Abstract

Meniscal tears are a frequent orthopedic injury commonly managed by conservative strategies to avoid osteoarthritis development descending from altered biomechanics. Among cutting-edge approaches in tissue engineering, 3D printing technologies are extremely promising guaranteeing for complex biomimetic architectures mimicking native tissues. Considering the anisotropic characteristics of the menisci, and the ability of printing over structural control, it descends the intriguing potential of such vanguard techniques to meet individual joints’ requirements within personalized medicine. This literature review provides a state-of-the-art on 3D printing for meniscus reconstruction. Experiences in printing materials/technologies, scaffold types, augmentation strategies, cellular conditioning have been compared/discussed; outcomes of pre-clinical studies allowed for further considerations. To date, translation to clinic of 3D printed meniscal devices is still a challenge: meniscus reconstruction is once again clear expression of how the integration of different expertise (e.g., anatomy, engineering, biomaterials science, cell biology, and medicine) is required to successfully address native tissues complexities.

Keywords: Meniscal tears, 3D printing and bioprinting, printable biomaterials, ultrastructure, tissue engineering

Introduction

The menisci are critical components of a healthy knee joint1,2 as exerting a pivotal role in preserving the knee homeostasis 3 and biomechanics through load transmission, shock absorption, stability, nutrition, joint lubrification, and proprioception.4–6 Consequently, meniscal damage affects knee equilibrium, progressively contributing to cartilage disruption up to osteoarthritis (OA) responsible of pain, loss of joint function, and musculoskeletal morbidity.5,7,8 To date, considering meniscal poor-self healing potential, 9 its repair represents a formidable challenge to orthopedic surgeons.

Efforts in biomechanical/clinical research require a meniscus-preserving strategy instead of meniscus-resection10,11 which often lead to poorer clinical outcomes up to total knee arthroplasty. 6 In particular, degenerative changes showed to be directly proportional to the amount of meniscus removed; which, in consideration of this, should be minimized preferring a repairing or a replacing approach.4,12 Surgical techniques and allograft transplantation were the primary attempts to meniscus repair13–15; however, these procedures display intrinsic limitations in clinical practice as, often, the occurrence of partial or even total meniscal resection is an imminent need.

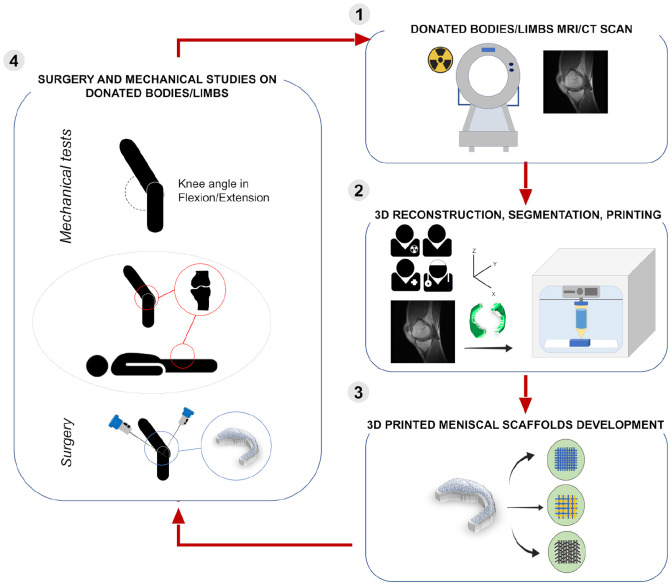

To counteract the increasing incidence rate of meniscal injury, innovative, and effective repair strategies are required 16 and among vanguard approaches, 3D printing technologies seem to be intriguing and promising. Reviewing the literature, the interest that 3D printing/bioprinting applied to tissue engineering is gaining, appears particularly evident. Development of bone and cartilage scaffolds,17,18 thyroid cartilage supports, 19 engineered nasal cartilage implants, 20 dentin-pulp substitutes, 21 devices for adipose tissue regeneration, 22 as well as hydrogel systems for biomedical applications 23 are only few examples. As highlighted by Rongen et al. 24 in an interesting review article focusing on biomaterials for meniscus substitutes, the ideal scaffold should satisfy some basic requirements. These include mechanical and tribological properties, resembling that of the native meniscus; an adequate shape and size (preferably customized according to patient needs); biocompatibility of the materials used for scaffolds fabrication without leading to cytotoxicity during resorption; biomimicry; favorable porosity satisfying both mechanical stability and cell colonization requirements; adequate degradation profile. Despite still far from clinic, printing approaches for meniscus reconstruction are rapidly developing and great attempts are currently ongoing to meet the criteria above. In particular, extensive research is directed toward the identification of biomaterials, ink/bioinks formulations, cell types able to guarantee for satisfactory outcomes, and future translation to clinic.

Considering this scenario, the aim of this systematic revision of the literature is to provide the state of the art on 3D printing technologies for the manufacture of meniscal substitutes; as the key for successful devices resides on the ability to replicate anatomy, a framework on meniscus macroscopic and microscopic organization is preliminary presented to focus the target tissue and describe the peculiar characteristics that must be sought. Thus, after considering the common meniscal ruptures and currently available approaches (with their limits), an overview on 3D printing technologies is provided to get a basic understanding of 3D printing.

Meniscal scaffolds must assure a balance of shape, biomechanical function, and biocompatibility to guarantee tissue replacement success. Four different categories of devices may be recognized considering the main characteristics of the 3D printed/3Dbioprinted supports reported in the literature: (a) synthetic 3D printed bare scaffolds; (b) synthetic 3D printed conditioned scaffolds; (c) 3D bioprinted scaffolds; (d) synthetic 3D printed + 3D bioprinted composite scaffolds.

To date, the choice and the identification of the most adequate meniscal substitute still represent a challenge and an unmet need. 25

The menisci: From anatomy to function

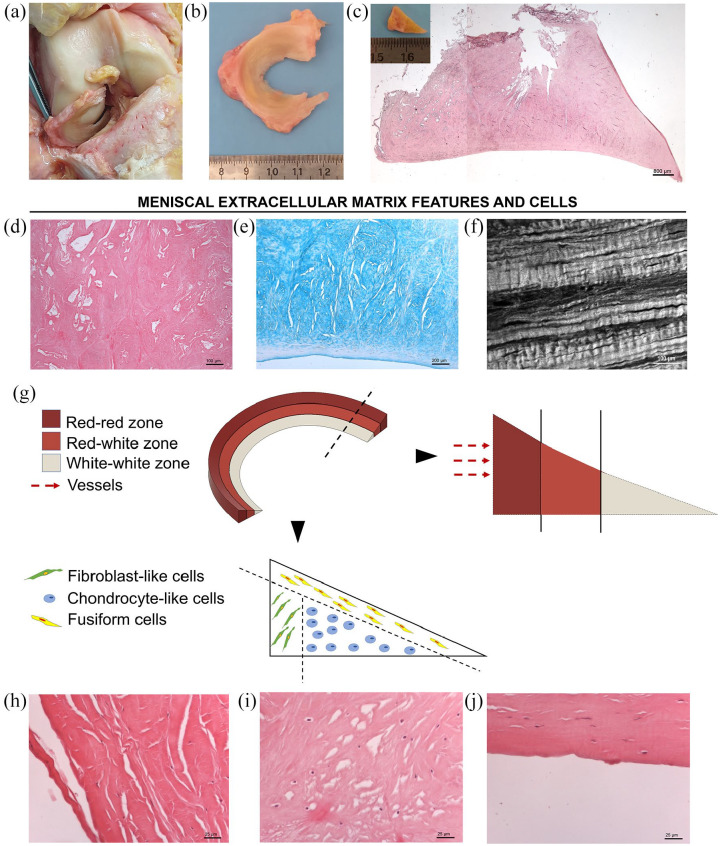

An engineered meniscus should mimic the structural and biochemical organization of the native tissue to assure for the proper environment and mechanical support able to guide functional regeneration26,27; thus, knowledge of macroscopic and microscopic anatomy is imperative for successful reproduction of the tissue-specific characteristics through vanguard technological approaches 28 (Figure 1). Additionally, considering 3D bioprinting strategies including cellular elements in bioinks formulations, consciousness on resident cells phenotype, and peculiar spatial organization may guide in developing effective bioprinted devices.

Figure 1.

Representative macroscopic and microscopic anatomy of the lateral meniscus (LM). (a) Anterior view of human right knee in flexion. After dissection and removal of patellar ligament and patella, the knee was subluxated showing the LM position between the femoral condyle and the tibial plateau. (b) Gross appearance of the LM soon after excision (superior view), showing its typical crescent C-shape profile, thicker peripherally. (c) Representative section of the LM stained with Hematoxylin and Eosin (H&E). Insert: gross appearance of the tissue in cross-section showing its characteristic triangular shape. (d and e) Extracellular matrix details by H&E (d) and Alcian Blue (e) staining for tissue organization and sulfated glycosaminoglycans/glycoproteins identification, respectively; (f) meniscal tissue appearance by Second Harmonic Generation Microscopy showing the specific orientation of collagen fibrils within the tissue through a label-free approach. (g) Schematic diagram representing the three different areas identifiable in the meniscus, according to vessels distribution: red-red zone; red-white zone; white-white zone; moreover, also specific cells distribution is represented, distinguishing localization of fibroblast-like cells, in the outer zone; chondrocyte-like cells, in the center of the meniscal tissue; fusiform cells, in correspondence of the superficial margin of the meniscus. (h–j) Histological appearance of meniscal cells by H&E. (h) Fibroblast-like cells display long cell extensions; (i) chondrocyte-like cells show a round shape; (j) fusiform cells has no cell extensions (scale bars: 800 μm (c); 100 μm (d and f); 200 μm (f); 25 μm (h–j)).

Macroscopic and microscopic anatomy

In the knee joint, the lateral meniscus (C-shaped) and the medial meniscus (more semicircular shape) are fibrocartilaginous structures, roughly triangular in cross section. They cover approximately the 70% of the tibial plateau articular surface 5 and they show a unique composition and structure. 29 The peripheral, vascular border of each meniscus is thick, convex, and attached to the joint capsule. The innermost border recedes to form a thin free edge. Superiorly, the menisci articulate with the convex femoral condyles, inferiorly they accommodate the tibial plateau.30,31

The menisci receive blood supply by the branches of the popliteal artery, the medial, and the lateral middle geniculate arteries, respectively.29,31,32 Vascularization allows to identify here three distinct zones: the vascularized red-red zone, located in the outer edge of the meniscus; the partially vascularized red-white zone, located in the middle; the avascular white-white zone, in the innermost area of the meniscus. 29 Only 10%–30% of the medial meniscus and 10%–25% of the lateral meniscus are directly vascularized.31,33,34 Nutrition of the central portions of the menisci (i.e. white-white and red-white zones) depends on synovial fluid diffusion, a mechanism sustained by the intermittent loading/release of stress mediated through body weight and muscular force.29,35

Innervation of the menisci has the same distribution of vascularization; the capsule of the knee is penetrated by the branches of the posterior tibial nerve, obturator nerve, femoral nerve, and the common peroneal nerve.29,32,36,37 Nociceptive free nerve endings are contained in the peripheral two-thirds of the menisci, while different mechanoreceptors are identifiable in the anterior and posterior horns29,32,37 suggesting a proprioceptive function.

