of the tool, can be used to restore the grasping, manipulation, and displacement actions performed by the surgeon. The most important and straightforward type of force to measure is the normal force that can provide an estimation of the applied pressure on the grasped or palpated tissue. Measuring static normal forces can prevent tissue damage from an overwhelmed grasping and manipulation (Tholey et al., 2004). On the other hand, meaningful information about tissue biomechanics, e.g., stiffness, can be obtained through dynamic loading. With the aid of MIS techniques, the detection of tumorous regions within the tissue is achieved through dynamic palpation (Krouskop et al., 1998). The shear force, also referred to as friction force, occurred to be important in preventing tissue slippage from the tool and maintaining the tissue in the safe zone without damage (Khadem et al., 2016). It was validated that, through estimating shear forces, sensorized MIS tools can provide both stability and robustness to the grasping action and improve the efficiency of the operation. Normal and shear force can also be measured on the different spots of the tool to detect any kind of undesired pressing or friction with nearby organs. In situations where blood vessels are present, they can be avoided by sensing the weak periodic pressures caused by pulses.

Before discussing each respective tactile sensing method, it is worth examining the sensor requirements associated with tactile sensing in MIS. The list of requirements, presented in Table 1, acts as criteria determining how appropriate and effective the sensor is within MIS procedures.

TABLE 1.

List of sensor requirements for MIS tactile sensing.

| Category | Requirement | Description |

|---|---|---|

| Operational requirements | Sensitivity | Produce accurate data with at least 0.2 N sensitivity for MIS (Lazeroms et al., 1996) |

| Dynamic range | Typical medical forces range between ±10 N, laparoscopic surgical tools apply forces between 0 and 25 N but can go as high as 40 N (Kalantari et al., 2010) | |

| Frequency | Typical laparoscopic grasping frequencies do not exceed 3 Hz (Sarmah and Gulhane, 2010) | |

| Repeatability/linearity | Produce repeatable, precise data without drift and hysteresis error in differing environments | |

| Dexterity | Cannot sacrifice or interfere with surgeon dexterity (by being too bulky, fragile, rigid) | |

| Response rate | Provide rapid, on-the-fly measurements (within 1 millisecond) (Yousef et al., 2011) | |

| Hardware requirements | Miniaturization | Needs to fit within laparoscopic width of 5–8 mm in a typical MIS tool |

| Reliability | Robust, functional through entire surgical operation, reducing moving parts in sensor usually increases reliability | |

| Waterproofing | Needs to be resistant in bodily environments of bodily fluids, organs, and soft tissues | |

| Compatible with MIS tools | Cannot interfere and be interfered with the operation of endoscopes, catheters etc. | |

| Sterilizable | Needs to be easily sterilizable for MIS to avoid contamination of infection (needs to be stable in acidic and basic sterilizing environments) | |

| External requirements | Cost | Laparoscopic tools are thrown out after each operation, so they need to be disposable and affordable |

| Assembly | Needs to be easily assembled and integrated within a wide range of MIS models and tools, will also become beneficial for mass production purposes | |

| Recommended requirements | Working area | Wide working area to allow force measurement across a laparoscopic grasper or tool |

| Compliance measurements | Measurement of hardness and softness of tissues through the force sensor | |

| Force identification | Differentiation between normal and shear forces helps with tissue characterization, surface friction, viscosity (Yousef et al., 2011) | |

| Temporal variation | Differentiate between dynamic and static forces, measure both accurately (Yousef et al., 2011) |

4 Conventional Tactile Sensing Technologies

Tactile sensors for MIS and MIRS applications should be capable of estimating the magnitude, direction, and location of the applied force on the contact surface. Additionally, evaluating the compliance and texture of the grasped organs and detecting slippage are fundamental requirements for increasing the efficiency of the medical practice. In order to facilitate these capabilities, several studies attempted to integrate tactile sensors that bio-mimic the human tactile system with MIS surgical instruments. This section discusses the conventional tactile sensors designated for MIS, which are mainly silicon-based devices fabricated using the micro-electro-mechanical systems (MEMS) technology, and developed based on electrical or optical tactile sensing principles.

4.1 Piezoresistive Tactile Sensing

Piezoresistive force sensors rely on the piezoresistive effect, wherein applied mechanical forces lead to measurable changes in the electrical resistance of the sensing element (Tiwana et al., 2012). This type of force sensor utilizes a piezoresistive component, usually a metal, conductive elastomer, or semiconductor such as a silicone substrate, which deforms or distorts in structure under the application of pressure (Yousef et al., 2011). Such deformations can either increase or decrease the electrical resistance of the sensing material according to its geometry and orientation. The value of the resistance, , is given by the following:

where is the resistivity, is the length, and is the cross-sectional area of the element. The change in resistance due to applied stress is a function of geometric and resistivity changes, which is given by the following (Johns, 2006):

where is Poisson’s ratio. In metallic conductors, i.e., strain gauges, the change in resistance is mainly a function of the physical dimensions and geometric effects, . In semiconductors, however, the change in the bulk resistivity, , gives even a more significant contribution to the change of resistance.

Two electrodes connected to the piezoresistive element’s ends allow this change in resistance to be measured. Under loading, the induced change in the sensor's resistance can be measured by applying a constant voltage, V, and monitoring the change in the electrical current, I, or vice versa, according to the equation: ΔR = Vconst/ΔI or ΔR = ΔV/Iconst. The measured electrical change can indicate the extent to which resistance has been altered (Tiwana et al., 2012). The correlation between applied force and measured resistance (usually found to be linear) can then be calculated and implemented, usually into biomedical or automotive applications (Samaun et al., 1971; Ruhanen et al., 2008).

There are several benefits associated with piezoresistive force sensors. Due to its maturity in the market, serving as one of the most popular tactile sensing technologies in the mechanical and robotic industry, it has been widely improved and developed since its inception (Stassi et al., 2014). This has made the sensor sufficiently simple and of low cost to produce, along with improvements in making for a relatively low-power-consuming sensor (Stassi et al., 2014). Piezoresistive sensors, with their flexible physical qualities, have also been known to be less susceptible to noise and less vulnerable to shock, vibration, and temperature (Tiwana et al., 2012). High sensitivity, repeatability, and spatial resolution are also qualities that make the sensor ideal for several applications (Samaun et al., 1971). The ability to shape, flex, stretch, and scale these sensors onto gloves and skin for medical purposes also makes such a technology versatile (Sorab et al., 1988; Papakostas et al., 2002; Latessa et al., 2009; Büscher et al., 2015). Geometric scaling is known to be significantly easier compared to its counterparts (Weinstein and Bhave, 2008). Moreover, piezoresistive sensors have been used in many different biomedical applications such as intracranial pressure monitoring (Lalkov and Qasaimeh, 2017), catheters (Meena et al., 2017), and personal healthcare (Trung and Lee, 2016).

