Abstract

Objective:

To investigate the effects of orthodontic mini-implant (OMI) shape and angled-predrilling depth on the mechanical properties of OMIs during the angled insertion procedure.

Materials and Methods:

A total of 30 OMIs (self-drilling type, 7 mm in length) were allocated into six groups according to the OMI shape (cylindrical or tapered) and angled-predrilling depth (control, 1.5-mm and 4.0-mm angled-predrilling; predrilled with 1-mm–diameter drill-bit), as follows: C-con, C-1.5, C-4.0, T-con, T-1.5, and T-4.0 groups (N = 5 per group). The OMIs were installed at an angle of 60° in double-layer artificial bone blocks that simulated the cortical and cancellous bone (Sawbone®). Total insertion time (TIT), maximum insertion torque (MIT), total insertion energy (TIE), and inclination of the time-torque graph (INC) were measured.

Results:

Within the same shape group, angled-predrilling had a shorter TIT than did the control (control vs 1.5; control vs 4.0; all P < .05). MIT and TIE decreased in the order of control, 1.5-mm, and 4.0-mm angled-predrilling (control vs 1.5; 1.5 vs 4.0; all P < .05), but INC increased from control to 1.5-mm angled-predrilling and decreased from 1.5-mm to 4.0-mm angled-predrilling within the same shape group (control vs 1.5, 1.5 vs 4.0; all P < .05). The MIT of the tapered group was greater than that of the cylindrical group (C-con vs T-con, C-1.5 vs T-1.5; all P < .05, C-4.0 vs T-4.0; P < .01). In the same angled-predrilling depth, no differences were observed in TIE between the cylindrical and tapered groups (C-1.5 vs T-1.5, C-4.0 vs T-4.0; all P > .05).

Conclusions:

In angled-predrilling insertion of OMIs into thick cortical bone, tapered OMIs might be a better choice than cylindrical OMIs for increasing primary stability because of higher MIT and similar TIE values.

Keywords: Mechanical properties, Orthodontic mini-implants, Angled-predrilling depth, Mini-implant shape, Angled insertion

INTRODUCTION

Numerous studies1–4 have reported that the higher failure rate of orthodontic mini-implants (OMIs) is related to the mandible rather than the maxilla. When the OMIs are installed into the thick cortical bone in the buccal-attached gingiva of the mandibular posterior area, excessive compression stress, microdamage, and peri-implant bone resorption may be produced as a result.5,6 To overcome these problems, the insertion torque must be brought within the proper range to simultaneously satisfy the primary and secondary stability requirements for OMIs.7–9 Therefore, implant site preparation, such as predrilling, can be regarded as an effective method with which to prevent extreme insertion torque and the consequent risk of OMI fracture.10,11

In clinical situations, OMIs cannot be always installed perpendicular to the bone surface, especially in the buccal-attached gingiva of the mandibular posterior area. Poggio et al.12 claimed that OMIs should be implanted 30° to 40° in relation to the long axis of the tooth in order to allow for the insertion of a longer screw into the available bone depth. Wilmes et al.13 insisted that a 60° to 70° insertion angle to the bone surface is advisable to obtain better bone-to-OMI contact and primary stability. Lim et al.14 also suggested that if the available space between the two adjacent roots is small, a more oblique direction of insertion seems to be favorable in minimizing the risk of root contact. Since most of the in vitro tests have installed OMIs perpendicular to the artificial bone surface,11,15–17 it is necessary to investigate the effects of angled insertion on the mechanical properties of OMIs.

In the in vitro studies, it is important to use double-layer artificial bone blocks, the thickness and mechanical properties of which are similar to those of the cortical and cancellous bone in humans.11,18 If a double-layer artificial bone block with different thickness and mechanical properties than those of the bone in humans is used, improper interpretation of the mechanical results could potentially occur.

Only a few studies10,13,19 have simultaneously investigated the effects of OMI shape and angled-predrilling depth on the mechanical properties of OMIs during the angled insertion procedure. Therefore, the purpose of this study was to investigate the effects of OMI shape and angled-predrilling depth on the mechanical properties of OMIs during the angled insertion procedure in double-layer artificial bone blocks that simulate the cortical and cancellous bone in humans.