According to meniscal anatomical organization, in case of injury, while repair of the outer region is successful, meniscal lesions affecting the inner portion of the tissue often lead to partial meniscectomy. 38

As for menisci resident cells, three main subpopulations have been identified according to the different meniscal regions and specific cell morphology 39 : (a) fibroblast-like cells with elongated morphology in the outer meniscal area, (b) chondrocyte-like cells with oval to round shape in the inner region, and (c) fusiform cells aligned parallel to the meniscal surface in the superficial zone. Meniscal cells can be detected as isolated, in pairs or in short rows, being either randomly arranged or aligned in longitudinal rows between dense collagen fibers; while the outer two-thirds of meniscal area resemble fibrocartilage organization (cells interconnected by gap junctions), the inner one-third of the tissue presents hyaline cartilage arrangement, with unconnected cells. 40

While most meniscal cells exhibit a CD34−/CD31− phenotype, the fusiform cells of the superficial area were found to be CD34+, suggesting that they might be specific progenitors responsible for therapeutic and regenerative effects.41,42 In fact, CD34 is acknowledged as a marker of mesenchymal stem cells (MSCs) with high regenerative potential, also expressing alpha-smooth muscle actin (α-SMA).43,44 Based on that, CD34+/α-SMA+ meniscus cells have been proposed to participate in the reparative process of pathological menisci. 42

The ECM composition of normal human menisci mainly consists of water (70%–80%); as for the remaining portion (20%–30%), it is represented by collagen (50%–75%) and glycosaminoglycans (GAGs) (15%–30%). 39 Type I collagen constitutes more than 90% of collagen content, being distributed throughout the whole meniscus, from the peripheral to inner area, and organized in circumferential fibers.45,46 On the other hand, collagen type II is predominantly localized in the inner avascular zone, showing an organized network of circumferential and radial fibers. 46 Variable amounts of types III, IV, V, and VI collagen can also be detected within the meniscus. 45 Collagens were demonstrated to be primarily responsible for the tensile strength of menisci. 30

Besides collagen, other matrix proteins include fibronectin, which is known to regulate many cellular processes (i.e. tissue repair, embryogenesis, blood clotting, and cell migration/adhesion) and elastin, which is supposed to interact with collagen to ensure for tissue resiliency. 39

Proteoglycans form an organized network mainly localized in the inner zone of the meniscal tissue. The glycosaminoglycan profile of the normal adult human meniscus consists of chondroitin-6-sulfate (40%–60%), chondroitin-4-sulfate (10%–20%), dermatan sulfate (20%–30%), keratan sulfate (15%), and hyaluronic acid (3%). 39 Adhesion glycoproteins like fibronectin and thrombospondin connect meniscal cells with the surrounding ECM. 46 GAGs are more concentrated in the meniscal horns and inner zone of the tissue, which correspond to the primary weightbearing areas. 30 Being characterized by high specialized structure, high fixed-charge density, and charge-charge repulsion forces, proteoglycans in the meniscal ECM are suggested to be responsible for tissue hydration, as well as its ability to bear compressive loads, providing the meniscus with the typical viscoelastic mechanical behavior.30,39

Menisci function and biomechanics

During normal daily activities, the knee joint is loaded by up to five times body weight 47 withstanding different types of forces including shear, tension, compression, and hydrostatic pressure.1,48 The menisci, by virtue of their specific wedge-shape, can bear this total joint load (from 45% to 75%) with variations associated to the degree of joint flexion and the health of the tissue. 49 In particular, the horn attachments allow for conversion of the vertical compressive forces to horizontal hoop stresses. 1

Joint load and mechanical factors play a key role in meniscus homeostasis, orchestrating the biological activity of meniscal cells in both physiological and pathological conditions. 48 It descends that a profound consciousness about the mechanobiology of the meniscus is fundamental not only to manage the onset and eventual progression of meniscal degeneration but also for the identification, design, and manufacture of optimal meniscal replacements to restore normal tibiofemoral contact pressure in the knee joint.50,51

For a true classification of meniscal tissue properties, avoiding variability among species, human meniscal specimens have specifically to be considered. 50 The meniscus resists axial compression with an aggregate modulus of 100–150 kPa. As for the tensile modulus of the tissue, it is about 100–300 MPa in circumferential direction and 10-fold lower radially. Finally, the shear modulus of the meniscus is approximately 120 kPa. 1 The menisci also enable effective articulation between the femoral condyles and the tibial plateau 5 leaving 1 mm space in the articulating surface, with only 10% of contact between femur/tibia; this anatomical organization allows controlling stress on the articular cartilage 52 and is necessarily altered when meniscectomies occur. Studies considering the biomechanical effects of meniscectomies within the joint showed an increase of 235%–335% in peak local contact load in case of total removal of the lateral meniscus 53 ; >350% in contact forces on the articular cartilage in partial (16%–34%) meniscectomy 54 ; and overall increase in contact forces by two to three times, following total meniscectomy. 55

To effectively maintain their load-bearing function, the menisci can partly move when the knees are in flexion. For human weight-bearing knees, the reported displacements (medial/lateral meniscus, mean ± SD) are anterior-posterior displacement of the anterior horn 7.1 ± 2.5/9.5 ± 4.0 mm and that of the posterior horn 3.9 ± 1.8/5.6 ± 2.8 mm and a radial displacement of 3.6 ± 2.3 mm/3.7 ± 1.7 mm. 24

Other functions associated to the menisci are shock absorption (mediated by their ligamentous fixation to the femur and the tibia), 56 lubrication of the knee joint, nutrition supply to the articular cartilage and proprioception.57–59

Ligaments (i.e. medial collateral ligament, the transverse ligament, and the meniscofemoral ligaments) good shape and tight are a prerogative to assure an effective meniscal function. 56

Tears and current treatment options overview

Meniscal tears, showing a bimodal age distribution in young and elderly people, have an incidence per year of 60–70 per 100,000 population. 5 As for etiopathogenesis, it can be either (a) acute traumatic: mainly in healthy knee joint, if left untreated may lead to secondary OA 60 ; (b) chronic degenerative (can also be asymptomatic): mainly in elderly people, within compromised or abnormal joints/menisci. OA is surely a predisposing factor being account as a “whole joint disease”.61–63 Additionally, age alone is a critical (and unavoidable) risk factor too.64–68

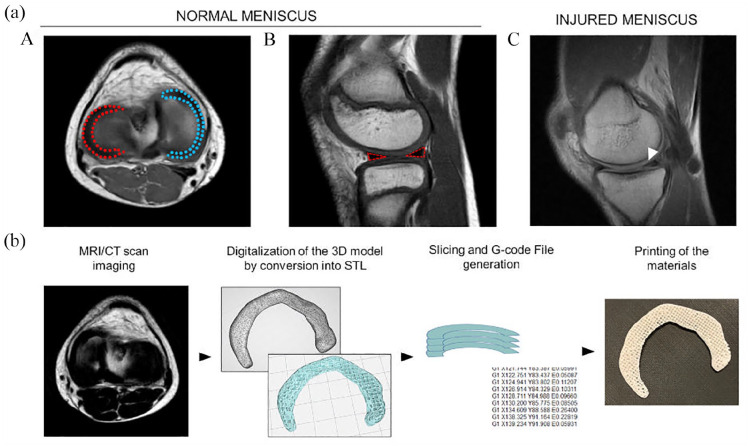

Typical meniscal tears distinguish five patterns clearly recognizable trough Magnetic Resonance Imaging (MRI); these include radial, horizontal longitudinal, vertical longitudinal, oblique, and a complex combination of multiple patterns. The healthy meniscus typically experiences longitudinal tears, bucket-handle tears (vertical split and in line with the orientation of the circumferential collagen fibers), or radial tears (perpendicular split to the long axis). Degenerative meniscal tears are mainly horizontal-cleavage lesions or complex characterized by thin, lesioned, and fibrillated margins (Figure 2). 60

Figure 2.

(a) Magnetic resonance imaging of the knee. (A and B) Normal menisci (lateral meniscus: red-dotted; medial meniscus: blue-dotted) and (C) injured meniscus. Specifically, sagittal T1 weighted image reveals a horizontal tear of the posterior horn of the medial meniscus (white arrow). (b) Flow-diagram describing the methodological steps required to print a tissue (i.e. meniscal tissue) from Magnetic Resonance Imaging (MRI)/Computed Tomography (CT). STL: Standard Triangulation Language.

Treatment options range from non-surgical interventions (i.e. physical therapy) to surgical interventions including meniscectomy (total and partial performed open or arthroscopically), meniscal repair, and meniscal reconstruction.69,70 Nowadays, total meniscectomy is never performed as a primary procedure as predisposing to degenerative changes up to early OA.69,71,72 Partial meniscectomy is suggested in case of radial tears at the white-white zone and degenerative meniscal tears displaying mechanical symptoms with no response after 3–6 months to non-surgical approach and after radiological evaluation. 73 Therefore, in accordance with data based on clinical experience, meniscal repair, or non-removal procedures in traumatic tears should be the recommended choice to achieve tissue healing.69,74 .

Considering repair approaches, different suture types can be adopted69,75–77 and biological approaches (augmentation techniques) can also be used in combination to enhance the healing response (augmentation by platelet rich plasma (PRP) and platelet rich fibrin (PRF) clot derivatives78,79; trephination, abrasion, and rasping; wrapping80,81). The main drawback with conventional suture techniques relays on long operating time and difficulties in surgery. Therefore, meniscal allograft transplantation (MAT) or more recent meniscal scaffolds have been developed to overcome these issues.

MAT, mimicking the typical loading pattern of the knee, significantly reduces compartment contact pressures thus protecting from cartilage degeneration. 53 However, they are not free from limitations (allografts preparation/preservation, 82 meniscus sizing,82,83 possible graft failure, extrusion, infection, arthrofibrosis, the need for reoperation, aseptic synovitis, hematoma, limited range of motion, joint effusion, and bone plug loosening 84 ). Moreover, MAT is not the preferred approach following partial meniscal resection as meniscal scaffolds can induce fibrocartilage tissue. 85

Commercial scaffolds

To date, three commercial scaffolds are available to reconstruct the segmental meniscus defects 86 and they belong to two categories: collagen-based implants (Menaflex—ReGen, USA, also known as the collagen meniscus implant CMI®—Ivy Sports Medicine, Germany) and synthetic polymer-based implants (Actifit®—Orteq Ltd., London, UK; NUsurface®—Active Implants, LLC., Memphis, TN, USA).

Menaflex CMI® is crescent-shaped spongy device which can be adjusted to fit the meniscal defect area prior to be sutured to the remaining native meniscus in arthroscopy. It is made of lyophilized and cross-linked purified type I collagen from bovine Achilles tendon, enriched with hyaluronic acid and chondroitin sulfate.87,88 The Actifit® is a biodegradable, synthetic, acellular implant in aliphatic polyurethane and polycaprolactone.88,89 It has meniscal shape; prior to be arthroscopically implanted and sutured to the meniscal wall and residual meniscus, Actifit® can be cut to match the size of the defect. 90 Both Menaflex CMI® and Actifit® are adequate in case of partial meniscectomy. Their implant occurs without prior cell seeding; however, they have a proper ultrastructure allowing for optimal resident cells colonization and fibrocartilage ingrowth in turn reducing risk of OA development. After tissue reconstitution, degradation of the implant progressively occurs.87,89 NUsurface® Meniscus Implant is a non-anatomically discoid-shaped, free floating and non-anchored meniscal prosthesis designed for total replacement of the medial meniscus. It is made from polycarbonate-urethane (PCU) reinforced with high tensile Ultra High Molecular Weight Polyethylene (UHMWPE) fibers, allowing to mimic and restore the natural contact pattern of pressure distribution within the medial meniscus. 91

Although these scaffolds are designed to stimulate the growth of new tissues or mimic the function of the natural meniscus, the best meniscal scaffold type remains controversial92–94 and additional research is required. 70

Clinical failure (e.g. infections, mechanical failure, chronic synovitis development, need for a second surgery) is reported in up to 8% and 32% for the CMI and Actifit®, respectively. As for NUsurface® Meniscus Implant evidence-based clinical data are still largely absent and FDA approval for it is still pending. 11

To date, there is consensus that only a substitute which closely matches normal meniscal tissue properties can re-establish meniscal functions. 95 Improvement in structure and material design is the direction for advances in surgical meniscal treatment assuring for stable devices that, while bearing the load, also promote meniscal repair and reconstruction.