On the other hand, drawbacks include the trade-off of flexibility and sensitivity upon miniaturization (Yousef et al., 2011). For example, a decrease in piezoresistive layer thickness corresponds to an increase in both sensitivity and noise (Wang et al., 2005). The stiffness and fragility have been overcome by embedding piezoresistive sensors with flexible polymers (such as polyimides), making their conformation onto surfaces easier (Yousef et al., 2011). Piezoresistive sensors are also prone to hysteresis, an error inflicted as a result of the continuous bending or pressuring of the piezoresistive material, which may lead to retardation or temporary inaccuracies in measurement. Chuan and Chen (2011) demonstrated that hysteresis of silicon piezoresistive sensors, for instance, can be compensated through utilizing an inverse general Preisach model. The wiping-out property was found to be effective in compensating for hysteresis error and therefore proved to be a suitable solution to this piezoresistive limitation.

The most common method of integration of piezoresistive sensors for MIS is through a laparoscopic grasper. Basically, piezoresistive sensors can be mounted onto the interior surface of the jaws, where grasping force and pressure data are obtained and sent to systems to provide feedback to surgeons. Whereas the form in which feedback is provided can vary from visual and auditory to heat and vibration, this section will discuss the use of piezoresistive sensors within MIS and the conclusions such studies have garnered.

Such a proof of concept that demonstrates the suitability of piezoresistive sensors within laparoscopic graspers in robotic surgery was presented by Sarmah and Gulhane (2010). Commercially available piezoresistive force sensors were purchased from Tekscan, providing researchers with a thin-profile (208 µm), miniature (10 mm diameter), and flexible FlexiForce piezoresistive sensor. These off-the-shelf sensors were chosen for their static and dynamic performance, high linearity, and force range (0–110 N), meeting the force range standards for palpation and other laparoscopic functions as described earlier. Electrodes were composed of silver conductive strips, and researchers used inverting amplification circuits to measure force through measured changes in resistance. When coupled with a strain-gauge sensor, the sideways manipulation force was also detected, allowing test surgeons to grasp tissue through the robotic arm and simultaneously feel varying grasping pressure levels through the robotic controls. Similarly, King et al. (2009b) took this concept of directly integrating commercially available sensors into laparoscopic tools one step further, developing a functional da Vinci robotic surgical system with tactile features. By integrating the piezoresistive substrates onto the system’s cadière grasper tool, along with a multielement tactile feedback (MTF) system, they were able to prove the feasibility of the feat into commercial surgical systems. Perceptual tests with human participants showed the static and dynamic force accuracy of such an application.

One of the most lauded qualities of the piezoresistive sensor is the flexibility to design a sensor to fit the specific dimensions, resolution, and ranges of the sensor to serve a researcher’s purpose. Such a challenge to design, fabricate, and evaluate a piezoresistive hardness sensor for MIS was explored by Kalantari et al. (2010). Piezoresistive sensors were chosen for their quick response time, low noise in results, and ease of microfabrication. As shown in Figure 2A, the final design consisted of two piezoresistive sensors, a large (15 mm diameter) sensor capped with a ring-shaped filler plate of similar dimensions and a small (6 mm diameter) sensor embedded within the empty interior hole of the filler plate. Forces applied on the filler plate are first recorded on the large sensor. When the examined material is displaced enough to come in contact with the smaller sensor within the filler plate, the force is recorded again on the large sensor. This means that, relative to harder materials, softer materials come in contact with the smaller sensor through less applied force, implying that they are more flexible and bendable. Therefore, such a design allows the determination of a material’s resistivity for bending within the filler plate, and thus, its hardness.