MATERIALS AND METHODS

OMIs and Groups

A total of 30 OMIs (self-drilling type, 7 mm in length; Biomaterials Korea Inc, Seoul, Korea) were allocated into six groups according to the OMI shape (cylindrical or tapered; Figure 1A) and angled-predrilling depth (control, 1.5-mm angled-predrilling, and 4.0-mm angled-predrilling), as follows: C-con, C-1.5, C-4.0, T-con, T-1.5, and T-4.0 groups (N = 5 per group). The cylindrical OMIs had an internal diameter of 1.0 mm and an external diameter of 1.45 mm. The tapered OMIs consisted of two parts. The configuration of the lower 4 mm was identical to that of the cylindrical OMI, while the upper 2 mm had an increased taper from 1.0 mm to 1.49 mm for the internal diameter and from 1.45 mm to 1.8 mm for the external diameter.

Figure 1.

(A) Schematic diagram of the orthodontic mini-implants (OMIs, cylindrical shape, OAS-T1507; tapered shape, OAS-T1507T; Biomaterials Korea Inc, Seoul, Korea). (B) Custom-made, double-layer artificial bone blocks made of polyurethane foam simulating the cortical and cancellous bone (Sawbone®, Pacific Research Laboratories Inc, Vashon, Wash). (C) Artificial bone block fixed to the acrylic plate angled at 60° and reinforced with putty. (D) The driving torque tester (Biomaterials Korea).