From additive manufacturing technologies to 3D bioprinting strategies for tissues customization

3D printing technologies, also known as additive manufacturing (AM) technologies or 3D rapid prototyping technologies (i.e. binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat photopolymerization) represent interesting and emerging approaches to mimic key structural and functional properties of different human tissues from a patient’s own medical images,96,97 thus overcoming the limits of the traditional methods for manufacturing 3D scaffolds (electrospinning, freeze-drying, gas foaming, particle/porogen leaching).

However, due to inability of AM technologies to print cell-loaded materials, 3D bioprinting methods emerged as intriguing alternatives, distinguishing for a more biological approach to design/manufacture 3D scaffolds.

3D bioprinter technologies can print cell-free natural polymers—the “bio-paper,” cell aggregates, cells encapsulated in hydrogels, or cell-seeded microcarriers formulated as “bioinks”.98,99 Typically, biomaterials for 3D bioprinting are soft and mechanically weak hydrogels with thermo-sensitive properties but endowed with intrinsic biological properties allowing for cell colonization. Fusion chambers, prior used to melt polymer filaments, are here converted in pneumatic-based extruders; print head can be equipped with heating/cooling elements to guarantee for tunable print conditions according to different types of bioinks. Nozzles are substituted with needles and piezoelectric elements, while print beds are equipped with cooling and UV light elements to avoid collapsing of low viscosity bioinks.99–103

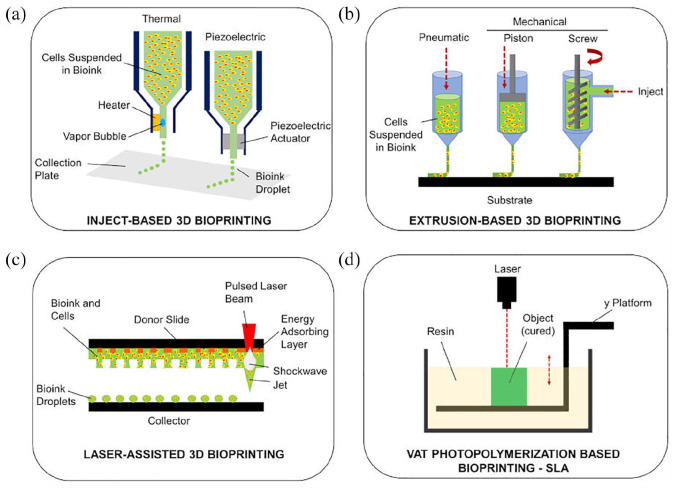

In bioprinting, different technologies can be identified according to the bioink dispensing method: inkjet-based 3D bioprinting, extrusion-based 3D bioprinting, laser-assisted 3D bioprinting,104–108 vat photopolymerization-based bioprinting109,110 (Figure 3).

Figure 3.

3D bioprinting technologies. Schematic representation of the main technologies identifiable in 3D bioprinting: (a) inkjet-based 3D bioprinting, (b) extrusion-based 3D bioprinting, (c) laser assisted 3D bioprinting, and (d) vat photopolymerization-based bioprinting (SLA: stereolithography).

Inkjet-based 3D bioprinting

Inkjet-based methods employ cells or biomaterials instead of the ink used in the existing commercial inkjet printers; moreover, a moving stage is present instead of paper.

According to the actuator type, inkjet-based 3D bioprinters distinguish the thermal jetting systems and the piezoelectric jetting systems. 111 The actuator generates a pressure overcoming the surface tension at the noozle opening, thus inducing the ejection of the bioink droplets (10 µm) deposited in a “bottom-up” manner. Bioinks are required to show low viscosities (10–100 µm) to avoid small nozzle clogging. Cell density cannot be high; a shear viscosity of 30 MPa s is the upper boundary of what is “safely” printable though this approach. 112

In the thermal heater method (or bubble-jet method) the materials are turned into ink droplets at the nozzle by heat. Heating generates small air bubbles in the printhead and their collapse allows for ink drops eject. 113 Controlling temperature and/or modulating pressure pulses frequency it is possible to exert control over droplets size and volume. This approach is adequate for structures requiring high control over ultrastructure.

In the piezoelectric actuator method, ink droplets are created through voltage application to the piezoelectric elements. Despite this approach guarantees for great control over droplets size, the cells are likely affected by the physical impact thus compromising cell membrane integrity. Considering this issue, thermal jetting is often preferred over the piezoelectric-based method. 112

The inkjet method is low cost and it guarantees for short fabrication time (printing speed: 1–10,000 droplets/s). Unfortunately, the obtained products are stiff, and the layers cannot be stacked very high. Moreover, denaturalization of the biomaterials and inconsistent ink droplets can also occur.108,112,114,115

The use of different materials has been reported, these include in example alginate, gelatin, collagen type I, fibrin, polyethylene glycol, gelatin methacrylate (GelMA).

Extrusion-based 3D bioprinting

Extrusion-based methods work dispensing bioink in a continuous filament to produce a 3D structure organized in a layer-by-layer manner 112 ; printing speed is set at 0.1–150 mm/s 108 According to the dispensing method, pneumatic-extrusion bioprinters or mechanical-extrusion bioprinters can be distinguished; moreover, the mechanical-extrusion bioprinters can also be divided in piston-systems or screw-driven systems. 116

In general, extrusion methods can print materials within a viscosity range value of 30–25 × 103 MPa s. Applying the pressure, it is expected a reduction in bioink viscosity, thus allowing its deposition, followed by a prompt increase in viscosity soon after the removal of the shear force. Gelation must occur immediately after deposition to guarantee for scaffold structure maintenance; however, this depends on the hydrogel solution. In fact, in presence of high water content, the bioink may flows after printing leading to low resolution structures (40–1200 µm). To overcome this limit, affecting resolution, hydrogels with high viscosity or with self-assembling characteristics can be adopted; in parallel, cross-linking during extrusion, the use of a co-extrusion or thermoplastic reinforcement or the extrusion of bioinks in a secondary structure called suspension bath (providing support during gelation) can be adopted. 112 Other critical issues include frequent blockage of the nozzles and shear-induced cell death (cell viability ranging from 60% to 90%).108,117

Highly viscous materials are generally approached with screw-driven systems; piston- or pneumatic-based extrusion systems are typically used with lower viscosities.

Extrusion-based approaches has been reported in example with alginate, gelatin, gellan gum, guar gum, methylcellulose, collagen type I, matrigel, fibrinogen, collagen methacrylate, GelMA, elastin, polycaprolactone (PCL), polyethylene glycol (PEG), polyvinyl alcohol (PVA), and polyvinyl acetate. 108

Laser-assisted 3D bioprinting

Laser-assisted methods allows to obtain different structures through a laser, without presence of a nozzle. Together with the pulsed laser source, the other components include a ribbon, serving as a support for the printing material, and a support to collect the printed material. Briefly, the ribbon is a thin absorbing layer of metal (e.g. gold or titanium) coated onto a laser transparent support (i.e. glass). The bioink is deposited at the surface of the metal film; once the laser pulse induces metal film vaporization, the bioink reaches the collector in the form of droplets. 112

Printed materials can be both solid and liquid even though hydrogels are preferred. Despite the existence of possible issues in cells viability ascribable to high levels of thermal energy, controlling intensity/extent of laser exposure guarantees for good performances (viability, ⩾90%) associated to high printing speed (1–2000 mm/s) and resolution (40–100 µm). Low efficiency has been encounterd in fabricating high 3D layering.108,118

Vat polymerization-based bioprinting

Vat polymerization-based bioprinting, the most common of which is stereolithography (SLA), is constituted by a building platform, a vat of photopolymer resin, and a light source for resin irradiation. Specifically, according to the irradiation approach, two methods can be recognized: the vectorwise and the mask irradiation. Both a top-down printing and bottom-up printing can be adopted.109,119

In the vectorwise, scanning galvanometers scan the resin surface through a ultraviolet (UV), infrared (IR), or visible light lasers beam. Photopolymerization occurs at the scanned regions thus leading to resin solidification. Once the first layer is built, the building platform descends inside the vat to allow for recoating with resin and subsequent photopolymerization. Each layer is built one by one .109,112,118

In the mask irradiation approach the entire resin surface is irradiated, solidifying in a single step. This strategy allows for more complex structures than vectorwise SLA. Many different photopolymers and cell-laden hydrogels can be used when adopting this bioprinting technique: no particular rheological characteristics are required (upper suspension viscosity limit, 5 Pa s; lower limit, sufficient enough to prevent cells homogeneous and stable distribution).109,112,119

To promote photopolymerization, specific crosslinking agents can be included within the bioink (e.g. methacrylates, azides). Moreover, careful attention must be paid to the gelation strategies as cells viability may be affected by them. To overcome this issue, two-photon polymerization (2PP) has been introduced to fast this phase. 2PP guarantees for high control over ultrastructure. 112

Among the materials used in SLA can be recognized acrylated PEG, PVA, chitosan, GelMA, Allylated gelatin (GelAGE), methacrylated hyaluronic acid, silk fibroin (SF).109,119

Bioinks formulations and critical issues

3D bioprinting technology mainly relies on advanced 3D bioprinters (for details on 3D printing methods see the paragraphs above) and effective cell-laden bioinks. 120

Cell-laden bioinks are based on polymeric materials (with/without additives and/or crosslinking agents); besides cells encapsulation they are required to assure for their viability, homogeneous distribution and proliferation. Thus, they do not act as an inert carrier, but they constitute the microenvironment which will significantly affect cells behavior within the 3D structure and the leading agent responsible for 3D structure integrity.121–123

To guide the formulation of an ideal bioink, consciousness is mandatory on the characteristics that it is expected to be endowed with. Specifically, these include adequate rheological features, ability to provide a proper biocompatible micro-environment mimicking the target tissue, a controlled biodegradability compatible with dynamic cellular remodeling of the construct. Moreover, due to cellular presence, it is also expected a certain control over shear-thinning behavior (for minimal stress to cells during extrusion), sol-gel transition, and extrudability without clogging the nozzle. Thus, the printed structure is required to show satisfactory mechanical strength and rigidity matching that of the implant site, shape fidelity, and proper ultrastructure (pore size) to support constructs bioactivity (diffusion of oxygen, carbon dioxide, and nutrients).124–127

Since identifying the optimal cell-laden bioink formulation is the crucial step for successful bioprinting, several formulations have been attempted (Tables 3 and 4). In example, considering a bioink for extrusion-based bioprinting, it is initially in a bulk resting state, then it experiences a transition to a high shear condition while passing through the nozzle, and finally it is required to assume a new and stable resting shape after extrusion. All these transitions must take place in a respectful manner toward cells. 123

Table 3.

