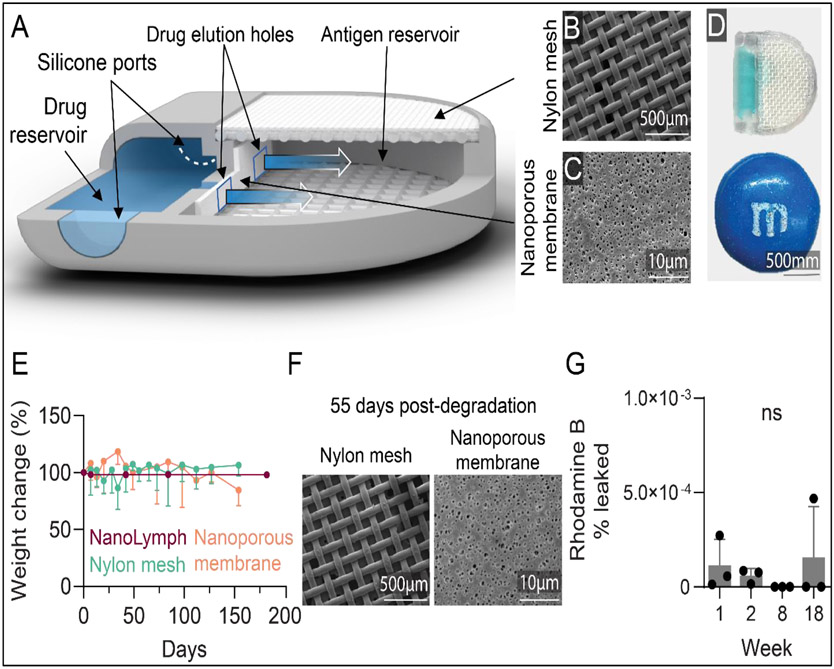

Figure 2: NanoLymph design and characterization.

(A) Rendering of NanoLymph cross-section with view of drug and antigen reservoir as well as self-sealing silicone loading ports on opposing sides. (B) SEM image of nylon woven mesh membrane; scale bar 500 μm. (C) SEM image of polyethersulfone (PES) nanoporous membrane; scale bar 10 μm. (D) NanoLymph shown to scale in comparison with commercially available M&M™; scale bar 500 mm. (E) Degradation of NanoLymph components in vitro as function of change in weight from baseline. Horizontal dotted line indicates 75% weight change. NanoLymph in purple, nylon mesh in teal, nanoporous membrane in orange. (F) SEM image of nylon woven mesh (scale bar: 500 μm) and PES nanoporous membrane (scale bar: 10 μm) 55 days after incubation at 67 °C (G) Percent of rhodamine B leaked from in vitro implants after 18 weeks