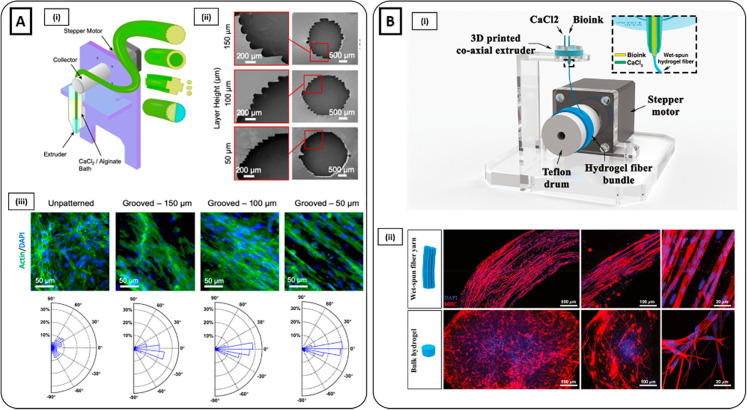

Figure 7.

Hydrogel microfluidic methods. (Ai) Schematic illustration of the wet-spinning device and the fabrication process of solid and hollow grooved hydrogel fibers with various cross-sectional shapes. (ii) SEM images of the microfluidic extruder with different grooved dimensions. (iii) Quantitative analysis of alignment for C2C12 myoblasts on the grooved fibers with three different groove sizes and unpatterned fibers based on the confocal microscopy images (F-actin green, nuclei blue). Cells on unpatterned fibers showed a random distribution. In contrast, myoblasts demonstrated alignment toward the grooves, which increased by decreasing the groove size from 150 to 50 μm (Reproduced with permission from ref (188). Copyright 2020 American Chemical Society). (Bi) Schematic representation of microfluidic spinning setup for the fabrication of hPM-laden hydrogel yarns. (ii) MHC (red) and nuclei (blue) staining of hPM-laden yarn and bulk sample (control) after 15 days of culture. Cell-laden yarns exhibited parallelly aligned MHC positive myotubes, while bulk samples showed a similar MHC expression but with a random myotube arrangement (Reproduced with permission from ref (193). Copyright 2020 The Authors, John Wiley and Sons CCBY-NC-ND 4.0).