Artificial Bone Block and Preparation for Angled Installation of OMIs

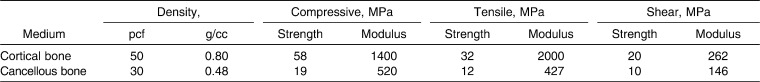

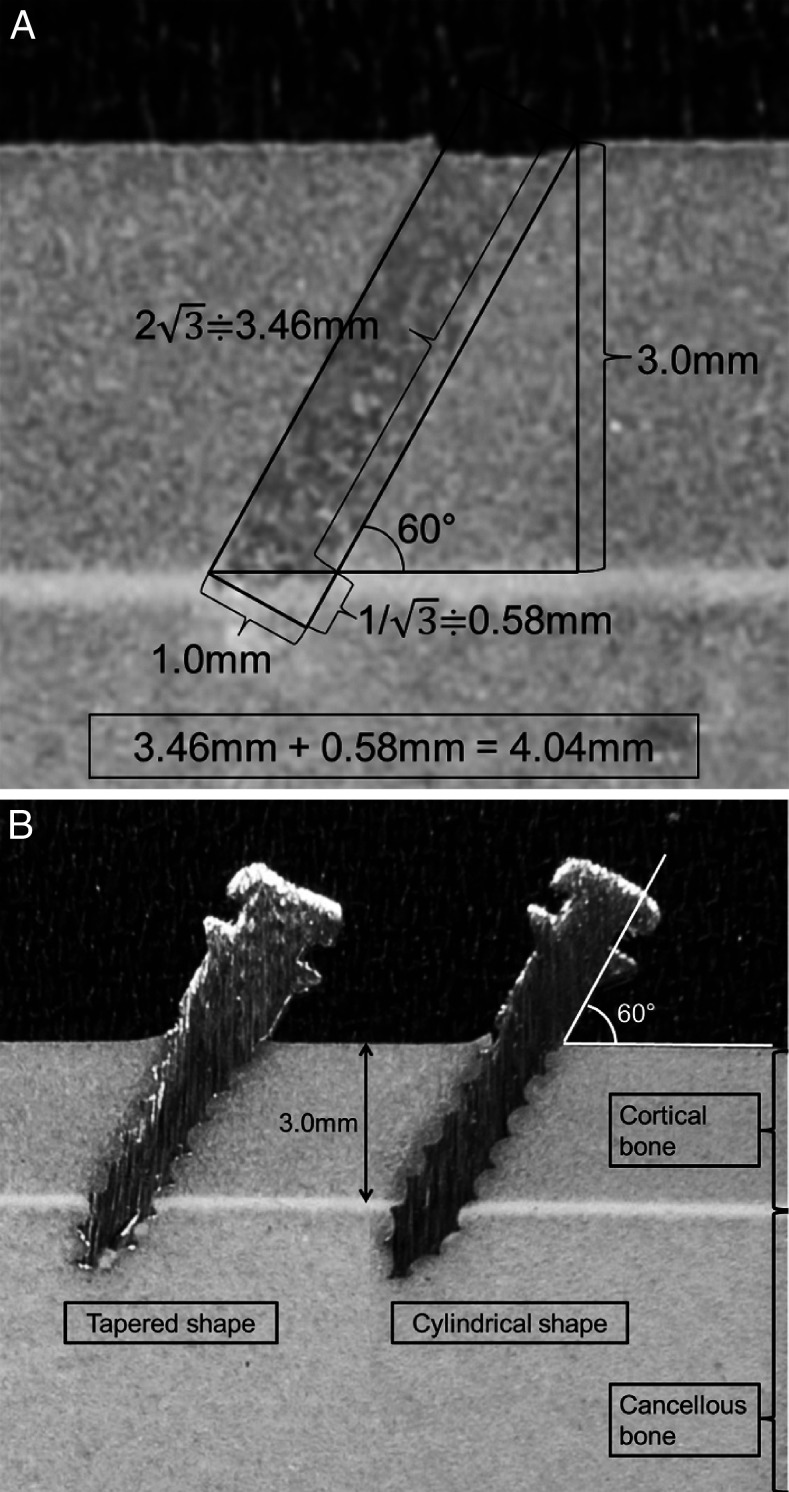

Custom-made, double-layer artificial bone blocks (polyurethane foam, 180 mm long, 15 mm wide, and 18 mm high; Sawbone®, Pacific Research Laboratories Inc, Vashon, Wash; Table 1; Figure 1B) were used to simulate the cortical and cancellous bone.11 The upper layer had a density of 0.80 g/cc (50 pcf) and a height of 3 mm, and the lower layer had a density of 0.48 g/cc (30 pcf) and a height of 15 mm. The reason that the height of the upper layer of the artificial bone block was set at 3.0 mm is that the buccal cortical bone thickness in the mandibular posterior area ranges from 1.50 mm to 3.65 mm, according to Lim et al.14 and Baumgaertel and Hans.20

Table 1.

Mechanical Properties of the Polyurethane Foam (Sawbones®, Pacific Research Laboratories Inc, Vashon, Wash) Used in the Artificial Bone Blocks

To produce the 60° angled insertion, a stand was fabricated with an acryl plate using a CAD program and a laser cutting machine (Figure 1C). After the artificial bone block was attached to the stand using cyanoacrylate glue and reinforced by putty, it was fixed with a metal clamp.

Angled-Predrilling and OMI Installation

The OMIs were installed in the artificial bone blocks using a driving torque tester (Biomaterials Korea Inc; Figure 1D). The tester was set to a uniform speed of 3 rpm, which corresponds to American Society for Testing and Materials regulation F543-02. A 500-g weight was added on the tester's rotational axis to mimic the force applied in a clinical situation.

After a drill-bit (1.0 mm in diameter; Jeil Medical Corp, Seoul, Korea) was attached to the chuck of the torque tester's rotational axis, the angled-predrilling depth (1.5 mm or 4.0 mm) (Figure 2) was set using a digital vernier caliper (Mitutoyo Corp, Tokyo, Japan). When the angled-predrilling was completed, the drill-bit was replaced with an OMI. Each OMI from the six groups was randomly installed with a space of 10 mm.

Figure 2.

(A) Diagram illustrating the 4.0-mm angled-predrilling depth used to predrill the cortical bone completely at a 60° angle of insertion. (B) Cross-sectional view of the tapered and cylindrical OMI inserted at a 60° angle.