3D bioprinted scaffolds.

| Authors and references | Printing method/parameters | Printing material | Additives or bioink | SHAPE and/or DIMENSIONS — PORE SIZE µm/ POROSITY% |

Cells | Scaffold characterization studies | In vitro cells/scaffold interactions | In vivo studies |

|---|---|---|---|---|---|---|---|---|

| Luo et al. 97 | 3D MRI model of human medial meniscus 3D CAD Mimics software (Materialize 21, Belgium) 3D Custom Bioprinter Parameters. Needle Ø: 22G; print T: 25°C; bed T: 4°C; speed: 3 mm/s. |

— | Bioink: gelatin + alginate + cellulose nanofibers (in different proportions) + cells (5 × 106 cells/mL) | - Square blocks (15 × 15 × 2 mm) - Meniscus-like (48.3 × 40.5 × 8.28 mm) MESH: 40% infill rate and rectilinear filling pattern |

Rabbit MFCs (Passage: 3–4) | - Rheological characterization [− cells] - Printability [− cells] by SEM |

Static culture

- Cell viability and metabolic activity - Histology (calcium, COL, GAG) and IHC (COL I/II/X) |

— |

| Narayanan et al. 130 | MRI of medial knee meniscus 3D CAD (Materialize, Mimics) 3D Bioprinter (Bioplotter, EnvisionTEC GmbH, Germany) Parameters: - STUDY 3: nozzle Ø: 200 µm; print T: 50°C (Nozzle); speed: 18 mm/s; P: 0.12 N/mm - STUDY 4: nozzle Ø: 300 µm; print T: 37°C (Nozzle); speed: 12 mm/s; P: 0.03 N/mm |

— | Bioink: Alginate + cells (5 × 106 cells/mL) | - 20 × 20 × 3mm - Meniscus-like MESH: laydown orientation, 0°/90° in three layers |

hASCs (Passage: N.R.) | - Cell viability | — | — |

| Rhee et al. 131 | CT scan of scaffolds 3D CAD (Solidworks; Dassault Systemes,Velizy France) 3D Custom Bioprinter. Parameters: bed T: 37°C. |

— | COL hydrogel+cells (10 × 106 cells/mL) | - Shape/dimensions: anatomic shape scaffold (sheep meniscus;

geometric shape scaffold—half cylinder) MESH: — |

- Bovine MFCs (Passage: 0) | - Cell dispersion by confocal reflectance - Mechanical behavior, compression |

Static culture

- Cell viability |

— |

| Filardo et al. 134 | MRI scans of a human volunteer. 3D CAD (Mimics, Materialize) 3D InkJet Bioprinter (3D discovery printing tool, RegenHU). Parameters. print T: 37°C; speed: 12 mm/s; P: 0.2 bar. |

— | Bioink: LifeInk 200, Collagen I bio-ink (Advanced Biomatrix) + cells (38 × 106 cells/mL) |

Meniscus-like MESH: height for each layer, 0.25 mm, rectilinear pattern with 50% density |

- Human BM-MSCs (Passage: 3–4) | — |

Static culture

- Cell viability |

— |

| Markstedt et al. 138 | CT-scan of sheep meniscus models 3D CAD (Mimics, Materialize) Ink Jet Bioprinter (3D Discovery). Parameters. Nozzle Ø: 300 µm; print T 25°C; speed (10–20 mm/s); P: 20–60 kPa. |

— | Bioink: Nanofibrillated cellulose and alginate + cells (15 × 106 cells/mL) |

- Small grid, 7.2 × 7.2 mm2

- Large grid 38.5 × 17.7 mm2 - Solid disk 8 mm Ø, 1.5 mm high - Human ear, 22 mm (long axis) - Sheep meniscus 18 mm (long axis) MESH: grid shape |

- Human nasoseptal chondrocytes (Passage: 1) | - Mechanical behavior, compression - Cytotoxicity |

Static culture

- Cell viability and distribution |

— |

| Costa et al. 139 | 3D CAD model 3D custom bioprinter (integrated tissue-organ printing) Parameters. For Gellan gum/fibrinogen bionks Nozzle Ø: 240 µm; speed: 250mm/min; P: 45–65 kPa For SF methacrylate bioinks Nozzle Ø: 300 µm; speed: 250 mm/min; P: 450–550 kPa. |

— | Bioink (sequential co-printing): Gellan gum/fibrinogen + cells and SF methacrylate (1.5 × 107 cells/mL) |

10 × 10 × 5 mm3 constructs MESH: grid shape; interstrand distance, 500 µm |

Porcine meniscus cells | - Rheological measurement - Swelling - Mechanical behavior, compression - Diffusion testing - SEM |

Static culture

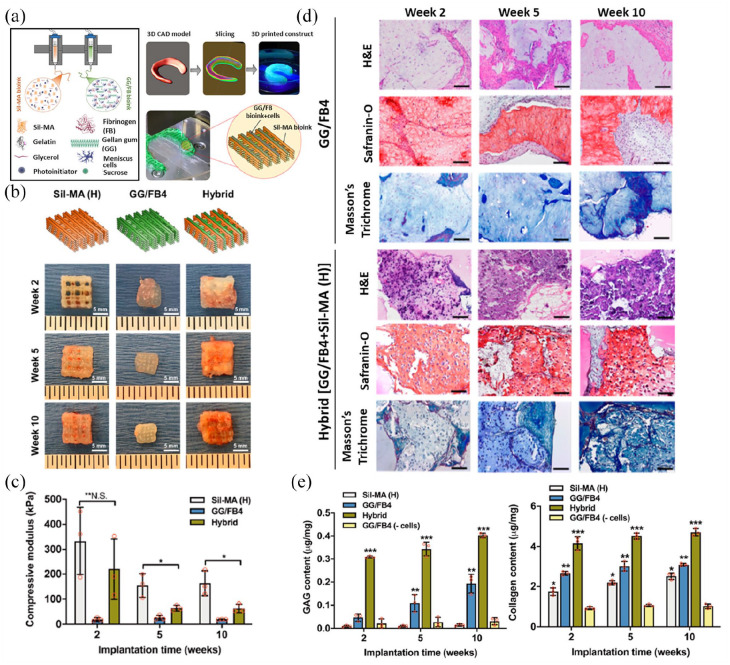

- Cell viability and proliferation - Quantitative GAGs and COL contents - Histological analysis (COL I/III) |

Subcutaneous implant (nude mice) [+

cells] Culture before implant, N.R. End point: 2, 5, 10 weeks Fibrocartilagineous tissue formation (COL I/III) - Gross appearance Biomechanical analysis, compression - Histological analysis (GAG, COLI/III) - COL fibers allignment |

| Bandyopadhyay and Mandal, 2019157 | MRI of human knee 3D CAD (3D Slicer) 3D Bioprinter (BioX, Cellink). Parameters. print T: 25°C; bed T: 4–5°C; print speed: 6–8 mm/s; P: 185–200 kPa. |

– | Bioink: SF_Gelatin | Meniscus tri-layered model, 6 × 6 × 1 mm MESH: Circumferential layer (bottom), radial lamellar layer (medial), thin mesh layer (top) |

- Porcine MFCs (Passage: 2) | - Swelling - Enzyme-assisted degradability - SEM - Mechanical behavior, compression |

Static culture

- Cell viability and proliferation - DNA and sGAG content - Total COL content - Gene expression studies (aggrecan, SOX-9, COL Iα/IIα) - Histological analysis (cell morphology, sulfated proteoglycans, total COL) - Immunogenic response (macrophage stimulation and IL-1β release) |

Subcutaneous implant (rats) [−

cells] End point: 7, 14 days - Histological and IHC for biocompatibility (cellular and macrophages infiltration) |

BM-MSCs: bone marrow mesenchymal stem cells; CAD: computer aided design; COL: collagen; G: gauge; GAG: glycosaminoglycans; hASCs: human adipose derived stem cells; IL: interleukin; kPa: kilopascal; MFCs: meniscal fibrochondrocytes; mL: milliliters; mm/s: millimeters/second; MRI: magnetic resonance imaging; N.R.: not reported; P: pressure; SEM: scanning electron microscopy; T: temperature; µm: micrometers;°C: centigrades; Ø: diameter.

Table 4.

Synthetic 3D printed + 3D bioprinted composite scaffolds.

| Authors and references | Printing method/parameters | Printing material | Additives or bioink | Shape and/or dimensions — Pore size µm/ porosity% |

Cells | Scaffold characterization studies | In vitro cells/scaffold interactions | In vivo studies |

|---|---|---|---|---|---|---|---|---|

| Chae et al. 132 | MRI of rabbit medial meniscus, 3D CAM/CAD, Custom built 3D

cell-printing system. Parameters. T: 190°C (PU/PCL melting). |

PU/PCL (60/40) Mw 43,000–50,000 Da |

Bioink: - Collagen + cells + TGFβ - Pig meniscal dECM + cells (5 × 104 cells/mL) |

- Grid-like, 5 × 5 × 1 mm - Meniscus-like 600 μm MESH: strand width, 250 µm, layer by layer stacking |

- Human BM-MSCs (Passage: 4–5) | — |

Static culture

- Cell viability and proliferation - Fibrochondrogenic gene expression (COL1A2, COL2A1, COLXA1, and aggrecan) - IF for COL1/2, aggrecan, COLX |

Subcutaneous implant (mice)

[− cells] End point: 1, 2, 4, 8 weeks - Histology and IHC (capsular thickness, foreign body giant cells, macrophages) Biocompatibility Subcutaneous implant (nude mice) [± cells] Both no culture before implant and static culture (7 d) before implant End point: 4, 8, 12, 16 weeks - Chondrogenicity, histology for cartilage, IHC for COL2 - Mechanical behavior, tensile test |

| Narayanan et al. 133 | MRI scan of medial meniscus 3D CAD (SolidWorks 2015, Dassault Systèmes, Waltham,MA; Magics (Mimics Software, Materialize v19)) 3D Bioprinting (BioplotterRP) Parameters. - Acellular alginate nanofibers and alginate nanofibers + hASC Nozzle Ø: 810 µm; print T: 37°C; speed: 5 mm/s; P: 0.02 N/mm2 - Acellular Alginate and Alginate + hASC: nozzle Ø: 810 µm; print T: 37°C; speed: 15 mm/s; P: 0.02 N/mm. |

PLA | Bioink: Alginate + cells Alginate + PLA nanofibers + cells (1.375 × 106 cells/mL) |

Meniscus-like MESH: intercalating layers of circumferentially orientated and linear parallel strand geometries; 20 layers (each 0.482 mm thick). |

hASCs (Passage: N.R.) | - Dispersion of PLA nanofibers within the hydrogel - Compression test of acellular scaffolds |

Static culture

- Cell viability/ proliferation - Histological analysis (cell distribution, COL secretion, chondrogenic differentiation, proteoglycan secretion) |

— |

| Jian et al. 135 | Micro-CT of sheep meniscus, 3D CAM/CAD (Mimics, Materialize),

Dual nozzle 3D bioprinter (Biomaker, SunP

Biotech). Parameters. Bed T: 20°C - Nozzle 1 (PCL): inner Ø: 400 µm; T: 85°C; speed: 5 mm/s. - Nozzle 2 (hydrogel): TT nozzle inner Ø: 500 µm; T: 20°C; speed: 5 mm/s. |