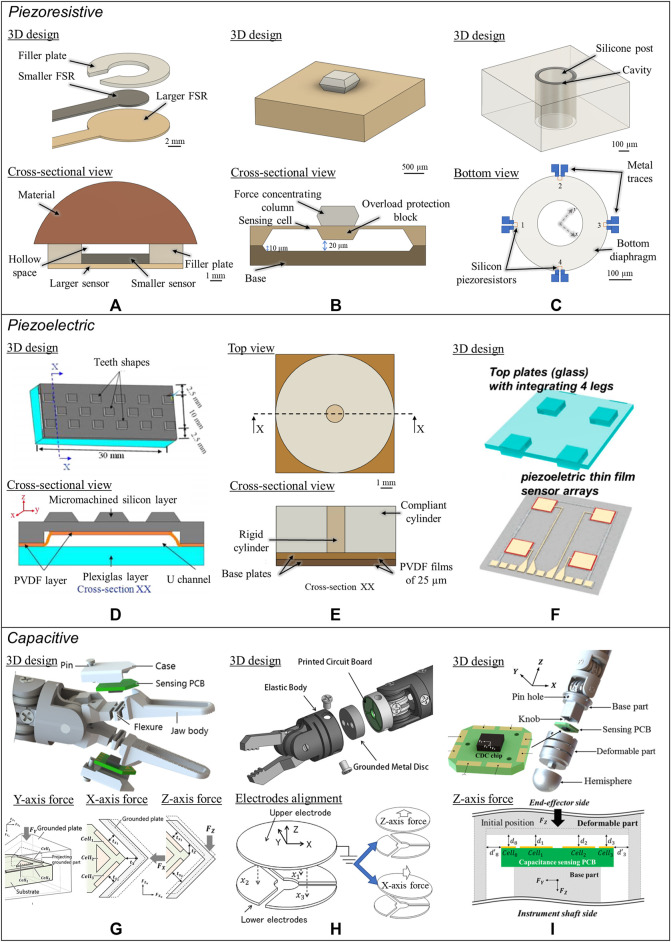

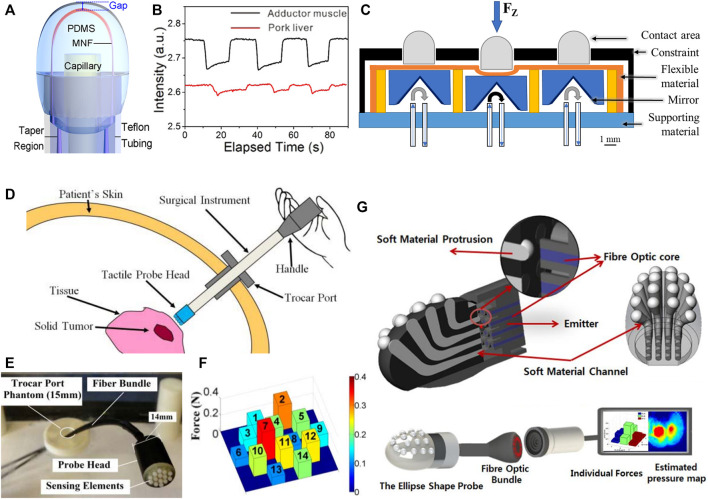

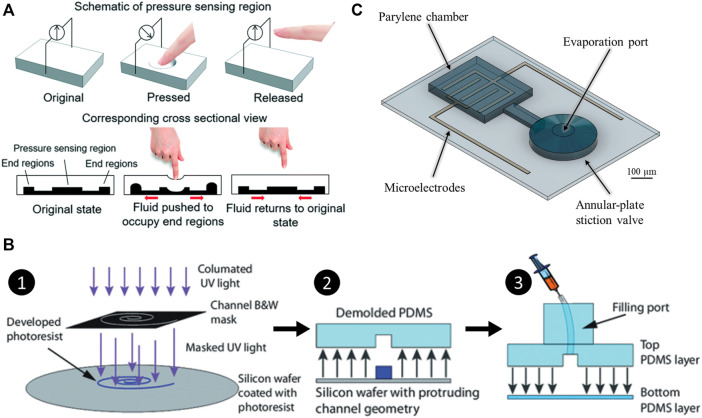

FIGURE 2.