The OMIs used in this study consisted of a threaded portion (bottom 6 mm) and a nonthreaded portion (top 1 mm) (Figure 1A). In order to prevent overinsertion of the OMIs, only the threaded portion was inserted into the artificial bone block using a 1-mm–diameter metal bar stop.

Measurements and Statistical Analysis of the Insertion Variables

The insertion variables were total insertion time (TIT), maximum insertion torque (MIT), total insertion energy (TIE), and inclination of the time-torque graph (INC). The definitions for these variables are given in Figure 3. The Kruskal-Wallis test and Mann-Whitney U-test with a Bonferroni correction were performed for statistical analysis.

Figure 3.

Definitions of the insertion variables. Total insertion time (seconds) is the time from the beginning to the end of OMI insertion. Maximum insertion torque (Ncm) is the maximum torque value during OMI insertion. Total insertion energy (J) is calculated by the area under the curve from the beginning to the end of OMI insertion. Inclination ([Ncm/second] × 100) is calculated from the zero point of the torque value to the start of the plateau in the graph.

RESULTS

Total Insertion Time (Tables 2 and 3; Figure 4)

Table 2.

Comparison of the Mechanical Properties During the Insertion of the Cylindrical and Tapered Mini-Implants in the Artificial Bone Blocks in the Control and 1.5-mm and 4.0-mm Angled-Predrilling Groupsa

Table 3.

Comparison of the Mechanical Properties During the Insertion of the Mini-Implants in the Artificial Bone Blocks Among the Cylindrical Shape Groups, Among the Tapered Shape Groups, and Among All Groupsa

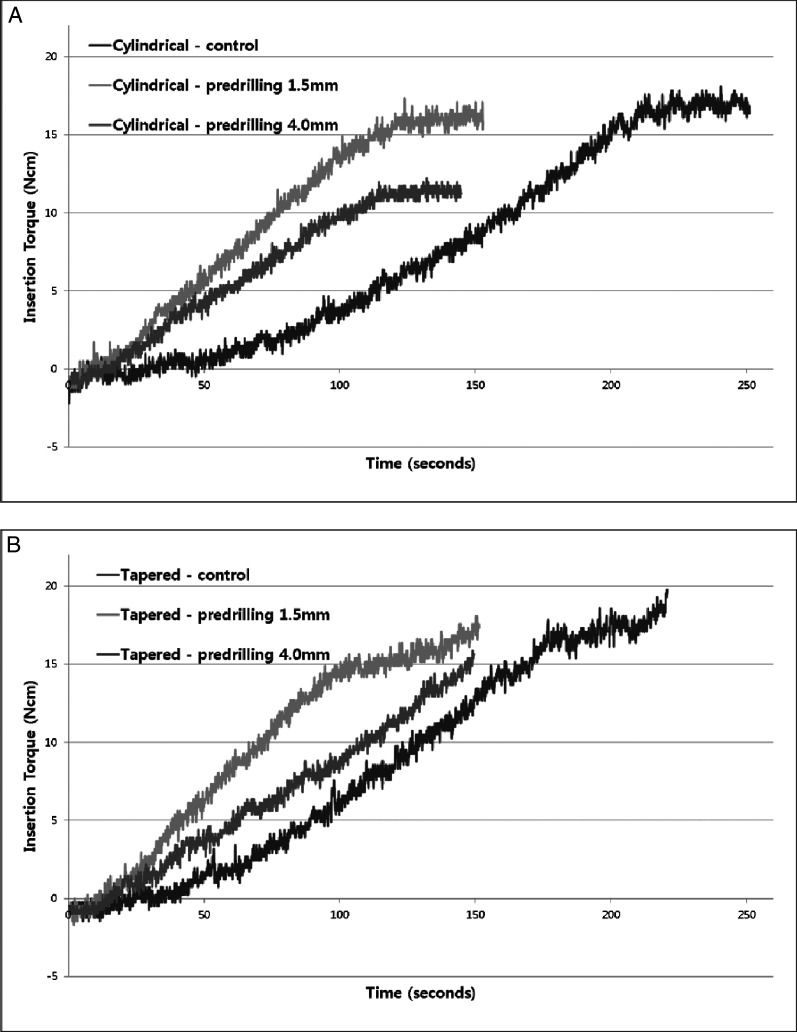

Figure 4.

