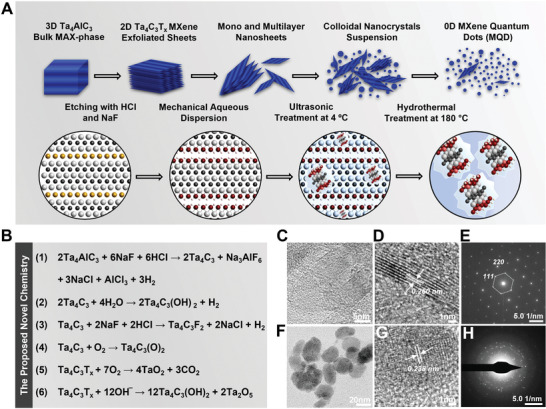

Figure 1.

Synthesis schematic model, stoichiometry, and materials characterization. A) Step‐by‐step schematic on the conversation of Ta4AlC3 MAX phase bulk to 0D Ta4C3T x MQDs using a facile protocol. Briefly, Ta4AlC3 MAX phase powder was etched using an HCl/NaF etchant to remove Al layers and synthesize Ta4C3T x MXene nanosheets. This wet etching was performed continuously during the synthesis process for 48 h. Simultaneously, heating at 60 °C enhanced the exfoliation and functionalization of Ta4AlC3 to form accordion‐like 2D MXene. The exfoliated Ta4C3T x nanosheets were further treated by sonication and mechanical vibration to obtain multi‐, oligo‐, and monolayer flakes, which were subsequently treated using a hydrothermal process to form Ta4C3T x MQDs with concentrated functional groups as well as stable surface tantalum oxides. B) Proposed reaction chemistry for the synthesis of Ta4C3T x MQDs, including surface modification with tantalum oxides (TaO2 and Ta2O5). C–H) Morphology and microstructural characterization of the Ta4C3T x MNSs and MQDs. C,D) High‐resolution TEM (HRTEM) images of multilayer Ta4C3T x nanosheets revealed well‐defined and exfoliated crystals with lattice d‐spacing of ≈0.260 nm. E) Furthermore, the corresponding SAED pattern of the nanosheets depicted a uniform hexagonal crystallization pattern typical for MXene materials. F) HRTEM images of Ta4C3T x MQDs displayed proper synthesis of particles with high surface functionalization after hydrothermal treatment at 180 °C. G) As shown, the average diameter of a single Ta4C3T x particle is ≈3.5 nm, which is ideal for targeted subcellular applications. H) The lattice d‐spacing of MQDs was found to be ≈0.338 nm. Collectively, these data support the successful design and production of the new Ta4C3T x MQDs.