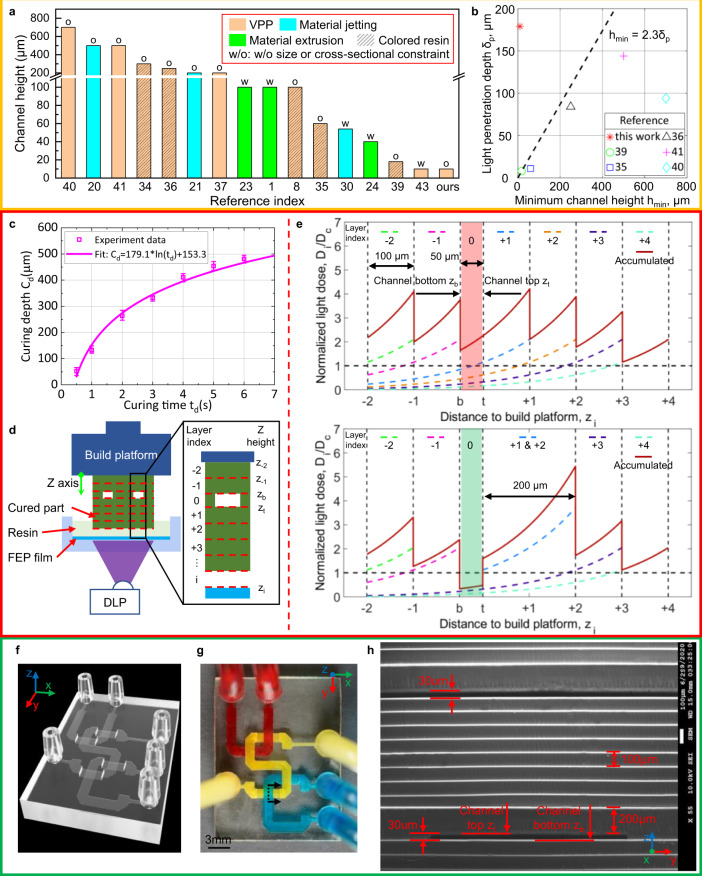

Fig. 1. Illustration of the effect of resin optical property and light dose distribution on VPP-based microfluidic channels fabrication.

a Summarization of literature on minimum printable channel height hmin and corresponding technical features. b Relationship between light penetration depth δp and minimum printable channel height hmin for VPP-based processes. c Measured results and fitted curve of curing depth cd and exposure time td for transparent resin. d Schematic diagram showing challenges in 3D printing transparent microfluidic channels. e Normalized light dose distribution of each projection and the accumulated light dose along the Z-direction when manufacturing the part in Fig. 1d via VPP (Top) and IsT-VPP (bottom). f CAD model of the crisscrossing USC-shaped fluid router. g Top view of the USC-shaped fluid router fabricated by IsT-VPP. h SEM image showing the cross-section of the channels indicated by the dashed line in Fig. 1 g. The result demonstrates 30-μm-height channels.