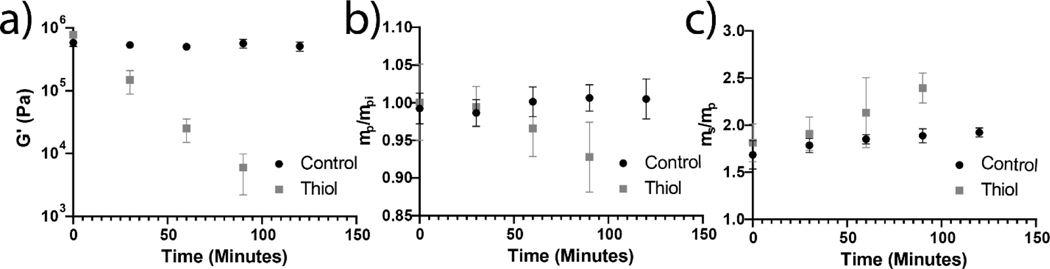

Figure 2:

Degradation of thioester elastomers placed in pH 9.0 buffer with and without 300 mM 2-mercaptoethanol was observed over 2 h. Degradation was only observed when 2-mercaptoethanol was present in solution suggesting degradation was mediated only by thioester exchange. a) Shear swollen moduli were observed as a function of time. An exponential decrease in modulus was observed for the thiol condition suggesting that crosslinks were cleaved throughout the sample via a bulk erosion mechanism. 0.1% strain, 1Hz; N = 3, error bars are standard deviation. b) Elastomer samples were lyophilized measured for polymer mass. Dry mass data were normalized to the calculated theoretical amount of polymer included in formulation and plotted here as a function of time and degradation condition. N = 3, error bars are 95% confidence interval. c) Mass swelling ratio was calculated as the ratio of the swollen polymer mass to the measured dry mass and are reported here as a function of time and degradation condition. N = 3, error bars are 95% confidence interval.