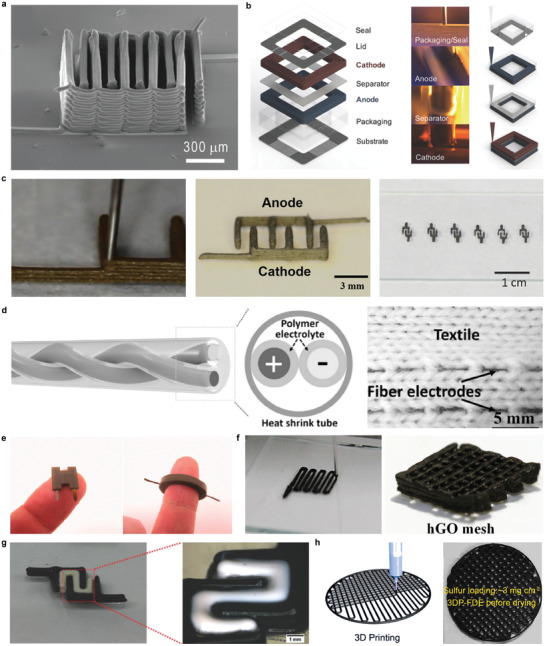

Figure 9.

3D‐printed batteries. a) SEM of printed and annealed 16‐layer interdigitated LTO‐LFP electrode architectures. b) Schematic illustration of fully 3D‐printed Li‐ion square cell battery. c) Photograph of showing the multilayered structure being printed(left), the interdigitated electrodes(middle), and 3D‐printed electrode arrays(right). d) Schematic illustraion of the design concept for all‐fiber flexible LIBs(left) and a photograph of integration of fiber electrodes into textile fabrics(right). e) Photographs of assembled Zn‐PANI batteries in ring‐, H‐, and cylindrical shapes. f) Photograph of showing the process of printing complex 3D architectures line‐by‐line(left) and printed hGO mesh (0.8 mm line spacing). g) Photograph of the 3D‐printed interdigitated full cell battery composed of LTO/INK‐2/LFP. h) Schematic illustration of the 3D‐printing process for S/BP 2000 thick cathodes(left) and photograph of fabricated with a grid structure of 3DP‐FDE(right). a,b) Reproduced with permission.[ 5 ] Copyright 2018, Wiley‐VCH. c) Reproduced with permission.[ 159 ] Copyright 2016, Wiley ‐VCH. d) Reproduced with permission.[ 160 ] Copyright 2017, Wiley‐VCH. e) Reproduced with permission.[ 161 ] Copyright 2018, American Chemical Society. f) Reproduced with permission.[ 162 ] Copyright 2018, Wiley‐VCH. g) Reproduced with permission.[ 164 ] Copyright 2018, Wiley‐VCH. h) Reproduced with permission.[ 165 ] Copyright 2018, Elsevier.