PCL Mw ~65,000 Da |

Bioink (dual noozle): GelMA + pig meniscal dECM+cells (1 × 106 cells/mL) |

- Primary models, 5 × 5 mm - Meniscus-like, 5 × 5 × 2.5mm. 1000 ± 50µm (PCL) thus infilled with bioink MESH: cross mesh, strand spacing (center to center) 1.5 mm |

- Rabbit MFCs (Passage: 2–5) | - SEM - Biomechanical behavior, compression, tensile testing |

Static culture

- Cell viability |

Subcutaneous implant

(mice) [− cells] End point: 2, 3, 4 weeks - Degradation Orthotopic implant (sheep) [− cells] End point: 3, 6 months - Degradation in situ - Gross evaluation - Nanoidentation and hardness test - Variations in PCL Mw - Histological (COL I/III, GAGs) and IHC (COL I) analyses |

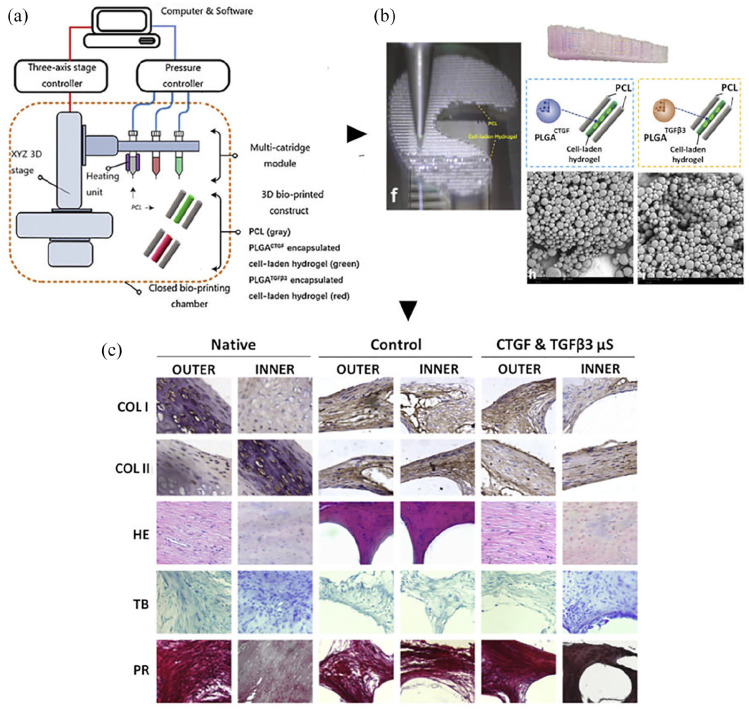

| Sun et al. 136 | 3D CAD model of goat meniscus 3D Bioprinter (Opus System, Novaprint, China) Parameters. Needle Ø: 200 µm; layer thickness: 0.2 mm; speed: 180 mm/min. |

PCL Mw N.R. |

Bioink: Cell laden hydrogel (gelatin + fibrinogen + HA +

glycerol) incapsulating PLGA microparticles carrying TGFβ3 or

CTGF (1 × 107 cells/mL) |

Meniscus-like 21.5 × 15 × 3 mm 300 µm (microchannels between PCL fibers) MESH: composite structure, cell-laden hydrogel (~100 µm Ø) + PCL (~200 µm Ø); fibers spacing, 350 μm |

Goat BM-MSCs (Passage: 2) | - SEM - Printability - Microspheres distribution - Release kinetics of TGFβ3 and CTGF and quantification - Biomechanical behavior (tensile modulus, aggregate modulus, ultimate tensile strength, radial strength, bidirectional tensile testing in radial and circumferential directions, compressive testing) |

Static culture

- Cell viability - Cell anchoring/ proliferation/distribution - Cytotoxicity - Zonal MSCs differentiation - Histology for ECM deposition (proteoglycans, COL I/III) - Expression of chondrogenic and fibrochondrogenic marker (SOX9, COL1A1, COL2A1) |

Orthotopic implant (goat) [+

cells] No culture before implant End point: 24 weeks - Mobility - Histology (Cell phenotype and tissue integrity, COL I/III, proteoglycans) IHC (COL I/II) - Cartilage and osteochondral evaluation - ICRS and Mankin grading |

| Romanazzo et al. 137 | CAD 3D modeling of scaffolds 3D Bioprinter (Bioplotter, RegenHU). Parameters. PCL Needle Ø: 25G; bed T: 65°C; P: 4 MPa. Bioink needle: 25G; P: 2 MPa |

PCL Mw 45,000 Da |

Bioink: Alginate + pig meniscus dECM + cells (8 × 106 cells/mL) | Printed construct on a coverslip About 1020 µm MESH: PCL microfibers with a ~0.36 mm thickness and ~1.02 mm spacing; layer by layer printing together with bioink |

- Porcine IFPSCs (Passage: 2) | — |

Static culture

- Mechanical behavior, stress-relaxation |

— |

BM: bone marrow; CAD: computer aided design; COL: collagen; G: gauge; GAG: glycosaminoglycans; hASCs: human adipose derived stem cells; IHC: immunohistochemistry; IL: interleukin; kPa: kilopascal; MFCs: meniscal fibrochondrocytes; MSC: mesenchymal stem cells; mm/min: millimeters/minute; mm/s: millimeters/second; MRI: magnetic resonance imaging; P: pressure; PU: polyurethane; SEM: scanning electron microscopy; SF: silk fibroin; sGAG: sulfated glycosaminoglycans; SOX9: SRY-Box transcription factor 9; T: temperature; °C: centigrades; Ø: diameter.

Despite the large number of biomaterials for TE and regenerative medicine, many of them are not compatible with 3D bioprinting strategies. 128 Only through adequate materials selection and modulating concentration, molecular weight, and crosslinking strategy, the elastic moduli of the bioinks can be tuned 107 with direct impact on the functionality of the final printed tissues and organ. As discussed above, the materials investigated for meniscal cell-laden bioinks include SF, gelatin, alginate, cellulose, GelMA, decellularized extracellular matrix (dECM), hyaluronic acid (HA), glycerol, alginate, collagen, gellan gum (Tables 3 and 4). Due to high-water content, good swelling characteristics, biocompatibility, biodegradability, and the presence of cell-binding sites, natural hydrogels are attractive for TE purposes. Optimal cells performances have been demonstrated with relatively soft and printable inks 123 which can also induce stem cells differentiation toward specific lineages by virtue of intrinsic and specific features. 129 However, hydrogels do not display significant strength and shape fidelity compared to synthetic polymers, representing a critical feature to manage. Despite variations in temperature and pressures as well as introduction of additives that may help in rheology modulation/control, the presence of cells within the bioink represents a stringent limit in the window of processing. 123 Higher viscosity assures for higher printing fidelity; however, it also leads to increased shear stress, which may impact the cells suspended in the bioink. Moreover, cross-linking strategies (i.e. thermal, chemical, physical, or enzymatic strategies also combined) could influence cells viability too, thus representing a further issue to manage. Most importantly, cell embedding itself (i.e., cell density) significantly affects the rheology of the final hydrogel: the volume occupied by cells is precluded to the hydrogel, likely exerting an effect on cross-linking efficiency and viscoelastic properties. 127

Formulating a cell-laden bioink is a delicate multistep phase which will be finally responsible for tissue construct efficiency. Intense efforts must be devoted toward the identification of a formula guaranteeing a proper equilibrium between bioink intrinsic characteristics, cellular density/survival along with the bioprinter technology adopted. Once identified the core material/materials, preliminary tests are mandatory for evaluation of different concentrations and ratios to gain satisfactory results in term of physicochemical features, printability, rheological and mechanical traits, cells distribution, and survival. In this context, also bioprinter settings (temperature, pressure, flow rate, nozzle type, crosslinking strategy) should be tested and eventually adjusted leading to an efficient formulation and a promising tissue substitute.

Referring to the cell-laden bioinks for meniscal tissue bioprinting (Tables 3 and 4) both simple (only one core material + cells)130–134 and complex (core material + additives + cells)97,135–139 bioinks were experienced. According to our knowledge, collagen was the preferred hydrogel to formulate “simple” bioinks.131,132,134 Acting on concentration and temperature it is possible to control gelation. However, the use of alginate130,133 (crosslinking by 1% CaCl2 solution) and dECM 132 (crosslinking by temperature) was also reported. Regarding “complex” bioinks, alginate was combined with gelatin and cellulose nanofibers in different proportions (crosslinking by 0.1% w/v CaCl2); higher gelatin content and cellulose nanofiber presence allowed for higher viscosity. 97 Similarly, Markstedt et al. 138 improved shape fidelity of an alginate bioink through nanofibrillated cellulose (cross-linking by 90 mM CaCl2) while Narayanan et al. 133 by PLA nanofibers (crosslinking by 1% CaCl2 solution). Romanazzo et al. 137 mixed alginate with meniscal dECM (crosslinking by 48/92 mM CaCl2). Other composite cell-laden bioink formulations were that reported by Sun et al., 136 using gelatin + fibrinogen + hyaluronic acid + glycerol incapsulating PLGA microparticles carrying TGFβ3 or CTGF; Jian et al., 135 combining GelMA with pig meniscal dECM (crosslinking by blue light, 405 nm); Costa et al., 139 proposing a sequential co-printing gellan gum/fibrinogen + porcine meniscus cells and SF methacrylate: here, gellan gum and fibrinogen lead to a stable hydrogel by a combination of ionic and enzymatic cross-linking while SF methacrylate lead to beta-sheet formation along culture time.

As for cell densities, the values are reported in Tables 3 and 4.

Synthetic and natural materials for meniscal scaffolds printing, conditioning, and bioprinting

Polymers or hydrogel precursors eventually enriched in biological factors including cells have been widely investigated for effective development of 3D printed/bioprinted meniscal scaffolds. Both synthetic (PCL,12,15,25,27,135,137,140–149 also combined with polyurethane PU/PCL 132 ; polycarbonate urethane 150 ; silicone elastomers i.e. Ecoflex30, Ecoflex50151,152; poly(desaminotyrosyl-tyrosine dodecyl ester dodecanoate) (p(DTD DD))38,153,154; poly(ethylene oxide-terephthalate)-co-poly(butylene terephtalate) (PEOT/PBT) 155 ; polylactic acid (PLA) 156 ) and natural materials (protein-based hydrogels: collagen,38,131,132,134,150,153,154,156 gelatin,27,97,135,136,141,157 silk-fibroin139,140,142,146,157; polysaccharides: agarose,27,141 alginate,97,130,133,137,138,156 hyaluronic acid,38,136,154 gellan gum 139 ; dECMs132,135,137,147) have been exploited.

Synthetic materials

PCL

PCL is an aliphatic and biodegradable polyester. 158 It has a rather low melting temperature of 59°C–64°C and a glass transition temperature of about −60°C with a degree of crystallinity up to 69% resulting in high toughness. These features, together with its rheological properties and mechanical behavior (relatively low tensile strength, 23–25 MPa; elastic modulus, 330–360 MPa), make it adequate to be widely used in melt-based extrusion printing.159–161 PCL has been extensively explored for biomedical applications by virtue of biocompatibility and a slow degradation rate (i.e. 2–3 years) mainly due to its hydrophobicity. 158 It has been also evaluated in combination (e.g. PCL-biphasic calcium phosphates). 162 In vivo, its resorption is mediated by the lipase enzyme secreted in the interstitial fluid by cells.