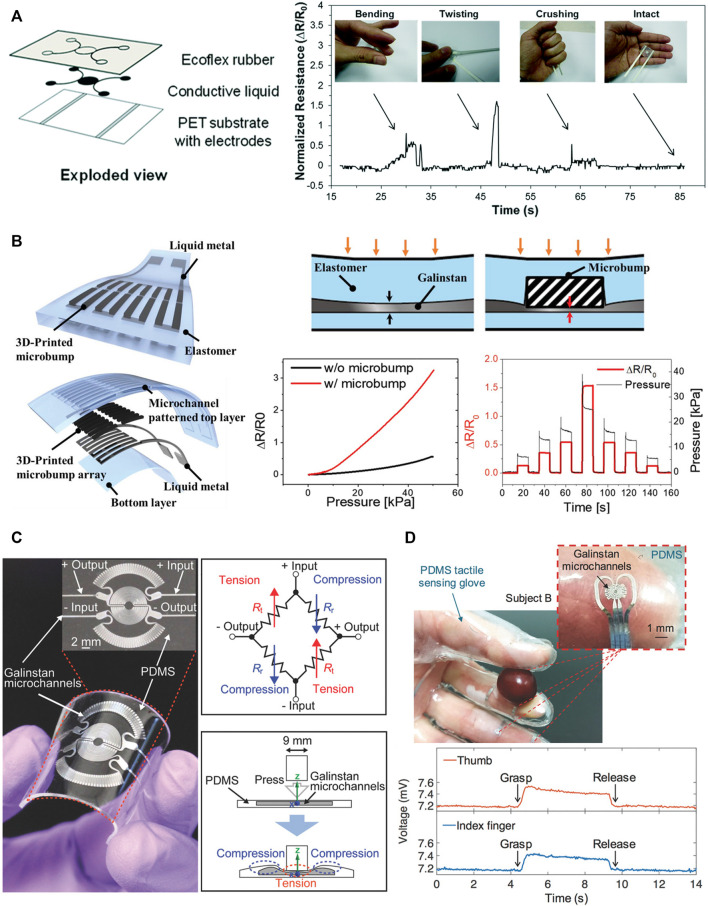

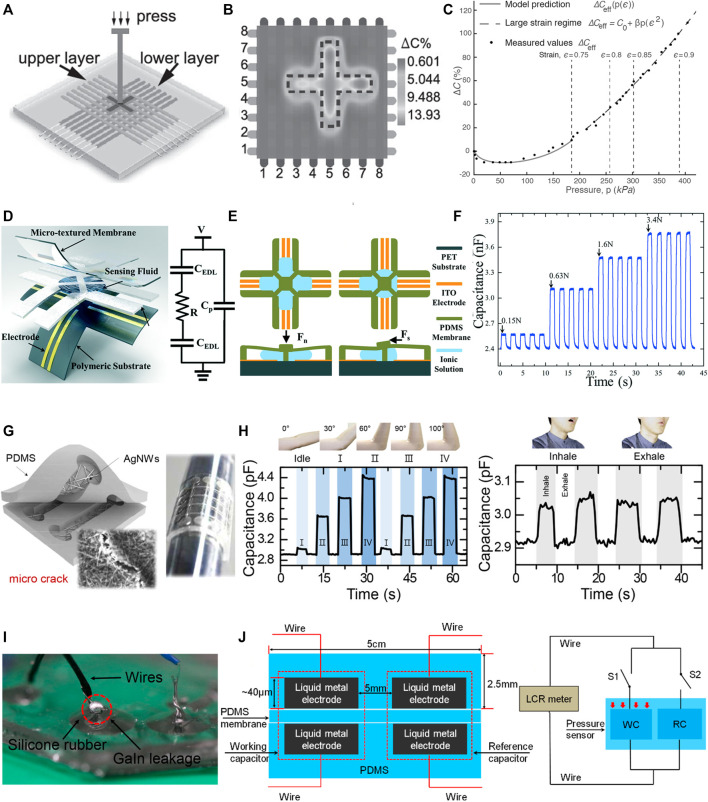

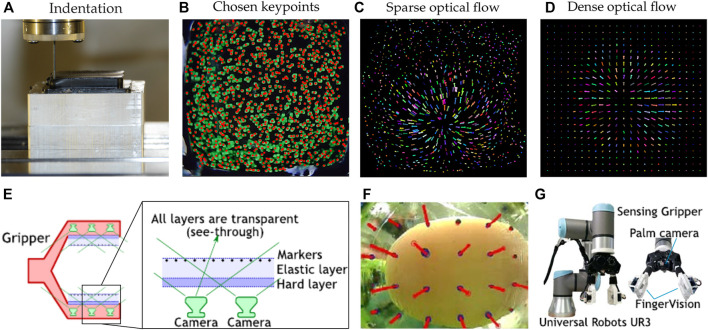

Electrical-based tactile sensors for MIS. (A–C) Piezoresistive tactile sensing. (A) Schematic and cross-sectional view of the piezoelectric tactile sensor consisting of two circular force sensing resistors with different diameters and one plastic filler plate, which can differentiate between the hardness of other types of elastomers (Kalantari et al., 2010). (B) Illustration of mechanical structure and a cross-sectional view for the individual three-dimensional force sensing cell of the tactile sensor (Mei et al., 2000). (C) 3D illustration and backside view of the bioinspired piezoelectric tactile sensor consisting of a silicone post on top of a bottom diaphragm with strain gauges (Hu et al., 2010). (D–F) Piezoelectric tactile sensing. (D) Schematic showing the structure and cross-sectional view of PVDF-based piezoelectric tactile sensor composed of three layers: a double-sided micromachined silicon plate, a PVDF film, and a Plexiglas support layer (Qasaimeh et al., 2008a). © 2008 IEEE. Reprinted, with permission. (E) The structural design of a PVDF-based sensor consisting of a rigid cylinder surrounded by a compliant cylinder for compliance measurement (Sedaghati et al., 2005). (F) Illustration of the triaxial tactile sensor employing an array of four active piezoelectric sensors (Lee et al., 2014). Copyright (2019) MDPI. (G–I) Capacitive tactile sensing. (G) Exploded view of the sensorized surgical forceps and the configuration of the 3-DOF capacitive force sensor under different applied forces showing the displacement between the sensing cells and the grounded part (Kim et al., 2018a). © 2018 IEEE. Reprinted, with permission. (H) Exploded view of the wrist force sensor and the electrode alignment of the three-axis capacitive force sensor at rest and under two applied forces (Lee et al., 2016). © 2016 IEEE. Reprinted, with permission. (I) Exploded view of the surgical palpation probe with the capacitance sensing PCB configuration and one case in which change in capacitance is generated by the capacitance sensing cells when Z-axis force is applied (Kim et al., 2018b). © 2018 IEEE. Reprinted, with permission.

Furthermore, the proposed design entails no moving parts, eliminating the need for more complex machinery that may lead to reliability issues. In an experiment to validate the sensing function in identifying the relative hardness of 6 different elastomer samples, the piezoresistive design could differentiate the hardness of three samples. However, it failed to distinguish the relative hardness of three other samples of relatively similar hardness. This proved the design’s reliability in identifying materials with considerable hardness differences, making it suitable for palpation for more pronounced tumors but unsuitable for more hidden or obscure ones.

Atieh et al. (2011) attempted to make a piezoresistive-based multifunctional sensor that could simultaneously measure the contact forces of the grasper tool, as well as the relative hardness of the material. Relative hardness was measured when an abnormally concentrated load was detected by the sensor, indicating a physically affected tissue with the possibility of a tumor. Silicone rubber samples of varying hardness were used to simulate human tissues, proving the potential of the sensor to distinguish a range of silicone rubber samples.

Three-dimensional force sensors have also been developed and fabricated by silicon MEMS technology for compactness. Mei et al. (2000) developed a compact, yet robust, piezoresistive sensing system with a soft contact surface capable of measuring up to 50 N of force. Force concentrating silicon columns positioned on the piezoresistive sensing cells were enclosed within rubber surfaces to absorb shock for the inner devices and circuitry (Figure 2B). An asymmetric strain distribution on the membrane of the 4 × 8 sensing cells was key to detecting three-dimensional forces. The design was optimized to measure forces from all directions and stresses on all zones of the sensor. Calibration to 0.5% error was performed through weight loading, and further steps were taken to ensure force detection in the X, Y, and Z directions. For 0–50 N of forces on the Z-axis and -10–10 N of forces on the X- and Y-axes, the final sensor achieved a 2% full-scale accuracy, indicating reasonable force detection in all three dimensions. Integration onto laparoscopic tools for MIS is yet to be determined, but such a study poses the possibility of measuring shear forces with high accuracy within MIS-acceptable force ranges through piezoresistive sensors.

While one of the prominent ways in which surgeons can judge whether tissue has a tumor is through MIS palpation with a laparoscopic grasper, Kattavenos et al. (2004) took a different approach to this medical practice by developing a sweeping force sensor. In this study, sensors were composed of a one-dimensional array of eight resistors (measuring 10 × 40 mm2), each with an individual sensing area (0.5 × 0.5 mm2). The sensor was secured onto a forceps jaw, where it swept across a phantom bowel several times in order to build a visualization of where irregular lumps of varying intensities, sizes, and gaps were. This sweeping-for-detection technique, as opposed to the grasping-for-detection, proved its feasibility in experimentation, but it required several “sweeps” in order to build a full image of possible tumor locations on the tissue. A similar feat was demonstrated by Naidu et al. (2016), who developed a low-cost disposable palpation tactile sensing device using piezoresistive sensors covering a 36 × 10 mm2 sensing area. The study focused on uncovering tumors of sizes smaller than 25 mm because larger tumors are known to be easily detectable without tactile sensation aids. The piezoresistive array required the sensing area to span the diameter of a tumor and come in contact with healthy surrounding tissues. An algorithm was implemented to detect whether there was an abnormal area of force detected on the sensor relative to its environment, indicating the possibility of a tumor. Detected pressure differences of above 40% of the maximum average pressure setting were indicated by red regions on the computer-simulated image.

Further testing was done to ensure that the cyclic loading on the sensor and stress relaxation induced errors did not significantly affect data, with the assumption of 0.3 Hz to be the maximum palpation cyclic load pattern with a 45 N maximum palpation force. Static loading of maximum forces over 15 s on the sensor showed a 16% drift on the piezoresistive sensors, suggesting that improvements need to be made to compensate for stress relaxation effects. Phantom palpation tests were performed, with silicone rubber spheres simulating tumors five times stiffer than healthy tissues, placed at different depths to examine sensor sensitivity. The system was able to detect a simulated tumor up to 10 mm deep clearly. Furthermore, tissue palpation tests were performed with six novice subjects (pre-trained with instrument operation) to locate randomly hidden tumors on a bovine liver sample. All subjects successfully reported all tumors without false positives, with a localization error of 2.2 ± 0.9 mm. The study demonstrated that the system was user-friendly for novices without MIS training. Such systems may prove useful in cases where surgeons cannot directly grasp a visible tumor or irregular tissue, but the research falls short of experimenting with excised or diseased human tissue, where detection may prove to be a greater challenge.