Superimposition of the time-insertion torque graphs between the control and 1.5-mm and 4.0-mm angled-predrilling groups. (A) Cylindrical OMIs; (B) Tapered OMIs.

Although the TIT of C-con was longer than that of T-con (P < .01, difference of 25.4 seconds), the difference in the number of turns for OMI installation (1.3 turns) did not seem to be critical, since one turn (360°) was completed in 20 seconds (at a speed of 3 rpm). In addition, there was no difference in TIT between the cylindrical and tapered groups within the same angled-predrilling depth (C-1.5 vs T-1.5 and C-4.0 vs T-4.0; all P > .05).

Within the same shape group, the control groups exhibited a longer TIT and more rotation than did the angled-predrilling groups (difference between C-con and C-1.5, 1585.8° and 4.4 turns; difference between C-con and C-4.0, 1785.6° and 5.0 turns; difference between T-con and T-1.5, 1233° and 3.4 turns; and difference between T-con and T-4.0, 1309.7° and 3.6 turns, all P < .0166 with Bonferroni correction). In addition, there was no difference in TIT between the 1.5-mm angled-predrilling and 4.0-mm angled-predrilling depth within the same shape group (C-1.5 vs C-4.0 and T-1.5 vs T-4.0; all P > .0166 with Bonferroni correction).

Maximum Insertion Torque (Tables 2 and 3; Figure 4)

Within the same angled-predrilling depth group, the MIT of the tapered groups was larger than that of the cylindrical groups (C-con vs T-con and C-1.5 vs T-1.5; all P < .05, C-4.0 vs T-4.0; P < .01). Within the same shape group, MIT decreased in the following order: control, 1.5-mm angled-predrilling, and 4.0-mm angled-predrilling (C-con vs C-1.5, C-1.5 vs C-4.0, C-con vs C-4.0, T-1.5 vs T-4.0, and T-con vs T-4.0; all P < .0166 with Bonferroni correction). However, the difference in MIT between T-con and T-1.5 was marginally significant (P = .0167 with Bonferroni correction).

Total Insertion Energy (Tables 2 and 3; Figure 4)

Within the same angled-predrilling depth group, there was no difference in TIE between the cylindrical and tapered groups (C-con vs T-con, C-1.5 vs T-1.5, and C-4.0 vs T-4.0; all P > .05). Within the same shape groups, TIE decreased in the following order: control, 1.5-mm angled-predrilling, and 4.0-mm angled-predrilling (C-con vs C-1.5, C-1.5 vs C-4.0, C-con vs C-4.0, T-con vs T-1.5, T-1.5 vs T-4.0, and T-con vs T-4.0; all P < .0166 with Bonferroni correction).

Inclination of the Time-Torque Graph (Tables 2 and 3; Figure 4)

Although the INC of T-con was steeper than that of C-con (11.8 vs 10.1; P < .01), there was no difference in INC between the cylindrical and tapered groups with the same angled-predrilling depth (C-1.5 vs T-1.5 and C-4.0 vs T-4.0; all P > .05). Regardless of shape, the values of INC increased from control to 1.5-mm angled-predrilling and decreased from 1.5-mm angled-predrilling to 4.0-mm angled-predrilling (C-con vs C-1.5, C-1.5 vs C-4.0, T-con vs T-1.5, and T-1.5 vs T-4.0; all P < .0166 with Bonferroni correction).

DISCUSSION

The finding that a longer TIT and more rotation were required for the control groups than for the angled-predrilling groups within the same shape group (Tables 2 and 3) was consistent with the results reported by Cho and Baek.11 This implies that in cases of angled insertion, some time was required to create a hole in the cortical bone during the first part of OMI installation in the control groups and that slippage of the OMIs might have occurred upon first contact with the bone.11,13 Since the cutting flute of the OMIs could be completely fitted into the predrilling hole after its formation, no time was wasted in making a hole, and no slippage in the cortical bone occurred in the angled-predrilling groups, regardless of the angled-predrilling depth.11 The constant installation speed of the driving torque tester (3 rpm) also seemed to be a reason for the lack of a significant difference in TIT between the 1.5-mm and 4.0-mm angled-predrilling groups (C-1.5 vs C-4.0 and T-1.5 vs T-4.0; all P > .05; Table 3).

