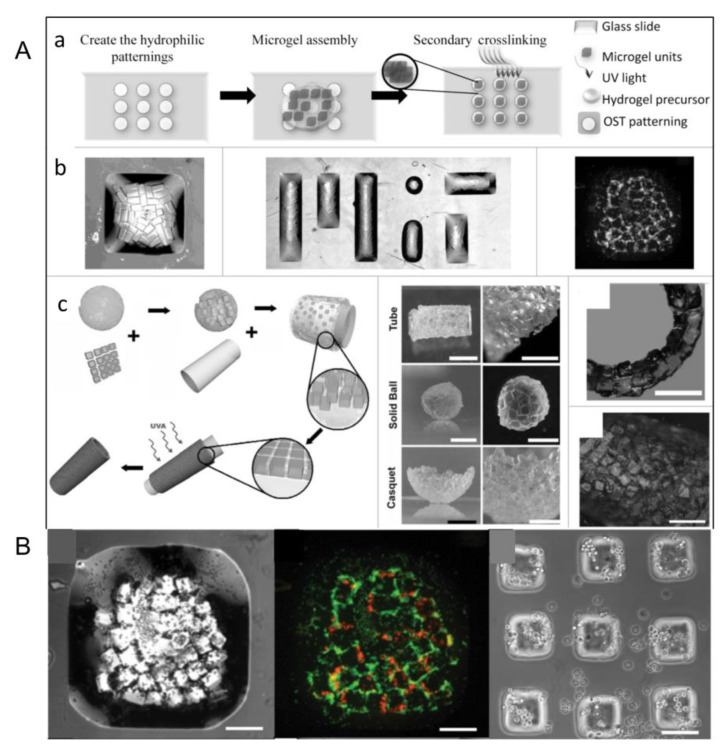

Figure 13.

(A) Directional assembly of cell-loaded microgels in water droplets on surfaces with hydrophobic and hydrophilic regions. (a) Driven by surface tension, hydrophilic microgels aggregate in patterned water droplets that are confined within the hydrophilic pattern and stabilized by secondary cross-linking. (b) By controlling the size and shape of the surface pattern, well-structured microgel assemblies are formed on the glass slide. Stably assembled microgels can be easily obtained from the surface, and finally, multicellular tissue structures can be obtained. (c) To make microgel assemblies with complex shapes, microgels of a specific shape are first mixed in a prepolymer solution and deposited on the surface of PDMS treated with oxygen plasma. Due to hydrophilicity, the liquid wetted the surface and drove the microgel subunit to cover the PDMS surface. After the excess prepolymer solution is removed, microgels are assembled into tightly packed sheets on the surface of the template (bottom-right corner). Complex-shaped microgel components, such as tubes, spheres, and shells (right). A further application of the method has also shown the construction of larger structure in a layer-by-layer manner, in which double-layer tubes with diameters of 5 mm are made. Hepatocytes (HepG2) are encapsulated with PEG microgel and assembled into tubular structures. (Reproduced with permission from the Reference [25]). (B) Cell-loaded microgels are assembled by using block hydrogels of specific shape. The morphology and viability of the cell-loaded microgels are stained before assembly and 24 h after culture. (Reproduced with permission from the Reference [59]).