Taking on a more unique approach to developing a piezoresistive-based sensor for MIS, Hu et al. (2010) developed a bioinspired tactile sensor mimicking the structure and mechanism of the hair cell. Inspired by the hair cell’s ability to detect mechanical stimuli with great sensitivity and durability, the team tested a tactile sensor composed of a central silicon post, surrounded by four piezoresistive sensors (acting as strain gauges) fabricated on a thin-film polyimide diaphragm base (Figure 2C). Due to mechanical stimuli, the tilting of the central silicon post led to deformation on the diaphragm base, which was measured by the four piezoresistive sensors. Excessive shear stimuli (bending) were resolved by building a cylindrical wall, limiting the central posts’ displacement. A balanced trade-off was made between building a high central silicon post with high sensitivity but poor durability. The final fabricated sensor measured 3.5 N−1 and 10.8 N−1 of normal and shear force sensitivities. The force experienced by the central post is usually much smaller than that of the total force applied on the entire sensor, making the sensor suitable for MIS. The sensor was able to detect a minimum of 0.046 and 0.017 mN of normal and shear forces, making it capable of detecting minimal force changes. However, the shear force measurement was limited to a 0.05 N maximum. Finally, a scratching test was performed using rubber fingers to prove that data on scratching patterns (direction, speed, and intensity) could be recorded by an array of sensors. With high-sensitivity normal and shear forces detection, the sensor was ideal for 3D force applications. Although promising in terms of specifications, more work is required to process signals from the sensor on-chip (within the MIS tool) in order to prevent wires from interfering with MIS. Integration onto a laparoscopic instrument can then be made possible, and the feasibility of the system fully demonstrated and optimized for MIS.

Realizing the importance of protecting electronic circuits of the force sensor from the surgical environment (with organs, bodily fluids, blood), as well as preventing the contamination and infection of a patient from the laparoscopic tool in MIS, Radó et al. (2018) focused on piezoresistive sensor development on creating an appropriate elastomer coating. Polydimethylsiloxane (PDMS) coating was selected for its elastic and sterilizable properties. The PDMS coating of a perpendicular load sensor led to an increased sensitivity deviation of from ±3% to ±10%, with a delay in the response time from 36 to 60 µs. It is suspected that the tendency of PDMS to conform while deforming, as well as elastomer hardening across certain regions, led to these deviations. The system was later attached to a Robin Heart surgery robot, but the study did not indicate specific tests or experimental results performed.

As one of the most mature and developed mechanical sensing technologies, piezoresistive force sensors are low-cost, have shape versatility, and can reliably produce force data. They are relatively flexible, durable, and consume relatively little power. However, issues such as increased noise and decreased sensitivity arise when these force sensors are miniaturized (Wang et al., 2005). Smaller, thinner piezoresistive sensors are also more prone to fragility and hysteresis error. Despite this, researchers were able to show that this technology is feasible in commercial surgical systems through implementing piezoresistive tactile sensors in surgical graspers. For example, Atieh et al. (2011) suggested that these sensors could detect a range of tissue hardness values required for palpation. Another implementation included the fabrication of a sweeping piezoresistive sensor array that was used to accurately detect tumors up to 10 mm deep without false positives on bovine liver samples (Kattavenos et al., 2004). Other non-surgical related studies have shown the ability of piezoresistive sensors to detect three-dimensional forces, which could be useful for measuring shear forces with high accuracy. Although well-studied and researched, more testing of piezoresistive force sensors in actual clinical settings is needed to determine its worthiness in MIS.

4.2 Piezoelectric Tactile Sensing

Piezoelectric force sensors rely on the piezoelectric effect, wherein imposed mechanical forces onto a piezoelectric element lead to measurable generated charges that can be harvested as the output voltage (Tzou and Tseng, 1990). Each given force corresponds to a certain charge across the sensing elements. An amplifier converts this to an output voltage proportional to the pressure. Applications range from force and pressure detection to acceleration and vibration measurements (Damjanovic, 1998). Conversely, converse piezoelectric sensors can harvest vibrations and movements into stored energy (Roundy and Wright, 2004; Ng and Liao, 2005). The basic relationships of the direct and converse piezoelectric effects can be described by the piezoelectric constitutive equations, represented by the following equation (Tadigadapa, 2010):

and

where is electrical displacement, is the mechanical stress, is the permittivity, is the electric field, is the mechanical strain, is the Temperature, is the elastic compliance coefficient, and is the elastic stiffness constant. The superscript on one parameter indicates when another parameter is held constant, such as , which represents the elastic compliance coefficient under a constant electric field. The piezoelectric coefficients and correspond to a 3 × 6 matrix, where the indices (i = 1–3) define the normal electric field or displacement orientation, (j = 1–3) define normal mechanical stresses or strains, and (j = 4–6) represent shear strains or stresses. Another important figure of merit in piezoelectric materials is the electromechanical coupling coefficient, k, representing the ratio of the mechanical (electrical) energy converted to the input electrical (mechanical) energy for the piezoelectric material. The coupling coefficient is the square root of the following equation (Tadigadapa and Mateti, 2009):

Commonly found piezoelectric elements include mainly natural and human-made crystals (quartz, salts, and topaz) or ceramics (Jaffe and Berlincourt, 1965; Damjanovic, 1998). The piezoelectric material holds certain axes of polarity, allowing the propagation of the piezoelectric effect (Gallego-Juarez, 1989). These crystal properties, including its lattice structure and cut shape, allow for generating of voltage potentials that can distinguish normal, longitudinal, and shear forces (Tiwana et al., 2012). When the piezoelectric element is deformed by applied pressure, the induced polariztation and, subsequently, generated voltage are directly proportional but decay through time dictated by the material’s dielectric constant and impedance (Gautschi, 2002; Tiwana et al., 2012). This makes such a sensor design ideal for dynamic forces (especially at high-frequency) but renders it ineffectual when measuring static forces over an extended period of time.

In fact, the use of the piezoelectric effect has matured within medicine in the past three decades through a field called piezoelectric surgery (Labanca et al., 2008). Piezoelectric surgery utilizes vibrational ultrasonic frequencies to cut through hard tissues while keeping soft tissue intact (Siervo et al., 2004; Schaller et al., 2005). This minimally invasive technique lowers risks associated with oral and maxillofacial surgeries, making it one of piezoelectricity’s most impactful contributions (Labanca et al., 2008).

The main advantages of piezoelectric sensors include high stability (when single crystals are used), reproducibility, and linearity (Gautschi, 2002). Its frequency can range from 1 Hz to the MHz level, allowing it to detect high-frequency motions (ideal for vibrations). Such sensors possess one of the highest span-to-threshold ratios (over 108), allowing a great measuring range from mN up to kN (Tressler et al., 1998). Due to the piezoelectric material’s composition, the sensor is also rendered mostly unaffected by changing electric and magnetic fields in the surgical environment (Tressler et al., 1998; Gautschi, 2002). Their ability to be compacted and embedded within health monitoring systems makes them ideal for medical implementation (Sirohi and Chopra, 2000). Likewise, complex shapes and large areas can be easily realized (Tressler et al., 1998).

