Table 2.

Properties of synthetically-derived biogenic polymers used in food packaging.

| Biogenic Polymer | Monomeric Unit | Structure of Monomeric Unit |

Properties |

|---|---|---|---|

| Synthetic Biogenic Polymer | |||

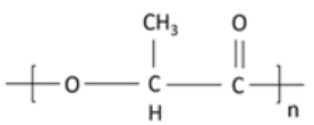

| Polylactic acid (PLA)/Polylactide | Lactic acid/lactide |  |

Non-toxic, biodegradable, aliphatic polyester [132]. Produced from lactic acid either by polycondensation reaction or through ring-opening polymerization of lactide monomer [133]. Derived from renewable sources such as starch and/or sugar [134]. Reduced carbon emissions (15% to 60%) and 25% to 55% lower energy consumption in comparison to petroleum-based polymers [135]. Enhanced strength, transparency, fracture strain, and high elastic modulus [136]. Glass transition lies between 50–80 °C, and its crystalline melting temperature varies from 130 and 180 °C [137]. |

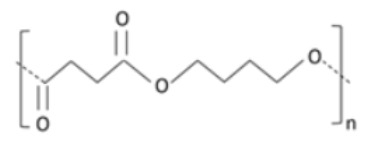

| Poly(butylene succinate) (PBS) | Succinic acid and butanediol |

|

Aliphatic polyester [138]. Polycondensation product of bio-based succinic acid and 1,4 butanediol [139]. Exhibits good elongation properties [140]. Poor gas barrier characteristics [141]. Highly crystalline [142]. Is stiff. High crystallinity results in a reduced rate of degradation, because of its highly-coordinated structure [143]. |

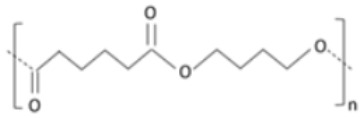

| Polybutylene succinate adipate (PBSA) | Succinic acid, adipic acid and butanediol |

|

Semi-crystalline polyester produced by co-condensation of succinic and adipate acid with 1-4-butanediol. |