The fact that the MIT of the tapered groups was larger than that of the cylindrical groups in the same angled-predrilling depth was in accordance with findings of previous studies.10,11,15,21–24 In the cylindrical group, as the thread with a constant diameter followed the path formed by a previous thread, the torque value steadily increased and reached a final plateau in the time-torque graph (Figure 4). In the tapered group, as the diameter of the OMIs increased from 1.45 mm to 1.8 mm in the upper 2 mm of total length, additional lateral compression force was exerted onto the surface of the cortical bone. This appeared as a final additional increase in torque value following a short plateau in the time-torque graph (Figure 4). These findings are also consistent with those reported by Cho and Baek.11

As the angled-predrilling depth increased from 1.5 mm to 4.0 mm, the cylindrical group exhibited a greater decrease in MIT value, when compared to the control group, than did the tapered group (0.7 Ncm [3.8%] vs 1.1 Ncm [5.7%] in the 1.5-mm angled-predrilling group; 6.1 Ncm [33.1%] vs 4.2 Ncm 21.6%] in the 4.0-mm angled-predrilling group; Table 2). Since the diameter of the drill-bit (1.0 mm) was the same as the core (internal) diameter of the cylindrical OMIs, only the thread portion of the OMIs was embedded in the predrilled part of the cortical bone. Therefore, the MIT decreased rapidly with increasing angled-predrilling depth in the cylindrical group. In the tapered group, the additional tapered portion of the OMIs resulted in a smaller decrease in torque than in the cylindrical group. These trends were identical to the results of Cho and Baek.11

The increase in INC from the control group to the 1.5-mm angled-predrilling group (C-con vs C-1.5 and T-con vs T-1.5; all P < .05; Table 3) can be explained by the shortening of the TIT (C-con vs C-1.5, 245.6 seconds to 157.5 seconds; and T-con vs T-1.5, 220.3 seconds to 151.8 seconds; all P < .05; Tables 2 and 3). Moreover, the decrease in INC from the 1.5-mm angled-predrilling group to the 4.0-mm angled-predrilling group (C-1.5 vs C-4.0 and T-1.5 vs T-4.0; all P < .05; Table 3) may have resulted from a decrease in the insertion torque (C-1.5 vs C-4.0, 17.7 Ncm to 12.3 Ncm; and T-1.5 vs T-4.0, 18.4 Ncm to 15.3 Ncm; all P < .05; Tables 2 and 3). These findings imply that the 1.5-mm angled-predrilling group reached the MIT faster than did the other groups and are in accordance with those of Cho and Baek.11

There was no significant difference in TIE between the cylindrical and tapered groups for the same angled-predrilling depth (C-con vs T-con, C-1.5 vs T-1.5, and C-4.0 vs T-4.0; all P > .05; Table 2). As mentioned above, the tapered group exhibited a final additional increase in torque on the time-torque graph. However, an increase in area due to the final additional increase in torque did not have a significant effect on the total area under the time-torque curve, which represented TIE.

Within the same shape groups, TIE decreased in the order of control, 1.5-mm angled-predrilling, and 4.0-mm angled-predrilling. For the cylindrical group, the TIE value decreased 9.3 J (16.4%) in the 1.5-mm angled-predrilling group and 27.9 J (49.3%) in the 4.0-mm angled-predrilling group when compared to the control group. For the tapered group, the TIE value decreased 7.8 J (14.4%) in the 1.5-mm angled-predrilling group and 24.8 J (45.6%) in the 4.0-mm angled-predrilling group when compared to the control group. In other words, the complete penetration of the cortical bone reduced the TIE value by nearly half.