The major drawback of the piezoelectric force sensor is, as discussed earlier, its inability to measure static forces over long periods of time. To measure static forces over a long duration using piezoelectric properties, perfectly insulating materials and near-zero internal resistance are needed to prevent the constant electron loss in the sensor. Partially static measurements are made possible using a single crystal as the piezoelectric medium (Gautschi, 2002). Water-soluble crystals used in piezoelectric sensors may also become susceptible to highly humid environments. Charges from the surrounding environment (if the piezoelectric material is exposed) may affect measurements as well. Its temperature sensitivity may also lead to inaccurate measurements and crystal deformation due to the thermal expansion and temperature-dependent properties of the pyroelectric, piezoelectric materials (Zhang and Yu, 2011). Fortunately, its temperature sensitivity can be disregarded in MIS environments.

Polyvinylidene fluoride (PVDF) is one of the most widely applied piezoelectric elements used in force sensing integration in MIS due to its ability to be manufactured into thin sheets (Puangmali et al., 2008). Dargahi et al. (1999) reported a microfabricated tactile sensor for MIS that can both detect the magnitude and location of applied forces on a commercially available laparoscopic grasper. Results showed that the sensor had high linearity and decent sensitivity of 0.1 N. However, to avoid damage to the sensor, the maximum tested load was 2 N per sensing element. MIS forces can reach up to 35 N, so ideally, sensing elements should have a greater range. Although the developed PVDF-based tactile sensor could be attached without altering the original laparoscopic grasper, the design was proven to be complicated and cumbersome and, therefore, unsuitable for easy commercial integration.

Miniaturized specifically for MIS integration, a multifunctional PVDF-based tactile sensor was made by Sokhanvar et al. (2007). A total of three PVDF sensing elements were implemented onto the tissue grasper, two of which were attached on the ends of a flexible beam to determine force magnitude and position, while a third sensing element was attached to the center of the beam to measure material hardness. Softness characterization was made calculable through the values read from the two end sensors and the deflection/stress induced on the center sensor. Softer grasped materials led to larger beam deflections. The sensor was validated both analytically and numerically, and it was indicated that the results were satisfactory with theoretical data with high sensitivity and MIS-appropriate range. It should be noted that the results also indicated that a trade-off between the range of stiffness and resolution had to be made. To achieve an ideal balance between sensitivity and resolution, properties of the flexible beam (material, length, and thickness) would have to be altered according to the specific surgery. In addition, only dynamics loads were tested. Further work is needed to be done to micromachine the sensor and test it with more complex soft tissues to analyze the device-tissue friction.

Qasaimeh et al. (2008a) advanced the concept further by improving the design and miniaturizing it using MEMS technologies. The team developed a fully micromachined PVDF-based sensor accommodating the full range of forces associated with MIS (Figure 2D). In the jaw design, a patterned PVDF film was sandwiched between a micromachined silicon layer with tooth-shaped protrusions and a Plexiglas layer. A 200 µm gap between the PVDF film and Plexiglas layer was made in order to allow for the silicon plate to deflect upon object contact. Upon contact, plate deflection stretched the attached PVDF, providing voltage output and, subsequently, force readings. Three sensing units, each composed of two sensing elements at the silicon plate supports and one on the silicon plate bridge, made up the complete sensor. This design allowed the sensor to measure both magnitude and relative position on the contact force on the sensor. Simulations were carried out, showing that the sensor was able to detect hidden irregularities within a grasped object. Sudden changes in force or uneven uniformity of measured force indicated the presence of lumps. Softness estimations of different elastomers were carried out using the microfabricated sensors, with the observation that a higher grasping force leads to a smaller deviation between the theoretical and experimental calculation of the modulus of elasticity (Qasaimeh et al., 2008b). The sensorized grasper jaw also exhibited the ability to detect small forces from simulated pulsating arteries (assumed to be dynamic, with few grams of force) while measuring large grasping forces. Moreover, since it was micromachined, it could be mass-produced with a low unit cost and be disposable (Qasaimeh et al., 2009). More realistic testing is needed to determine its ability to detect hidden tumors and other unexposed tissue features, perhaps with animal tissues.

In a study by Chuang et al. (2013), a novel approach of using a small steel ball embedded within a soft material allowed for a flexible tactile sensor for piezoelectric-based MIS. In the study, a PVDF film detected different physical properties of objects by determining uneven stress distributions from the applied force due to the stiffness difference between the steel ball and PDMS. Such a sensor was used to characterize different soft tissues of animal organs by hardness through cyclic loading of the material. For softness estimation of gripped organs using a smart MIS grasper, a further comparison of the obtained results with an experimentally generated database of each organ and tissue is worth every effort (Azizi et al., 2018). Ultimately, recognizing the tissue and the maximum force that the surgeon can apply on it is possible.

In a proof-of-concept study, Sedaghati et al. (2005) took a different approach to determine the compliance of tissues in MIS through a cylindrical PVDF design. Two cylinders were used: a phenolic rigid cylinder was wrapped with a larger, soft rubber deformable cylinder (Figure 2E). A PVDF film between the rigid cylinder and base plate was used to capture the forces experienced by the rigid cylinder. Another PVDF was placed between the two rigid Plexiglas plates (beneath the two cylinders) to measure the total applied force. The prototype and experiment proved that by determining the ratio of the force applied onto the rigid cylinder to the total measured force on the sensor, the softness of the object could be determined. Good agreement was found between the tested results and finite element results. Although the current prototype exhibits high sensitivity and linearity, miniaturization has not been proven yet, rendering the current sensor design unsuitable for MIS integration. Sedaghati et al. (2005) acknowledged this drawback and noted that a miniaturized sensor may face accuracy concerns and could be damaged by large shear forces. Further investigation regarding this piezoelectric force sensor design is needed.

A similar design of using rigid and compliant cylindrical bodies to determine the viscoelastic characteristics of tissues was studied by Narayanan et al. (2006). As opposed to previous piezoelectric-based sensors studied by Dargahi et al. (1999), Dargahi (2002), and Dario et al. (1984), which measured tissue compliance exclusively, the proposed sensor was designed to measure both compliance and viscous damping in tissues. Because tissues are viscoelastic, Narayanan et al. (2006) deemed the development of a sensor capable of determining viscosity as important for improved tissue characterization and modeling. Testing was performed to verify the sensor. It was found that rapid loading and unloading cycles of the target material were required to determine the viscoelastic properties of the material. Because the ability to find the viscoelastic property increases with the increased loading rate, real-life palpation would require fast grasps on different parts of tissue in order to determine viscosity. Although the concept is proven, such a system would be impractical in its current state if mounted onto endoscopic or laparoscopic graspers in surgery.

