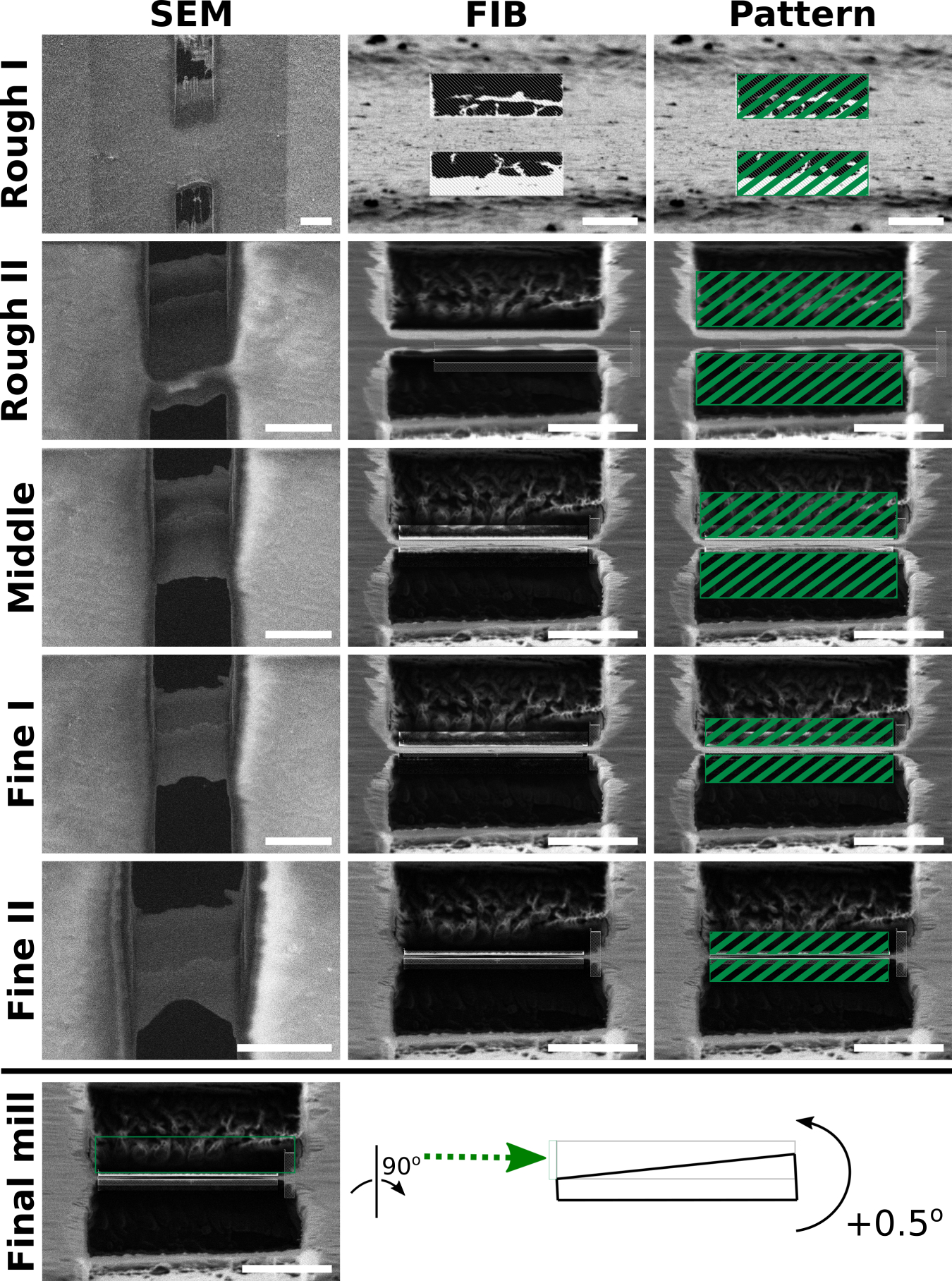

Figure 6: Overview of typical FIB milling progression.

SEM (left column) and FIB (middle column) views of one lamella milled from beginning to end. As material is removed, the lamella becomes more uniform and electron transparent seen from the SEM view. Additionally, the leading edge of the lamella becomes thinner seen from the FIB view. Third column: Schematic of milling patterns overlaid onto lamella FIB views (Table 4). Bottom row: schematic of final milling step with a +0.5° stage tilt to make lamellae of uniform thickness using only the top milling pattern and an additional +0.5° stage tilt. Green arrow represents the direction of the ion-beam milling. For the final step, only the top pattern is activated to selectively mill the thicker portion in the back. The milled area is indicated in grey. Scale bars: SEM images 10 μm; FIB images 5 μm.