Both MIT and TIE could be reasonable indicators for predicting the stability of OMIs.23 Since tapered OMIs exhibited a significantly higher MIT value (12.30 Ncm vs 15.28 Ncm; P < .01; Table 2) but a similar TIE value (28.8 J vs 29.6 J; Table 2) compared to the cylindrical OMI at the 4.0-mm angled-predrilling depth, tapered OMIs might be a better choice than cylindrical OMIs for increasing primary stability.

Since this experiment was an in vitro study in artificial bone blocks, the changes in the values of the insertion variables might not be representative of in vivo results and could not be used as real indicators for determining the long-term clinical success rate of OMIs. Further in vivo studies conducted via animal testing and clinical research are necessary to determine the effects of angled-predrilling on MIT, TIE, bone-implant contact, microdamage, and the primary and secondary stability of OMIs.

CONCLUSION

In angled-predrilling insertion of OMIs into thick cortical bone, tapered OMIs might be a better choice than cylindrical OMIs for increasing primary stability as a result of higher MIT and similar TIE values.

REFERENCES

- 1.Cheng S. J, Tseng I. Y, Lee J. J, Kok S. H. A prospective study of the risk factors associated with failure of mini-implants used for orthodontic anchorage. Int J Oral Maxillofac Implants. 2004;19:100–106. [PubMed] [Google Scholar]

- 2.Park H. S, Jeong S. H, Kwon O. W. Factors affecting the clinical success of screw implants used as orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2006;130:18–25. doi: 10.1016/j.ajodo.2004.11.032. [DOI] [PubMed] [Google Scholar]

- 3.Wiechmann D, Meyer U, Büchter A. Success rate of mini- and micro-implants used for orthodontic anchorage: a prospective clinical study. Clin Oral Implants Res. 2007;18:263–267. doi: 10.1111/j.1600-0501.2006.01325.x. [DOI] [PubMed] [Google Scholar]

- 4.Moon C. H, Lee D. G, Lee H. S, Im J. S, Baek S. H. Factors associated with the success rate of orthodontic miniscrews placed in the upper and lower posterior buccal region. Angle Orthod. 2008;78:101–106. doi: 10.2319/121706-515.1. [DOI] [PubMed] [Google Scholar]

- 5.Wawrzinek C, Sommer T, Fischer-Brandies H. Microdamage in cortical bone due to the overtightening of orthodontic microscrews. J Orofac Orthop. 2008;69:121–134. doi: 10.1007/s00056-008-0742-5. [DOI] [PubMed] [Google Scholar]

- 6.Lee N. K, Baek S. H. Effects of the diameter and shape of orthodontic mini-implants on microdamage to the cortical bone. Am J Orthod Dentofacial Orthop. 2010;138:8.e1–8.e8. doi: 10.1016/j.ajodo.2010.02.019. [DOI] [PubMed] [Google Scholar]

- 7.Motoyoshi M, Hirabayashi M, Uemura M, Shimizu N. Recommended placement torque when tightening an orthodontic mini-implant. Clin Oral Implants Res. 2006;17:109–114. doi: 10.1111/j.1600-0501.2005.01211.x. [DOI] [PubMed] [Google Scholar]

- 8.Motoyoshi M, Yoshida T, Ono A, Shimizu N. Effect of cortical bone thickness and implant placement torque on stability of orthodontic mini-implants. Int J Oral Maxillofac Implants. 2007;22:779–784. [PubMed] [Google Scholar]

- 9.Suzuki E. Y, Suzuki B. Placement and removal torque values of orthodontic miniscrew implants. Am J Orthod Dentofacial Orthop. 2011;139:669–678. doi: 10.1016/j.ajodo.2010.11.017. [DOI] [PubMed] [Google Scholar]

- 10.Wilmes B, Rademacher C, Olthoff G, Drescher D. Parameters affecting primary stability of orthodontic mini-implants. J Orofacial Orthop. 2006;67:162–174. doi: 10.1007/s00056-006-0611-z. [DOI] [PubMed] [Google Scholar]