Meanwhile, several researchers particularly attempted to measure forces applied by catheters and endoscopes, as these instruments are commonly used in MIS. In Chuang et al. (2016)’s work, a miniaturized tactile sensor was made suitable for mounting on the tip of an endoscope to detect submucosal tumors by hardness assessment. This PVDF-based piezoelectric tactile sensor involved a copper ball embedded in soft packaging, where the voltage ratio obtained from the hard inner ball and soft packaging layers indicated the hardness of the contacted object. They claimed that this sensor is safe to be used for actual endoscopy due to the passive nature of the sensing element, as well as using the biocompatible PDMS for packaging.

Another innovative approach towards integrating PVDF piezoelectric tactile sensors into miniaturized systems was explored by Li et al. (2008)., in which a high-sensitivity dome-shaped flexible sensor was fabricated and tested. The study presented a novel “mold-transfer method” to producing piezoelectric polymer films that could easily be fabricated to conform to any given shape, making it ideal for a wide range of biomedical applications. The micromachined mold, which matched the shape of the desired application surface, was formed, spin-coated, applied with the piezoelectric polymer solution, and then integrated onto the actual device itself. For a bump-shaped design, polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) was used for the polymer solution, and SU-8 was used for the bump mold. For fabrication of the dome-shaped film, PVDF-TrFE solution was spin-coated onto cyclic-olefin-copolymer lens molds. A protective layer of parylene film acted as a thermal isolator to avoid temperature and pressure variations associated with ferroelectric materials. Dynamic forces at 5 Hz were successfully tested with the sensor for loading ranges between 20 mN and 1 N. Force increments of 40 mN (for the bump-shaped sensor) and 25 mN (for the dome-shaped sensor) could be measured. The study illustrated an easier way to fabricate miniaturized biomedical tactile sensors and proved its high-sensitivity capabilities for simple force measurements. Forces encountered within MIS are often more complicated, so further developments are needed to give the fabricated sensors the ability to determine the shape, location, and hardness of tissues. Direct applications such as tissue palpation and tissue property detection were not discussed.

Outside of the more popularly used PVDF, Lee et al. (2014) selected piezoelectric polycrystalline lead zirconate titanate (PZT) for enhanced sensitivity when integrated with a micro-structured PDMS element. The proposed structure was composed of a top glass plate with four stress-concentrating columns with the PZT sensor layer as the base (Figure 2F). The four individual piezoelectric force sensors below the glass columns allowed both force direction (shear) and location to be easily measured. Moving forces could be detected, and the design was miniaturized with MEMS technology, allowing the simple sensor to be applied for biomedical tactile applications. Although the proof of concept was complete, actual experimentation with LS or palpation was not tested, suggesting that more work is needed to determine its usefulness in either practice in detecting hidden lumps or irregular tissues.

Ottermo et al. (2004) also selected PZT piezoelectric sensors for their ability to be easily miniaturized into an array of 30 sensing elements (3 × 10) to measure forces and their locations. The described work was intended for an augmented MIS, in which a tactile display installed onto the physician’s finger would reflect forces and shapes grasped by the tissue. However, such a design lacked the ability to tell tissue hardness, and the tactile feedback was not proven useful to physicians. Issues encountered during the prototyping phase included the narrowness of the sensing area and challenging integration with the tactile display. Such a proposed concept has yet to be created and tested.

Other advanced piezoelectric sensors were designed in a spiral-shaped structure for the estimation of tissue hardness using catheters. For instance, the sensor developed by Zhang et al. (2017) consisted of a square spiral metal plate designed to reduce the sensor’s resonant frequency and, therefore, restrict the impact brought by the effective mass of the tissue. The number of the sensor’s components was reduced using one ceramic of PZT as both an actuator and a sensing element. The detection of a lump inside a silicone sample was demonstrated after successfully verifying the sensor’s ability to measure hardness. A further miniaturized and optimized sensor was presented later, having a circular sensing element of a spiral shape with an outer diameter less than 8 mm, which was integrated on the tip of a catheter (Ju et al., 2019). However, one drawback was the change in the sensor’s sensitivity with the change in the hardness of the tested samples. This type of measurement is classified as frequency-domain tactile sensing.

Piezoelectric sensors offer many important advantages, including stability, reproducibility, and linearity, that make them suitable for many force detection operations. The sensor can be easily compacted and is unaffected by changing electric and magnetic fields, making it ideal for medical implementations (Sirohi and Chopra, 2000). Although they can be temperature sensitive, the range of piezoelectric thermal expansion associated with MIS is not significant enough to lead to inaccurate measurements. A drawback of piezoelectric tactile sensing that also deserves attention is its inability to measure static forces over extended periods of time (Gautschi, 2002). Despite this, PVDF has been widely used for MIS grasper integration in research with considerable success. Qasaimeh et al. (2008a) fabricated a PVDF-based jaw sensor that was able to detect small, hidden irregularities in objects but fell short of actual clinic testing. Li et al. (2008) proved that PVDF sensors could be miniaturized and molded into different shapes while preserving their high-sensitivity capabilities for simple force detecting tasks. Many similar studies worked on placing these sensors into arrays or different shapes but did not do much in actual clinical testing. Advanced and miniaturized systems, e.g., piezoelectric needle sensor, can be useful for tissue diagnosis by revealing the biomechanical variations of tissues caused by lesions, e.g., human thyroid (Sharma et al., 2019). For piezoelectric tactile sensing to play a major role in LS in the future, researchers need to further prove its versatility and efficacy in detecting tumors and more complicated shapes in clinical settings.

4.3 Capacitive Tactile Sensing

Capacitive sensing has acquired an extensive interest in circuit design for its high electrical sensitivity, excellent repeatability, low power consumption, compact layout, linear response, simple device construction, and immunity to temperature variation and thermal noises, in comparison to its piezoelectric and piezoresistive counterparts (Zhou et al., 2005; Chi et al., 2018). Recently, capacitive sensors were introduced to a wide range of biomedical applications, such as bio-analytical detectors (Wongkittisuksa et al., 2011), smart implants (Iqbal et al., 2019), prosthetic skins (Mannsfeld et al., 2010), and wearable electronics (Pan and Wang, 2011). Typically, capacitive sensors consist of pairs of electrodes separated by a dielectric medium. The value of electrical capacitance, , of parallel-plate capacitor can be calculated by the following simple, well-known governing equation:

where is the vacuum permittivity, is the relative permittivity, is the area of electrodes, and is the distance between electrodes. The relationship between the magnitude of the applied normal force, , on the two parallel plates and the output voltage, , of the capacitor is written as follows (Bao and Bao, 2000):

In capacitive tactile sensors, the applied mechanical loading, e.g., pressing or stretching, compresses the spring-like dielectric material and changes the effective area of and the distance between the two electrodes of the capacitor. Therefore, the dielectric layer is designed to be highly deformable, allowing the capacitive sensor to be responsive to minimal compressive loadings. In particular cases, the dielectric properties of the medium separating the electrodes can be changed by an external load, i.e., forcing another material of different permittivity into the sensing element. Eventually, the capacitance of the sensor will be altered. Circuitry translates the measured capacitance change into force differential and retrieves the mechanical signal. Basically, the measurement range and sensitivity of the sensor can be adjusted by changing the compliance of the dielectric material, e.g., PDMS elastomers with different mixing ratios (Lei et al., 2014).

