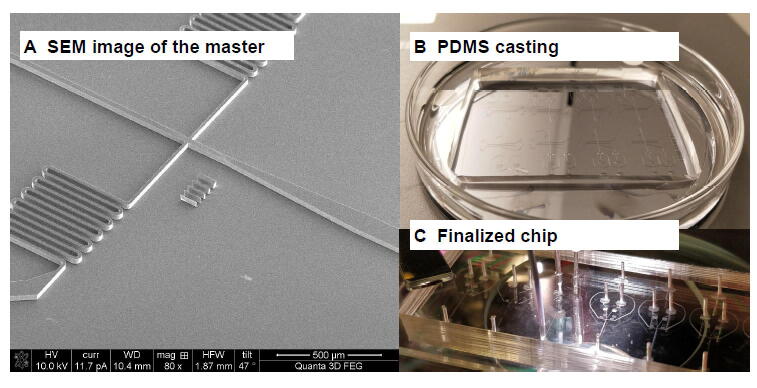

Figure 2.

Fabrication of silicon-based master molds and PDMS chips

A. SEM image of the master mold for a droplet generator device. The channel features are well defined with smooth surfaces and straight walls. B. Casting of PDMS over the master mold. We prepared a mixture of the polymeric base and the curing agent (10:1) as suggested by the Sylgard® 184 Silicone-based Elastomeric Kit. This mixture was degassed in a vacuum chamber and then poured on top of the silicon master. Once the PDMS mixture is fully cross-linked, the inlets/outlets are punched, and the resulting PDMS replica is bonded to a glass slide using O2 plasma treatment. C. The inset presents an example of a finalized chip. SEM, scanning electron microscopy; PDMS, polydimethylsiloxane.