- 11.Cho K. C, Baek S. H. Effects of predrilling depth and mini-implant shape on the mechanical properties of orthodontic mini-implants during the insertion procedure. Angle Orthod. doi: 10.2319/080911-503.1. In Press. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Poggio P. M, Incorvati C, Velo S, Carano A. “Safe zones”: a guide for miniscrew positioning in the maxillary and mandibular arch. Angle Orthod. 2006;76:191–197. doi: 10.1043/0003-3219(2006)076[0191:SZAGFM]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 13.Wilmes B, Su Y. Y, Drescher D. Insertion angle impact on primary stability of orthodontic mini-implants. Angle Orthod. 2008;78:1065–1070. doi: 10.2319/100707-484.1. [DOI] [PubMed] [Google Scholar]

- 14.Lim J. E, Lee S. J, Kim Y. J, Lim W. H, Chun Y. S. Comparison of cortical bone thickness and root proximity at maxillary and mandibular interradicular sites for orthodontic mini-implant placement. Orthod Craniofac Res. 2009;12:299–304. doi: 10.1111/j.1601-6343.2009.01465.x. [DOI] [PubMed] [Google Scholar]

- 15.Lim S. A, Cha J. Y, Hwang C. J. Insertion torque of orthodontic miniscrews according to changes in shape, diameter and length. Angle Orthod. 2008;78:234–240. doi: 10.2319/121206-507.1. [DOI] [PubMed] [Google Scholar]

- 16.Brinley C. L, Behrents R, Kim K. B, Condoor S, Kyung H. M, Buschang P. H. Pitch and longitudinal fluting effects on the primary stability of miniscrew implants. Angle Orthod. 2009;79:1156–1161. doi: 10.2319/103108-554R.1. [DOI] [PubMed] [Google Scholar]

- 17.Migliorati M, Signori A, Silvestrini Biavati A. Temporary anchorage device stability: an evaluation of thread shape factor. Eur J Orthod. doi: 10.1093/ejo/cjr026. 2011 Apr 15. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 18.Hung E, Oliver D, Kim K. B, Kyung H. M, Buschang P. H. Effects of pilot hole size and bone density on miniscrew implants' stability. Clin Implant Dent Relat Res. doi: 10.1111/j.1708-8208.2010.00269.x. 2010 Mar 12. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 19.Florvaag B, Kneuertz P, Lazar F, Koebke J, Zöller J. E, Braumann B, Mischkowski R. A. Biomechanical properties of orthodontic miniscrews. An in-vitro study. J Orofac Orthop. 2010;71:53–67. doi: 10.1007/s00056-010-9933-y. [DOI] [PubMed] [Google Scholar]

- 20.Baumgaertel S, Hans M. G. Buccal cortical bone thickness for mini-implant placement. Am J Orthod Dentofacial Orthop. 2009;136:230–235. doi: 10.1016/j.ajodo.2007.10.045. [DOI] [PubMed] [Google Scholar]

- 21.Wilmes B, Ottenstreuer S, Su Y. Y, Drescher D. Impact of implant design on primary stability of orthodontic mini-implants. J Orofac Orthop. 2008;69:42–50. doi: 10.1007/s00056-008-0727-4. [DOI] [PubMed] [Google Scholar]

- 22.Kim J. W, Baek S. H, Kim T. W, Chang Y. I. Comparison of stability between cylindrical and conical type mini-implants. Mechanical and histological properties. Angle Orthod. 2008;78:692–698. doi: 10.2319/0003-3219(2008)078[0692:COSBCA]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 23.Kim S. H, Lee S. J, Cho I. S, Kim S. K, Kim T. W. Rotational resistance of surface-treated mini-implants. Angle Orthod. 2009;79:899–907. doi: 10.2319/090608-466.1. [DOI] [PubMed] [Google Scholar]

- 24.Cha J. Y, Takano-Yamamoto T, Hwang C. J. The effect of miniscrew taper morphology on insertion and removal torque in dogs. Int J Oral Maxillofac Implants. 2010;25:777–783. [PubMed] [Google Scholar]