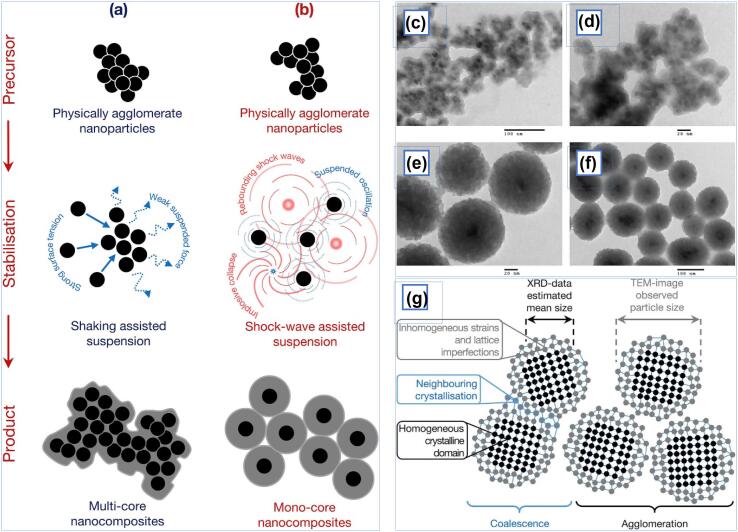

Fig. 3.

Formation illustration of Fe3O4 nanocomposites via (a) shaking assisted process and (b) US irradiation. TEM images of (c,d) multi-core nanocomposites show the composite having a polycrystalline core while (e,f) nanocomposites produced from US assistance exhibit clear mono core–shell structure, attributed to the diffusive and surface-protective shockwaves from implosive bubble collapse that form discrete core Fe3O4 NPs within silica. (g) In the US-assisted preparation of MNPs, it has been hypothesised that the shock waves generated from the collapse of the acoustic bubble counteract the high tension of MNPs, thus preventing crystalline coalescence on neighbouring surfaces that would yield heterogeneous-sized products. Reprinted from [97] with permission from Elsevier (CC-BY license).