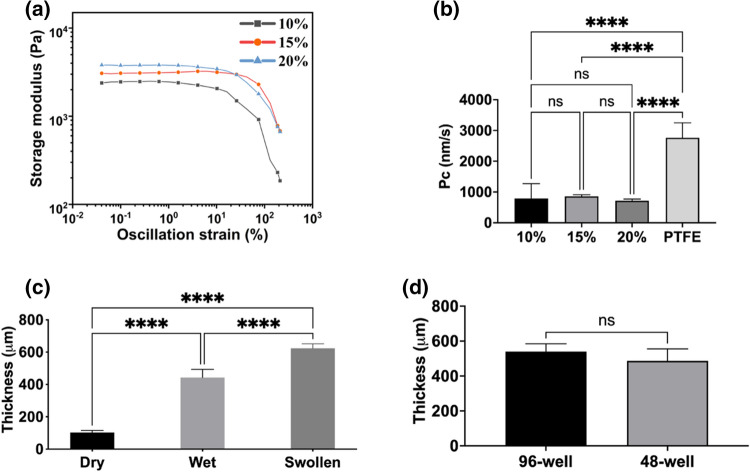

Figure 3.

Determination of mechanical properties of 10% w/v (10%), 15% w/v (15%), 20% w/v (20%) gelatin membranes. (a) Analysis of storage and loss modulus of each membrane under applied oscillatory compression. (b) Comparison of 20 µM Fluorescein sodium salt dye transport through each membrane assembled to 96-well plate format 3D-printed strip insert wells (10–20%: n = 4; PTFE: n = 7). Insert well aperture surface area for transport is 0.05 cm2. (c) Determination of thickness changes of 15% (w/v) Gelatin membranes assembled to 48-well format (Ø: d = 8.8 mm; a = 4 mm); wet (n = 5), swollen (n = 5), and dry (n = 5). (d) Thicknesses measurement of 15% (w/v) gelatin membranes (n = 5) via fluorescence intensity analysis. Error bars indicate mean ± SD. Statistical significance: ns = P > 0.05, ****P < 0.0001.