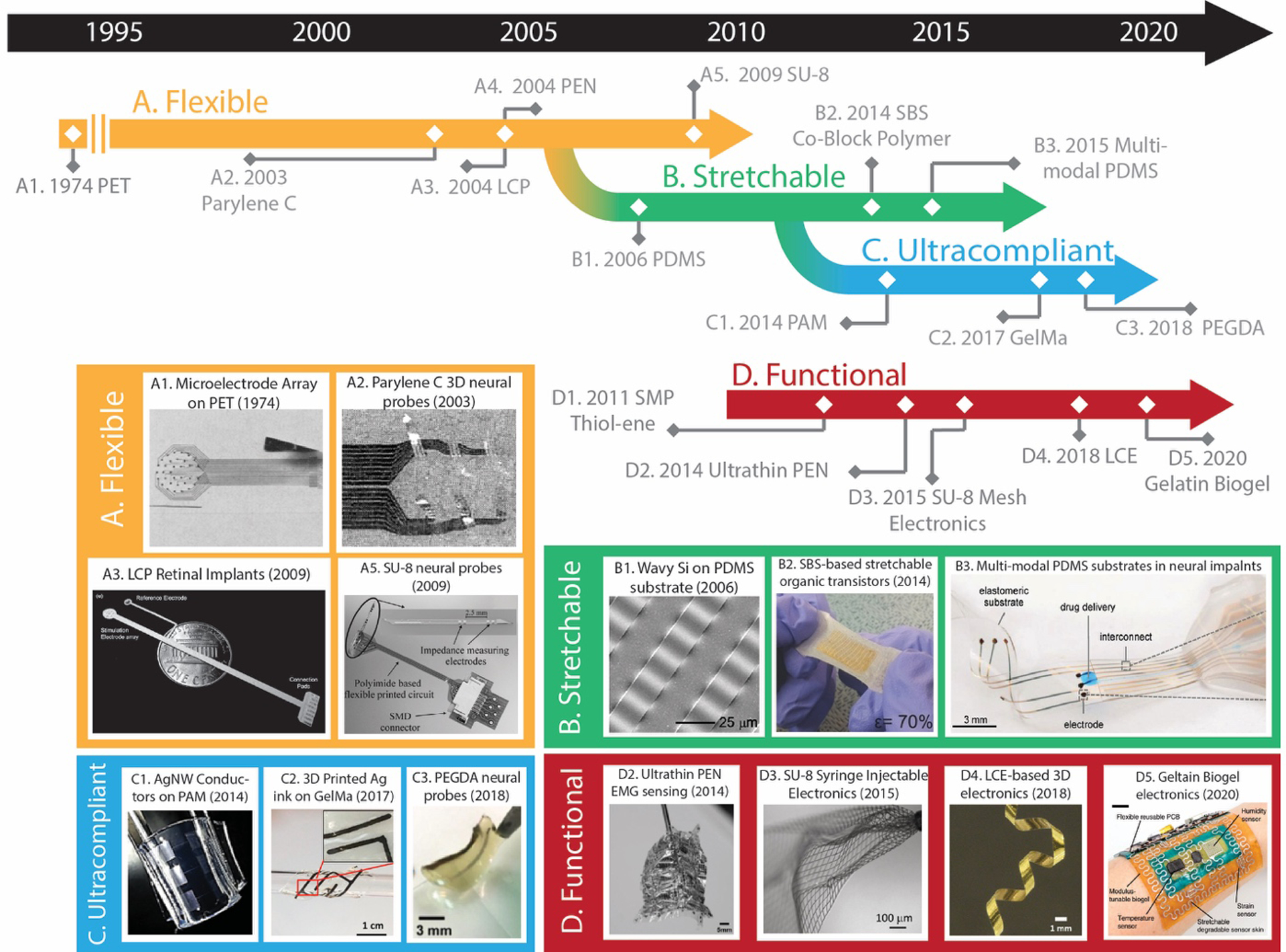

Figure 2.

Timeline outlining the evolution of mechanically compliant substrates in bioelectronics towards softer devices designed to maximize biological integration. Substrate materials are roughly classified into four categories – A. Flexible, B. Stretchable, C. Ultracompliant, and D. Structurally Adaptive. Key advances from each category have been presented on the timeline and select examples have been featured through the following pictures: A1. Polyethylene Terephthalate (PET). Reproduced with permission.[117] Copyright 1974, Springer Nature. A2. Parylene C. Reproduced with permission.[118] Copyright 2003, IEEE. A3. Liquid crystal polymers (LCPs). Reproduced with permission.[119] Copyright 2009, Association for Research in Vision and Ophthalmology. A5. SU-8 epoxy. Reproduced with permission.[120] Copyright 2009, Elsevier. B1. Stretchable Si on PDMS. Reproduced with permission.[121] Copyright 2006, The American Association for the Advancement of Science. B2. Organic transistors on styrene-butadiene-styrene (SBS). Reproduced with permission.[122] Copyright 2014, John Wiley and Sons. B3. Muti-modal PDMS electronic dura mater. Reproduced with permission.[123] Copyright 2015, The American Association for the Advancement of Science. C1. Silver nanowires on polyacrylamide. Reproduced with permission.[124] Copyright 2014, American Chemical Society. C2. Printed silver flakes on gelatin methacrylate (GelMa). Reproduced with permission.[125] Copyright 2017, Elsevier. C3. Transfer printed polyethylene glycol-dopamine (PEGDA). Reproduced with permission.[126] Copyright 2017, John Wiley and Sons. D2. Ultrathin 1 μm polyethylene napthalate (PEN). Reproduced with permission.[127] Copyright 2014, IEEE. D3. Syringe injectable SU-8. Reproduced with permission.[128] Copyright 2015, Springer Nature. D4. Morphing electronics on a liquid crystal elastomer. Reproduced with permission.[129] Copyright 2019, American Chemical Society. D5. Transient devices on gelatin biogels. Reproduced with permission.[130] Copyright 2020, Springer Nature.