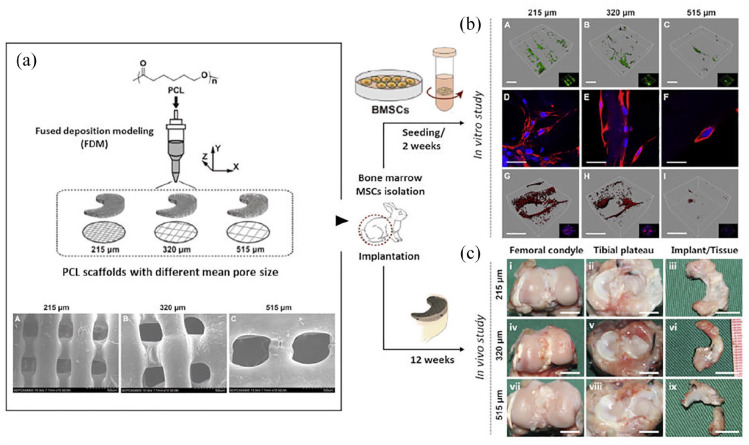

PCL is a material of choice for 3D printed meniscal scaffolds fabrication by the extrusion-based AM technique: bare12,15,25,143,144,148 and bioactivated (additives27,140–142,146,147 or bioinks135–137) PCL supports with different shapes (i.e. cylinder scaffolds,12,143,148 prism-like,27,141,144,156 cuboid-like, 142 coliseum-like, 27 meniscus-like15,25,135,136,140,141,145,147,149) have been widely reported. Different molecular weights have been used, with a lower reported limit of 43,000 Da132,143 and an upper limit of 90,000 Da. 141 As for nozzle inner diameter, the interval range was 200–516 µm. Simple grid-like meshes and more complex strands designs were both supported by the polymer (Tables 1, 2 and 4).

Table 1.

Synthetic 3D printed bare scaffolds.

| Authors and references | Printing method/parameters | Printing material | Additives or bioink | Shape and/or

dimensions — Pore size µm/porosity% |

Cells | Scaffold characterization studies | In vitro cells/scaffold interactions | In vivo studies |

|---|---|---|---|---|---|---|---|---|

| Zhou et al. 12 | MRI of rabbit leg, 3D CAM/CAD (Mimics, Materialize), FFF

3D printer. Parameters. Nozzle Ø: 317 µm, print T: 130°C; speed: 0.75 mm/s; P: 800 kPa. |

PCL Mw 80,000 Da |

— | Cylinder scaffolds, 30 × 30 × 2.5mm; 6.0 × 2.5

mm 236.5 ± 23.8 µm MESH: layer-by-layer, 0°–90° direction |

- Rat MFCs (Passage: 2–5) - Rat BM-MSCs (Passage: 2–5) |

- SEM - Water contact angle - Degradation - Mechanical behavior, compression |

Static culture

- Cell viability/proliferation - Cell morphology and attachment |

— |

| Zhang et al. 15 | MRI of rabbit leg 3D CAD (Mimics, Materialize), FFF 3D Printer. Parameters. Nozzle Ø: 317 µm, print T: 130°C; speed: 0.75 mm/s; P: 800 kPa. |

PCL Mw 74,000 Da |

— | Meniscus-like 215 µm 61.5% MESH: printed fibers Ø, 300 µm; space, 200 µm |

- Rabbit BM–MSCs (Passage: 3) | — | — |

Orthotopic implant (rabbits) [±

cells] 24 h static culture before implant End point: 12, 24 weeks - Synovial fluid (analysis of IL-1 and TNF-α) - Implants (gross evaluation, histology for structure, COL, proteoglycans, IHC for COL I/II) - Cartilage (gross evaluation, SEM, histology for structure, COL II, scoring) - Mechanical behavior, tensile test |

| Zhang et al., 25 | 3D CAD meniscus scaffolds FFF 3D printer Parameters. Nozzle Ø: 317, 516, 516 µm; print T:130°C; speed: 0.75, 0.85, 0.6 mm/s; P: 800 kPa. |

PCL Mw 74,600 Da |

— | Meniscus-like 215, 320, 515 µm/ 61.5%, 63.1%, 64.2% MESH: printed fibers Ø, 304, 315, 328 µm; space, 200, 300, 500 µm |

- Rabbit BM-MSCs (Passage: 2–3) | - Surface wettability - Mechanical behavior, tensile/compression |

Static culture

- Cell adhesion, viability and proliferation - DNA content, GAG, COL I/II - Gene expression (fibrochondrogenesis-COL I/ II, aggrecan; osteogenesis-ALP; hypertrophy—COLX) - If for COL I/II deposition -Mechanical behavior, tensile/ compressive/ elastic moduli |

Orthotopic implant (rabbit) [−

cells] End point: 12 weeks - Gross morphology - histology and IHC (proteoglycans, COL I/III, COL II) - Cartilage score (ICRS) |

| Huebner et al., 143 | 3D CAD of scaffolds 3D bioprinter (Bioplotter, EnvisionTEC). Parameters. Nozzle internal Ø: 200 µm; speed: 0.4 mm/s; P: 0.6 N/mm2. |

PCL Mw 43,000 Da |

— | Cylinder, 7.5 × 5 mm 100/400 μm (interstrand space) MESH:32 layers in 0°/90° strand laydown pattern |

— | - Microarchitecture optical characterization | — |

Subcutaneous implant (rat)

End-point: 4, 12 weeks - Histochemical staining (% matrix density, % COL alignment, orientation index) - Mechanical characteristics via AFM |

| Bahcecioglu et al. 144 | 3D Bioprinter (Bioscaffolder system, SYS +

ENG). Parameters. print T: 150°C; strand orientation: 0°–90°; strand distance: 1 mm. |

PCL Mw 50,000 Da |

— | Prism, 4 × 4 × 3 mm 700 μm MESH: 0°–90° strand orientation and 1mm strand distance |

- Pig MFCs (Passage: 2) | - Mechanical behavior, compression - SEM |

Static and dynamic culture

(compression)

- DNA content - Cell viability - Cell metabolic activity - COL content - sGAG content - Histology and IHC (COL I/II) - Mechanical behavior, compression |

— |

| Warren et al., 148 | 3D CAD (Solid Works 2015, Waltham, MA) 3D Bioprinter (Bioplotter, EnvisionTEC). Parameters. Nozzle Ø: 200 µm; print T: 120°C; speed: 0.4 mm/s; P: 0.6 N/mm2. |

PCL Mw 43,600 Da |

Cylinder, 7.5 × 5 mm MESH: 213/222/208 μm strand with and 112/185/408 μm interstrand space |

— | — |

Subcutaneous implant (rats)

End point: 4, 8, 12 weeks - Histology (COL, cell density, %matrix fill and density, quantification of % area with COL fiber alignment, F-actin) |

||

| Luis et al. 151 | 3D CAD meniscus scaffolds Pneumatic extrusion 3D printer. Parameters. Nozzle Ø: 20–21G; T: 40°C–80°C (Nozzle) and 80°C–110°C (Print Bed) |

Ecoflex30 and Ecoflex50 Silicone elastomers | — | Meniscus-like, 4.08 ± 0.14 cm × 2.08 ± 0.19

cm MESH: — |

— | - Surface and cross-sectional morphology - Mechanical behavior, compression |

— | — |

| Luis et al. 152 | 3D CAD Custom pneumatic printer. Parameters. Needle: 21G; speed: 4800 mm/min; flow: 0.5 mL/min. |

Ecoflex30 and Ecoflex50 Silicone elastomers | — | Meniscus-like, 4 × 2 × 1 cm MESH: regular, striated, laminated layer by layer fibrillar appearance |

- L929, fibroblasts (Passage: N.R.) | - Surface characterization by SEM, surface profilometry, absorption test, XPS, FTIR, TGA, DSC, DTG | - Cell viability/cytotoxicity assay - Mechanical behavior, compression |

— |

| Moroni et al. 155 | CT and MRI 3D porcine menisci scaffolds 3D CAD (Rhynoceros®) Extrusion 3D Bioprinter (Bioplotter, EnvisionTEC) Parameters. Needle Ø: 400 µm; T: 190°C; speed: 300 mm/s; P: 5 bar |

PEOT/PBT | — | Meniscus-like (solid or hollow

fibers) 70%–80% MESH: bottom and top, 0°/45°/90°/135° angle deposition architecture; middle part, 0°/90° angle deposition structure |

— | - Mechanical properties, extrinsic stiffness and

equilibrium modulus - Numerical analyses |

— | — |

| Zhu et al. 167 | MR/CT of human knee; Materialize magics 20.03 software (Materialize) Parameters. N.R. |

PCU | — | Anatomical shape of the meniscus 37%; 41%; 45%; 47% MESH: TPMS structures - primitive surface - gyroid surfaces |

— | - Compression stresses, shear stresses, and characteristics of stress concentrated area | — | — |

| Zhu et al. 168 | MR/CT of human knee; Materialize magics 20.03 software (Materialize) Parameters. N.R. |

PCU | — | Anatomical shape of the meniscus Pore size: 800/700/600/ 450/650/550/500/400 μm 63.3%; 53.7%; 44.3%; 34.5%; 56.2%; 56.9%; 57.2% 58.2% MESH: surface layer, lamellar layer, circumferential fibers, and radial fibers |

— | - Mechanical compressive test; SEM | — | — |

| Luis et al. 173 | 3D CAD heat-cured extrusion-based technology. Parameters. Nozzle Ø: 510 µm; T: 60°C (Nozzle) and 100°C (Print Bed); extrusion rate: 0.5 mL/min | Ecoflex30 and Ecoflex50 Silicone elastomers | — | Cube, 2 × 2 × 2 cm; cylinder, 2.8 × 1.3 cm;

meniscus-like, 4 × 2 × 1 cm Ecoflex50: 0.27%–0.13% Ecoflex30: 0.35%–0.18% MESH: — |

- L929, fibroblasts (Passage: N.R.) |

- X-ray CT - Mechanical tests, compression |

- Cytotoxicity assay | — |

AFM: atomic force microscopy; ALP: alkaline phosphatase; BM-MSC: bone marrow mesenchymal stem cells; CAD: computer aided design; CAM: computer aided manufacturing; cm: centimeters; COL: collagen; CTGF: connective tissue growth factor; Da: Dalton; dECM: decellularized extracellular matrix; FFF: fusion filament fabrication; G: gauge; GAG: glycosaminoglycans; GelMA: gelatin methacrylate; HA: hyaluronic acid; hASCs: human adipose derived stem cells; IF: immunofluorescence; IFPSCs: Infrapatellar fat pad stem cells; IHC: immunohistochemistry; IL: interleukin; kPa: kilopascal; MFCs: meniscal fibrochondrocytes; Micro-CT: micro computed tomography; mL/min: milliliters/minute; mm: millimeters; mm/s: millimeters/second; MPa: megapascal; MRI: magnetic resonance imaging; Mw: molecular weight; N.R.: not reported; N/mm: Newton/millimeter; N/mm2: Newton/square millimeter; P: pressure; PCL: ε-polycaprolactone; PCU: polycarbonate urethane; PEOT/PBT: Poly(ethyleneoxideterephthalate)/poly(butyleneterephthalate); PLA: poly lactic acid; PLGA: poly lactic-co-glycolic acid; PU: polyurethane; s: second; SEM: scanning electron microscopy; SOX9: SRY-Box Transcription Factor 9; T: temperature; TGFβ3: transforming growth factor beta 3; TNF-α: tumor necrosis factor-alpha; °C: centigrades; µm: micrometers; Ø: diameter.

