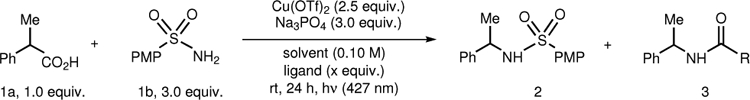

Table 1 |.

Optimization studies of decarboxylative sulfonamidation.

| ||||

|---|---|---|---|---|

| entry | solvent | ligand | 2 (%) | 3 (%) |

| 1 | THF, Et2O, EtOAc, toluene, CH2Cl2, DMF | - | < 2 | |

| 2 | CH2Cl2 | PPh3, DABCO, pyridine dtbbpy (0.20 equiv) | < 5 | < 5 |

| 3 | CH2Cl2 | dtbbpy (2.0 equiv.) | 6 | 4 |

| 4 | CH2Cl2 | MeCN (2.0 equiv.) | 18 | 5 |

| 5 | CH2Cl2 | MeCN (5.0 equiv.) | 25 | 43 |

| 6 | CH2Cl2 | EtCN (5.0 equiv.) | 40 | 0 |

| 7 | CH2Cl2 | PhCN (5.0 equiv.) | 26 | 0 |

| 8 | CH2Cl2 | CyCN (5.0 equiv.) | 34 | 0 |

| 9 | CH2Cl2 | i-PrCN (5.0 equiv.) | 58 | 0 |

| 10 | CH2Cl2 | i-PrCN (5.5 equiv.) | 59 | 2 |

| 11 | CH2Cl2 | i-PrCN (5.5 equiv.) | 66(73a) | 0 |

| 12b | CH2Cl2 | i-PrCN (5.5 equiv.) | 0 | 0 |

| 13c | CH2Cl2 | i-PrCN (5.5 equiv.) | 58 | 6 |

0.10 mmol screening conditions: Cu(OTf)2 (2.5 equiv.), Na3PO4 (3.0 equiv.), 1a (1.0 equiv.), 1b (3.0 equiv.), ligand, and solvent (0.10 M) are added to a 1-dram reaction vial equipped with a stir bar in a glovebox. The vial is stirred at rt with irradiation by a 34 W blue LED. In situ yield determined by GC or 1H NMR with 1-methylnaphthalene as an internal standard.

Isolated yield on 0.20 mmol scale.

Reaction conducted without light.

Reaction set up under air using unpurified solvent.