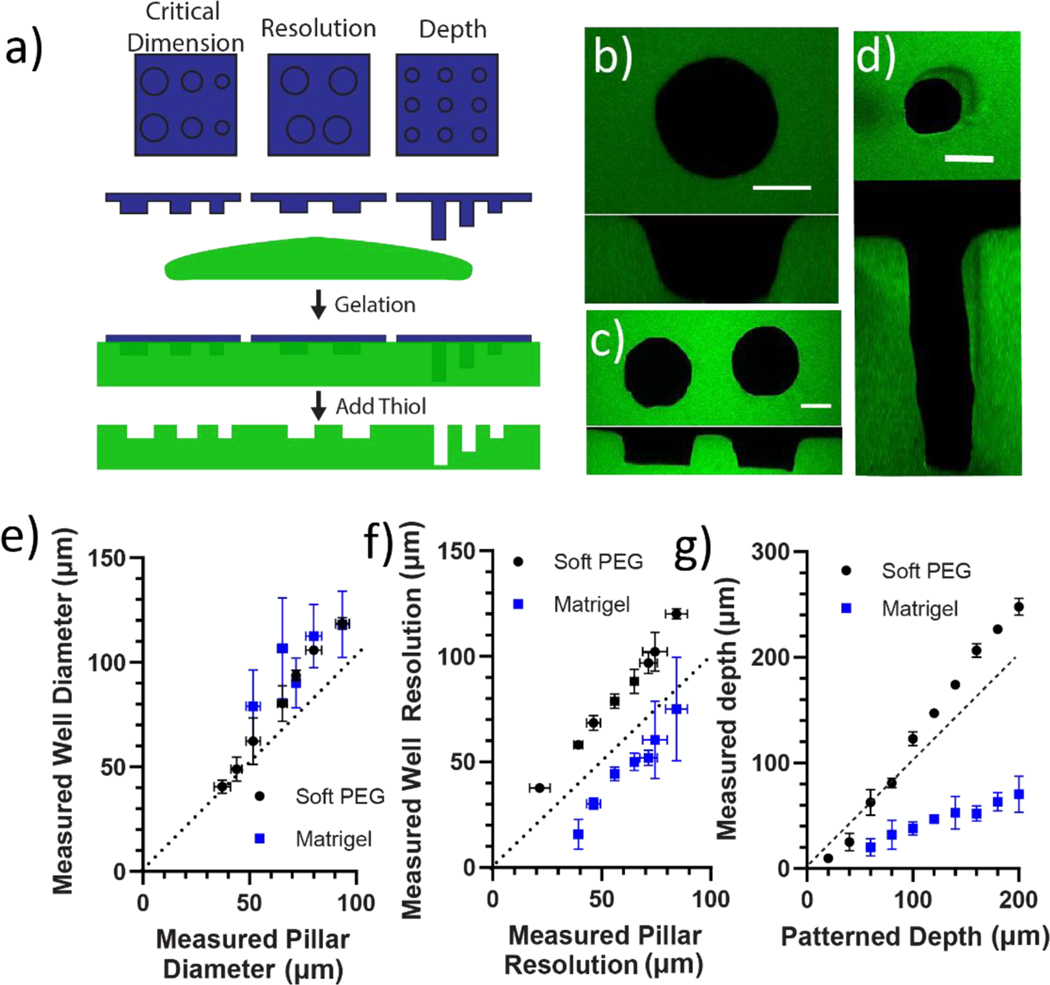

Figure 4:

Thioester elastomer structures were degraded in situ to cast patterns into soft, swollen hydrogel platforms. a) 3D printed thioester elastomer constructs were lowered into solutions of Matrigel or 8-arm 20 kDa PEG norbornene and 2-arm 5 kDa PEG thiol combined in a stoichiometric ratio diluted to 2 wt% (G’ = 740±50 Pa). Each hydrogel was polymerized, then a solution of pH 9.0 300 mM 2-mercaptoethanol was added to degrade the thioester elastomer stamp. Hydrogel cast patterns were then equilibrium swollen in PBS and imaged by laser scanning confocal microscopy to assess how printed pillar dimensions transfer to each hydrogel substrate. b) 50 μm tall pillars with a range of diameters were patterned into Matrigel and Soft PEG hydrogels. Z-stack images of each well were taken with laser scanning confocal microscopy. Well diameter was measured between10–20 μm from the bottom of the well using MATLAB (for more details please see methods).A representative image is shown of a well cast by a 90 μm diameter pillar into PEG hydrogel. An orthogonal view of the XZ plane is included for reference c) 50 μm tall, 100 μm diameter pillars with a range of spacing were patterned into Matrigel and Soft PEG hydrogels. Z-stack images of each well were taken with laser scanning confocal microscopy. Well resolution was measured between10–20 μm from the bottom of the well using MATLAB (for more details please see methods).A representative image is shown of a pair of wells cast by pillars 30 μm apart into PEG hydrogel. An orthogonal view of the XZ plane is included for reference. d) 50 μm diameter pillars with a range of printed heights were patterned into Matrigel and Soft PEG hydrogels. Z-stack images of each well were taken with laser scanning confocal microscopy. Well depth was measured as the number of image slices multiplied by the image thickness (for more details please see methods).A representative image is shown of a well cast by a 200 μm tall pillar into PEG hydrogel. An orthogonal view of the XZ plane is included for reference. e) The measured well diameter in Matrigel and soft PEG hydrogels is plotted versus the measured pillar diameter in the elastomer print. f) The measured well separation in Matrigel and soft PEG is plotted versus the pillar separation measured for the elastomer print. g) The measured well depth in Matrigel and soft PEG is plotted versus the designed height of the elastomer print. PEG hydrogels were visualized by 2000 kDa FITC dextran entrapped in network. Scale bars 50 μm. n = 3 patterned hydrogels each containing 3 technical replicates averaged together.