Table 2.

Synthetic 3D printed conditioned scaffolds.

| Authors and references | Printing method/parameters | Printing material | Additives or bioink | Shape and/or

dimensions — Pore size µm/porosity% |

Cells | Scaffold characterization studies | In vitro

cells/scaffold interactions |

In vivo studies |

|---|---|---|---|---|---|---|---|---|

| Bahcecioglu et al. 27 | 3D CAD (SketchUp, Google). 3D Bioprinter (Bioscaffolder, SYS + ENG). Parameters. Strand orientation: 0/90°; strand distance: 1 mm; w/wo shifting (offset: 0.5 mm) and w/wo circumferential strands. Pig knee MRI scanned on a 3T scanner; lateral meniscus CAD (Mimics, Materialize); 3D Bioprinter (Bioscaffolder, SYS + ENG). |

PCL Mw 50,000 Da |

- GelMA + cells suspension (impregnation) - GelMA- Agarose + cells suspension (impregnation) |

- Square prism, 10 × 10 × 3 mm; - Rectangular prism, 30 × 10 × 3 mm; - Coliseum, 26 × 8 × 5 mm 810 ± 40 μm MESH: Scaffolds w/wo circumferential strands + non-shifted designs + shifted design |

- Human fibrochondrocytes (Passage: 3) | - SEM - Mechanical behavior, compressive/tensile load |

Static culture

- Cell viability - COL I/II deposition, immunostaining |

— |

| Ghodbane et al. 38 | 3D Bioprinter (Bioplotter, EnvisionTEC). Pneumatic

extrusion. Parameters. Needle inner Ø: 400 µm; print T: 160°C; speed: 1.2 mm/s; P: 8.9 bar. |

p(DTD DD) | Collagen-hyaluronate sponge infusion | Anterior-posterior length: 32 mm; medial-lateral length:

24 mm 69.9% ± 8.0% MESH: successive layers of circumferential and radial filaments |

— | - Determination of percent polymer and

COL-hyaluronan - Porosity - Mechanical behavior, confined compressive creep, circumferential tensile testing - Suture retention test - In situ contact stress test |

— | — |

| Li et al. 140 | 3D CAM/CAD of rabbit medial meniscus (SolidWorks,

Autodesk), 3D-Bioprinter (Bioplotter,

EnvisionTEC). Parameters. Nozzle Ø: 300 µm; T: 130°C; speed: 7.0 mm/s; P: 0.8 MPa. |

PCL Mw 80,000 Da |

SF crosslinking + synovial MSCs specific affinity peptide | - Medial meniscus model of a wedged shaped arc

disk 300 µm MESH: PCL bundles alternately oriented along the circumferential and perpendicular direction in a bionic manner |

- Rat synovial derived MSCs (Passage: 3) | - SEM - Degradation in vitro - Frictional force of interface - Mechanical behavior, compression - FTIR |

Static culture - Cell viability - Cell morphology - Biochemical assays (GAG, COL I/II) - Gene expression (COL I/II, SOX9, aggrecan) - Synovial derived MSCs recruitment in vivo |

Orthotopic implant

(rat) [− cells] Synovial MSCs recruitment (rabbit) [− cells] End point: 12, 24 weeks - Gross evaluation (meniscus) - Cartilage evaluation - SEM (cartilage) - Inflammatory response (histology, IL-1, TNF-α synovia, and synovial fluid) - Biomechanical behavior, compressive/tensile load |

| Bahcecioglu et al. 141 | 3D CAD (SketchUp, Google) 3D Bioprinter (Bioscaffolder system, SYS + ENG). Parameters. Strand orientation: 0/90°; strand distance: 1 mm. |

PCL Mw 70,000–90,000 Da |

- Agarose (impregnation) - GelMA (impregnation) - Agarose + cells suspension (impregnation of inner region) and GelMA + cells suspension (impregnation of outer region) |

- Prism, 4 × 4 × 3 mm - Meniscus-like, outer Ø: 30 mm, height at periphery: 5 mm, inner Ø: 10 mm 751 ± 43 μm (PCL) in xy-direction and 97 ± 40 μm in z-direction, filled with hydrogel MESH: strand distance, 1 mm; strand orientation, 0/90°; average strand Ø, 211 ± 18 μm |

- Pig MFCs (Passage: 2) | - Mechanical behavior, compressive/tensile load |

Static and dynamic culture

(compression)

- Cell viability - Biochemical assays (DNA, sGAGs, hydroxyproline, and COL content) - IF (COL I/II) |

— |

| Cengiz et al. 142 | 3D Bioprinter (Bioplotter,

EnvisionTEC) Parameters. Needle Ø: 22G metallic; print T: 110°C; P: 5.5 bar. |

PCL Mw 45,000 Da |

Entrapped SF (8 or 16 wt%) in PCL | 5 mm3

697.1 µm, 61.1% (PCL); 278.7 µm, 54.6% (PCL + 8%SF); 287.2 µm; 50.0% (PCL + 16%SF) MESH: parallel strands 1.2 mm apart from each other (layers); layer-wise alternating strand directions of 90° and 0° (3D cubic cage) |

- Human meniscocytes (Passage: 5) - Human IFPSCs (Passage: 4) |

- Micro-CT - SEM - Water uptake - Mechanical behavior, compression |

Static culture

- Cell adhesion/migration (SEM) - Cell viability - Proliferation - Staining for filamentous actin |

Subcutaneous implant (nude mice)

[+cells] 7 d static culture before implant End point: 4 weeks - Micro-CT - Histological analyses for tissue infiltration, COL matrix, vessels, inflammation |

| Nakagawa et al. 145 | MRI of ovine meniscus CAD reconstruction of sheep medial meniscus 3D Bioprinter (Bioplotter, Envision TEC), Parameters. T: 120°C; microstrands: 300 µm; microchannels: 100 µm. |

PCL Mw 65,000 Da |

Recombinant human CTGF (outer/middle zones) and recombinant human TGF-β3 (inner/middle zones) incorporation in PLGA | Meniscus-like 100/200 μm MESH: layer path, 300 μm microstrands, 100 μm microchannels |

— | — | — |

Orthotopic implant (sheep)

End-point: 6, 12 months - MRI and MRI score - Macroscopic analysis - Histological analysis of meniscal, articular cartilage, and synovial tissues - Meniscal histological score (size, morphology, integrity, integration to the capsule, cellularity, cell morphology, COL organization, matrix staining) |

| Cengiz et al. 146 | 3D Bioprinter (Bioplotter,

EnvisionTEC). Parameters. Print T: 110°C; P: 5.5 bar. |

PCL Mw 45,000 Da |

SF reinforced in the middle on the transverse plane with PCL | 5 m3

242.1 ± 7.6μm 76.9% ± 0.5% MESH: layer-wise alternating strand directions of 45° and 135°; 2 mm inter-strands distance |

- Human meniscocytes (Passage: 5) - Human ADSCs from IFP (Passage: 4) |

- SEM - Micro-CT - Water uptake - Suture retention test - X-ray diffraction - Mechanical behavior, compression - In vitro enzymatic degradation |

— |

Subcutaneous implant (nude mice)

[± cells] 7 d static culture before implant End point: 4 weeks - Histological analyses for biocompatibility, tissue infiltration, new vessels |

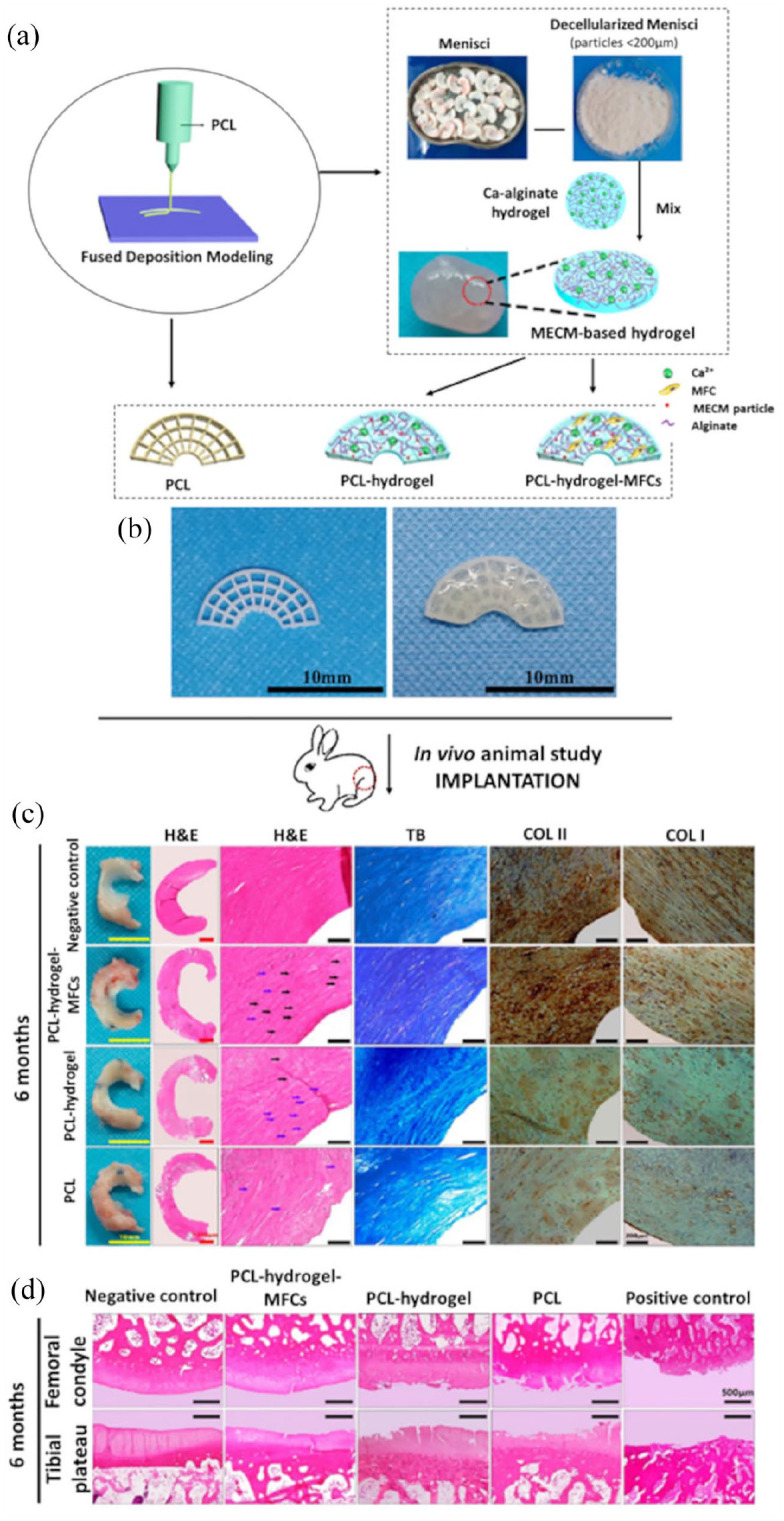

| Chen et al. 147 | Micro-CT of rabbit menisci 3D CAD of scaffolds FFF 3D printing. Parameters. N.R. |

PCL Mw 45,000 Da |

- Pig meniscal dECM injection and crossliking - Pig meniscal dECM injection and crossliking + cells |

