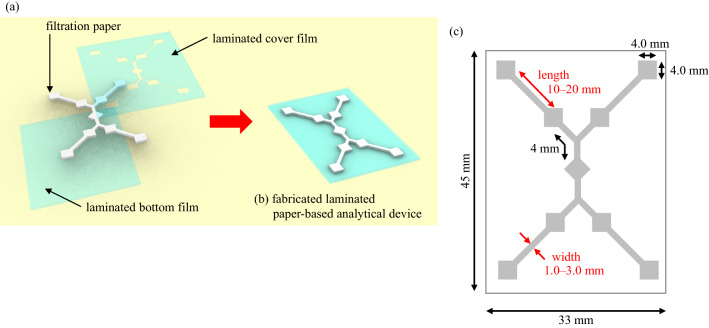

Figure 1.

Fabrication of the laminated paper-based analytical device (LPAD). (a) The designed paper channels were sandwiched between the cover and bottom laminate films, aligned, and assembled. The assembly was passed through a heated laminator. The illustration was drawn with “Rhinoceros ver. 6” 3D-CAD software28. (b) An illustration of the fabricated device. (c) Dimensions of the microfluidic paths of the LPAD. Several path lengths and widths between the enzymatic reaction area and detection area were fabricated. The optimized length was 15 mm and width was 3.0 mm.