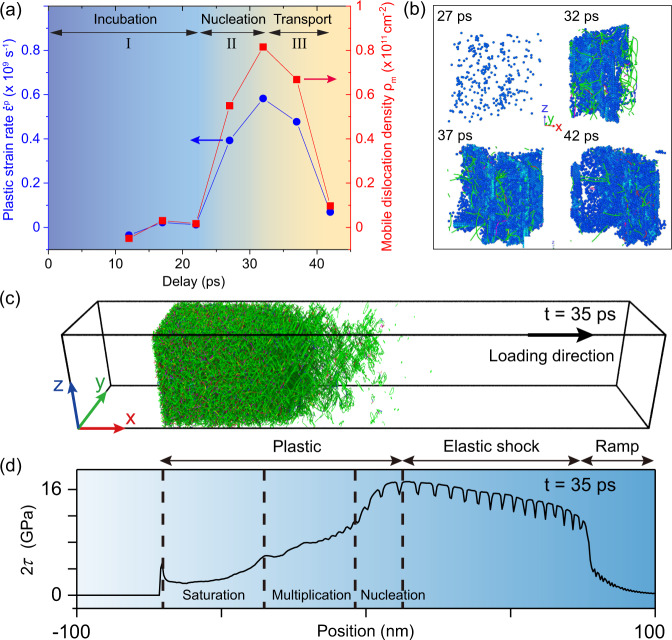

Fig. 4. Dislocation dynamics of (110) single-crystal Al under laser-driven compression at 4.3 ± 0.4 J cm−2.

a Plastic strain rate (; blue line + dots) and mobile dislocation density (ρm; red line + squares) from UED experiments. Stages I–III correspond to incubation (no dislocations), dislocation nucleation, and dislocation transport, respectively. b–d are MD simulation results obtained at the fluence of 4.3 J cm−2; b Snapshots of atomic configuration at a selected cubical region with 8-nm-long edges, showing dislocation nucleation and transport during plastic deformation. Lines of different colors represent different types of dislocations, with Shockley partial dislocations in green and perfect dislocations in blue. Blue dots are atoms with finite von Mises shear strains. c Overall dislocation structure obtained at a time delay of 35 ps; the size of the y–z cross section is 35 nm × 35 nm; the same color coding as in (b) is applied for the displayed dislocation lines. d the shear stress (2τ) profile of (c), showing three regions of the stress relaxation with the dislocation evolution dominated by nucleation, multiplication (transport), and saturation.