- Wedge-shaped porous scaffold, 10 × 4 × 1

mm 1000 μm MESH: circumferential fibers spacing of 1000 μm, adjacent radial fibers angle of 18°, fiber diameters of 250 μm |

- Rabbit MFCs (Passage: 3) | - Water contact angle, - FTIR - SEM - Mechanical behavior, compressive/tensile load |

— |

Subcutaneous implant (rats) [−

cells] End point: 1 week, 1 month - Histology for inflammatory and immune responses Orthotopic implant (rabbit) [± cells] 24 h static culture before implant End point: 3, 6 months - Morphologic observation - Histology (cartilage) - IHC (COL I/II) - Ishida Score menisci - COL and GAG content - Mechanical behavior, compressive/tensile load - Image assessment (X-ray, MRI) - Kellgren−Lawrence and WORMS grading |

| Lee et al. 149 | Laser Scan of human/sheep Meniscus 3D CAD 3D Bioprinter (Bioplotter, EnvisionTEC). Parameters.print T: 120°C. |

PCL Mw 65,000 Da |

Tethering of CTGF and TGF-β3 incorporated in PLGA microstrands | Meniscus-like 100 µm MESH: (a) interlaid strands and interconnecting microchannels with 100 µm Ø + circumferentially aligned fibers added (human meniscus scaffold); (b) 300 µm microstrands and 100 mm microchannels (sheep meniscus scaffold) |

- Human BM or synovium MSCs (Passage: 2–3) | — |

Static culture

- Cell recruitment - Fibrocartilage matrix formation |

Orthotopic implant (sheep) [−

cells] End point: 12 weeks - Mechanical behavior (dynamic compression, pull-out strength, friction coefficient, stress relaxation, tensile test) |

| Abar et al. 150 | 3D CAM/CAD (Fusion 360), FFF 3D printer (Taz 5,

Lulzbot). Parameters. Nozzle Ø: 400 µm; print T: 212°C–220°C; bed T: 40°C; speed: 360 mm/min. |

PCU | Collagen hydrogel infill | Prism, 105 × 55 × 1.66 mm 0/100/200/400/600/800 µm MESH: first layer, a solid printed in diagonal pattern; next four layers, rectilinear infill pattern |

- NIH/3T3, fibroblasts in aqueous or COL solution (Passage: N.R.) | - Light microscopy - Micro-CT - Mechanical behavior, tensile testing |

Static culture

- Cell proliferation and distribution |

— |

| Ghodbane et al. 153 | 3D Bioprinter (Bioplotter,

EnvisionTEC). Pneumatic extrusion. Parameters. Nozzle inner Ø: 500 µm; T: 160 °C; P: 9 bar; speed: 2 and 4.5 mm/s. |

p(DTD DD) | Collagen infusion | Anterior-posterior length: 32 mm, medial-lateral

length: 24 mm 69.9% ± 8.0% MESH: successive layers of circumferential and radial filaments |

— | - Orientation characterization (XRD) - Mechanical behavior, circumferential tensile stiffness and ultimate tensile load |

— | — |

| Ghodbane et al. 154 | 3D Bioprinter (Bioplotter, EnvisionTEC). Pneumatic

extrusion. Parameters. Needle inner Ø: 400 µm; print T: 160°C; speed: 1.2 mm/s; P: 8.9 bar. |

p(DTD DD) | Collagen hyaluronate sponge infusion | Anterior-posterior length: 32 mm, medial-lateral

length: 24 mm 69.9% ± 8.0% MESH: successive layers of circumferential and radial filaments |

— | — | — |

Orthotopic implant (sheep)

End point: 12, 24 weeks Histology for magnitude and type of tissue ingrowth, tissue thickness and integrity, surface features, cell density, vascularization, inflammatory response; IF for COL I/II; quantification of COL and sGAGs; cartilage histological analysis |

| Gupta et al. 156 | 3D CAM/CAD of scaffolds (Fusion 360, Autodesk), FFF 3D

printer (Tarantula 3D

printer). Parameters. print T: 200°C; speed: 20 mm/s. |

PLA | - COL crosslinking - alginate - oxidized alginate Self-healing interpenetrating network hydrogel |

Square prism, 10 × 10 × 3 mm 400 µm MESH: layer by layer with orthogonal orientation of fibers between successive layers. Fiber diameter, 200 μm; fiber spacing in each layer, 400 μm |

- Human UC-MSCs (Passage: N.R.) | - Cytotoxicity - Degree of carboxylation - Mechanical behavior, compression - Contact angle - Characterization of hydrogel impregnated scaffolds (in vitro degradation, swelling ratio) |

Static culture

- Cell viability/ proliferation/ morphology - Differentiation |

Subcutaneous implant (rats) [−

cells] 28 d of static differentiation before implant End point: 14, 28 days - Biocompatibility - Micro-CT - Histology (tissue architecture, COL content, GAG) |

| Yang et al. 224 | 3D printer (Regenovo 3D Bio-Architect

Sparrow). Parameters. Print T: 17°C–22°C; needle inner Ø 260 µm; print bed T: 0°C |

N-acryloylsemicarbazide/gelatin | Polydopamine coated-ZIF-8 | - Printed grid, 66 × 56 × 0.87 mm - Printed porous cuboid, 40 × 20 × 2.1 mm _______________________ MESH: 6 layers grid |

- L929 mouse fibroblasts - Rabbit MFCs (Passage: 3) |

- Mechanical characterization, tensile/compressive wear,

resistance against femur, tearing tests, suture

strength - Swelling behavior - Biocompatibility |

- In vitro antibacterial activity (Staphylococcus aureus and Escherichia coli) | — |

ADSCs: adipose-derived stem cells; BM: bone marrow; CAD: computer aided design; CAM: computer aided manufacturing; CO: collagen; CTGF: connective tissue growth factor; Da: Dalton; dECM: decellularized extracellular matrix; FFF: fusion filament fabrication; FTIR: Fourier-transform infrared spectroscopy; G: gauge; GAG: glycosaminoglycans; GelMA: gelatin methacrylate; IF: immunofluorescence; IFP: infrapatellar fat pad; IL: interleukin; IFPSCs: infrapatellar fat pad stem cells; IHC: immunohistochemistry; MFCs: meniscal fibrochondrocytes; Micro-CT: micro computed tomography; mm: millimiters; mm/min: millimeters/minute; mm/s: millimeters/second; MPa: megapascal; MRI: magnetic resonance imaging; MSC: mesenchymal stem cells; Mw: molecular weight; N.R.: not reported; p(DTD DD): poly(desaminotyrosyl-tyrosine dodecyl ester dodecanoate); P: pressure; PCL: ε-polycaprolactone; PCU: polycarbonate urethane; PLGA: poly lactic-co-glycolic acid; PU: polyurethane; SEM: scanning electron microscopy; SF: silk fibroin; sGAG: sulfated glycosaminoglycans; SOX9: SRY-Box transcription factor 9; T: temperature; TGFβ3: transforming growth factor, beta 3; UC: umbilical cord; w/wo: with/without; wt: weight; XRD: X-ray diffraction analysis; µm: micrometers; °C: centigrades; Ø: diameter.

Pus

PUs are elastomers made through polyaddition of three basic components: diisocyanate, oligodiol (i.e. macrodiol or polyol), and a chain extender (diol or diamine).160,163 Specifically, the isocyanate can either be aromatic (higher reactivity and better mechanical properties) or aliphatic (less toxic and more stable to light). Kim et al. 164 described the use thermoplastic PU for fabrication of a 3D printed implantable drug delivery device. As for the oligodiols, these include polyether, polyester, or polycarbonate (PC). PC-based PUs (i.e. PCU) are more durable, with good mechanical properties, hydrolytic resistance, and low friction properties.165,166 Zhu et al.,167,168 focused on design and biomechanical characterization of PCU-based porous meniscal structures fabricated using triply periodic minimal surfaces (TPMS). Precise control over structure configuration seems to be beneficial to adjust mechanical stiffness of the meniscal implant.

To obtain polymers with intermediate characteristics, they can be blended or copolymerized.159,169,170 In meniscus 3D printing, the rate of hydrolysis of PCL has been adjusted through a blend with medical grade PU that is Carbothane PC-3575A (Lubrizol, USA), 132 widely investigated for the fabrication of long-term implants. For PU/PCL blends the phase transition temperature decreases as PU content increases. 171

Through a fused filament fabrication (FFF) approach, Abar et al. 150 prepared different PCU prism-shaped scaffolds characterized by a varying in plane pore-size (i.e. 0/100/200/400/600/800 µm). To do that, the noozle temperature ranged from 220°C to 212°C, progressively. The temperature of the print bed was set at 40°C and printing occurred at a speed of 360mm/min using a nozzle with a 0.4 mm inner diameter.

Silicone elastomers

Silicone elastomers Ecoflex (Smooth-On Inc., Macungie, PA, USA) are aliphatic–aromatic co-polyesters. They display an excellent flexibility and relatively fast degradation, without significant toxicological effects. Scant data are reported for their use in biomedicine. 172

Ecoflex 30 and Ecoflex 50 use in 3D printing of prosthesis is recent: Luis et al.151,152,173 fabricated cube/cylinder-like and/or meniscus-like structures through a pneumatic extrusion 3D printer; the experimental setup described by the Authors used nozzles with a diameter of 20–21G/0.51 mm and a T of the nozzle and of the print bed in the range of 60°C–80°C and 80°C–110°C, respectively.152,173 The average porosity achieved was that of 0.27%–0.13% (Ecoflex 50) and 0.35%–0.18% (Ecoflex 30) suggesting the fabrication of high-density 3D-printed silicone scaffolds. 173

p(DTD DD)

Poly(desaminotyrosyl-tyrosine dodecyl ester dodecanoate) (p(DTD DD)) belongs to tyrosine-derived polyarylates developed in the 2003 by Bourke and Kohn. 174 Considering the mechanical properties required to a meniscal scaffold, p(DTD DD) shows the most interesting potential among the polyarylates. Degradation does not produce toxic molecules. 175

As for meniscal scaffolds development, Ghodbane et al.38,153,154 fabricated p(DTD DD) printed devices through a pneumatic extrusion approach. Specifically, p(DTD DD) was printed at 160°C at 1.2–4.5 mm/s at a pressure of 8.9–9 bar using 0.4–0.5 mm inner diameter needle; the porosity achieved was of 69.9% ± 8.0%.

PEOT/PBT

Poly(ethylene oxide-terephthalate)-co-poly(butylene terephthalate) (PEOT/PBT) are thermoplastic elastomers made of a soft segment (i.e. PEOT) and a hard segment (i.e. PBT). Varying the copolymer composition, the PEOT/PBT physical properties can be broadly tuned. The PBT melting temperature increases both with increasing PBT content and with increasing PEOT block length in the copolymer.176,177 Also, mechanical and swelling behaviors can change according to the composition of PEOT/ PBT copolymers showing variations in tensile strengths from 8 to 23 MPa and in elongations at break from 500% to 1300%. 178 As for degradation, it can occur through hydrolysis and oxidation (in vivo ascribable to macrophages) and can be relatively slow. Long-term effects of degradation in the body are not well known. 179

PEOT/PBT meniscus-like scaffolds were prepared by Moroni et al. 155 ; the polymer, placed in a syringe and heated at 190 °C, was extruded at a speed of 300 mm/s (pressure, 5 bar) through a needle with a diameter of 400 µm. The described system set up allowed for fabrication of scaffolds with a 70%–80% porosity, achieved by the fine plotting the of the fibers orientation.

PLA