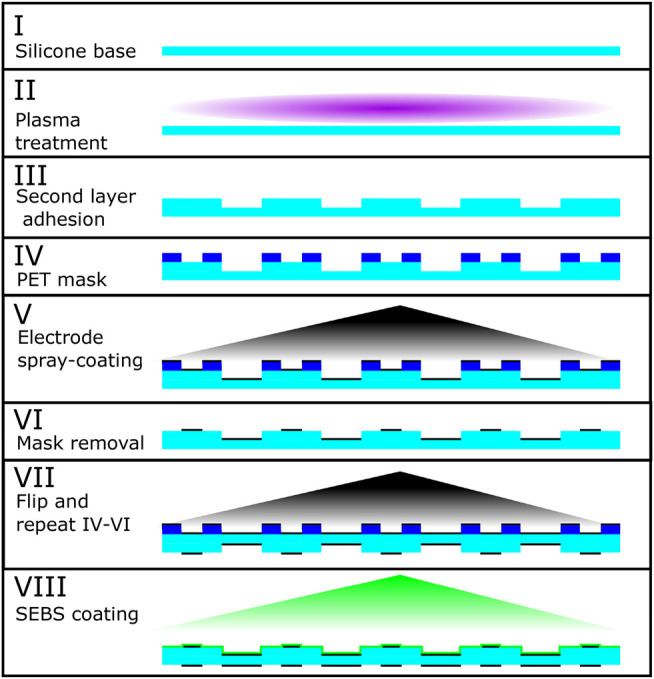

FIGURE 8.

Production of the PILA actuator. Starting at stage I with the silicone base layer (Wacker Elastosil®2030), this is plasma treated (II) to activate the surface for bonding with a similarly tre’ated second layer to produce the different thickness sections (III). A PET mask is used (IV) to selectively spray-coat the conductive electrode mixture onto the active areas (V). This process is then repeated on the other side for the ground electrodes (VII). Finally a thin layer of SEBS-g-MA (maleic anhydride grafted styrene-ethylene-butylene-styrene) co-block polymer is applied to reduce gas permeability.