In one demonstration, a flexible, capacitive tactile sensor array was developed using PDMS as a base material with the capability of measuring both normal and shear force distributions,(Lee et al., 2008). The design of each tactile cell incorporated a large bump on top of a pillar structure formed at the center between the air gap of four capacitors. Applied normal forces induced an equal capacitance change across all capacitors, whereas shear forces corresponded to a capacitance increase in two elements and a countereffect on the adjacent ones. The individual sensor cell within the proposed setup showed sensitivities of 2.5%, 2.9%, and 3.0%/mN in the X, Y, and Z directions, respectively.

Recent advances in photolithography techniques can enhance the spatial resolution and reduce the overall thickness of capacitive sensors by miniaturizing the sensing elements and eliminating the need for adhesive layers between capacitive plates (Pritchard et al., 2008). Additionally, the performance of capacitive tactile sensors can be improved by developing well-designed electrodes. High-performance, flexible capacitive tactile sensors were achieved using a bottom micropatterned elastomeric electrode fabricated by coating ultrathin sliver-nanowires (AgNWs) onto the PDMS layer with uniform microtower patterns (Wan et al., 2018). The high aspect ratio and low density of the micropatterns make them easier to deform than solid dielectric films, leading to an increased pressure sensitivity of 1.2 kPa−1.

Several capacitive tactile sensor arrays have been mounted on MIS graspers to measure the exerted force by the surgeon during procedures. In Ottermo et al. (2006)’s work, an array of 15 × 4 thin capacitive pressure sensing elements was fixed onto a grasper jaw that offered the detection of pressure distribution in a range up to 7 N/cm2 with 2 mm spatial resolution. While conventional graspers usually have a serrated surface, the smooth surface of the proposed sensor array escalated slippage occasions and created more problems for the inexperienced subjects. Nevertheless, delivering visual feedback of the tactile image was totally helpful for discriminating between objects of different hardness and sizes. Towards satisfying both compatibility and electrical constraints of clinical implementation, Paydar et al. (2012) fabricated a capacitive sensing device with a material choice of parylene C and gold for the insulating dielectric medium and capacitive sensing plates, respectively. MEMS processes of lithography and chemical vapor deposition were employed to fabricate the thin-film capacitive sensors, providing a miniaturized, low-profile, biocompatible solution for measuring forces as a basic component of tactile feedback systems for MIS.

The shape and functionality of MIS graspers can be preserved by integrating the sensor underneath the surface of the jaws. Kim et al. (2014) proposed restoring the tactile sensation via a pair of dual axial force sensors. Each sensor was made of two capacitive sensor units adhered to the surfaces of a triangular prism portion of the jaw. Here, the upper electrode plates of the sensing units were designed to be larger than the bottom electrodes to eliminate the nonlinearity in capacitance change concerning the electrodes’ overlapped area. Each jaw with a single sensor can extract force measurements along the normal and one longitudinal direction out of the differential signal of the capacitive sensing units. With the reading from two orthogonally oriented sensors, the forceps can estimate a 3-axial pulling force and a single axial grasping force. Thorough analyses of the sensing principle and the force transformation method were addressed (Kim et al., 2015), showing errors of 0.1 N with good repeatability and low hysteresis. Performance verification of the proposed sensing system consisting of a four-axial joint, tool shaft, joint actuation unit, and sensorized forceps was carried out using Raven-II, an open-source surgical robot platform. Pulling and grasping forces were estimated based on the measured cell forces, and the transformations closely matched that of a reference sensor with slightly higher noise. Yet, the proposed design focuses on tissue handling with the front portion of the inner surface of the sensorized forceps.

With the aim of measuring forces other than ones applied to the inner surface of the jaws, Kim et al. (2018a) came up with the unique idea of installing two compact 3 degrees-of-freedom (DOF) sensors at the proximal region of the forceps jaws (Figure 2G). Each capacitive-based force sensor was constructed out of orthogonal and parallel arrangements of capacitance-sensing units in a triangular structure. Using a transformation matrix with a geometric relation to the forceps, two 3-DOF forces measured by the sensorized forceps were transformed into grasping force, 3-DOF manipulating force with a palpation function, and rotational torque. The proposed sensorized forceps were taken one step further by compensating for some environmental factors, including effects of humidity, temperature, and high voltage (Seok et al., 2019). For humidity, a fourth capacitive unit was integrated within the original structure of the sensor, where its capacitance was solely influenced by humidity. As a result, the sensor can eliminate the humidity noise from the force readouts of the three other capacitive units. Since temperature influences were linked to the induced parasitic capacitance between the ground and different capacitive cells separated by the printed circuit board (PCB) layer of dielectric nature, an AC shielding layer was inserted in-between to prevent the force measurements from being affected by the change in temperature. Lastly, blocking high voltages that cause damage to the sensor was achieved by immersing the aluminum-based forceps in an acidic electrolyte to energize its surface and produce an outer layer of nonconductive aluminum oxide. Experimental results illustrated error-free grasping force under the electro-cautery process.

So far, installing sensors onto the grasping tip has been the most common way to measure the grasping force during MIS. Alternatively, the measurement of forces applied during MIS, i.e., manipulation force and grasping force, can be detected via sensors placed either at the wrist, shaft, or base of the tool. These positions offer a larger space for sensor placement and reduce the size constraints of the tactile sensor design. In this regard, Lee et al. (2016) presented a 4-DOF grasping tool with a miniaturized wrist force and torque sensors for tissue manipulation sensing (Figure 2H). The wrist force sensor was made up of a PCB of three discrete in-plane lower electrodes sharing a common electrically grounded metal disc as an upper electrode. For grasping force measurement, two torque sensors were embedded into the driving pulleys. Once torque is applied, the gap distance between the sensing electrodes is reduced, resulting in a measurable change in the capacitance. With both sensors, three-axis manipulation force and single-axis grasping force measurements were obtained. Subsequently, system-level validation through 1 min experiments of pulling and releasing an elastic tissue object repeatedly in arbitrary directions was performed using Raven-II. The prototype showed a well-matching response to that of a reference sensor. However, the elastic body used for assembling the wrist force sensor limits the sensing range to 1 N; hence, an enhanced design or more robust material must be considered.