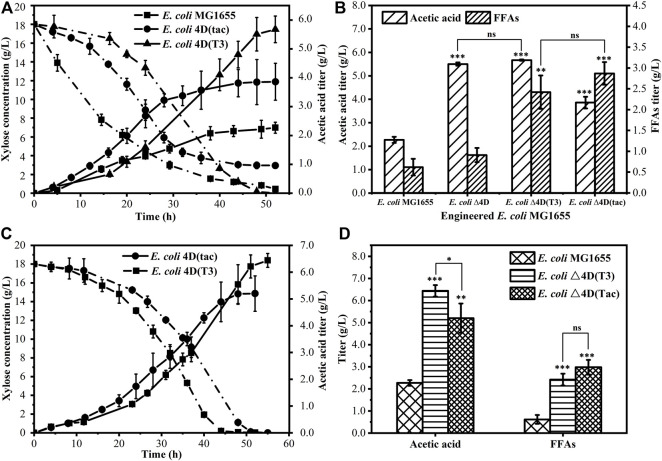

FIGURE 3.

Production of acetic acid and fatty acids by engineered E. coli in a bioreactor (A) Process diagram of E. coli MG1655, E. coli Δ4D (T3), and E. coli Δ4D (tac) using xylose to produce acetic acid in a bioreactor (B) acetic acid and FFAs titer obtained by fermentation of E. coli MG1655 and engineered E. coli, and the cultivation time was 55 h (C) Process diagram of E. coli Δ4D (T3) and E. coli Δ4D (tac) using xylose to produce acetic acid in a bioreactor after optimization of the nitrogen source (D) Comparison of the titers of acetic acid and FFAs obtained by fermentation of E. coli MG1655 and engineered E. coli, and the cultivation time was 55 h. The error bars indicate the standard deviation of triplicate experiments. *p < 0.05; **p < 0.01; ***p < 0.001; ns, no significance.