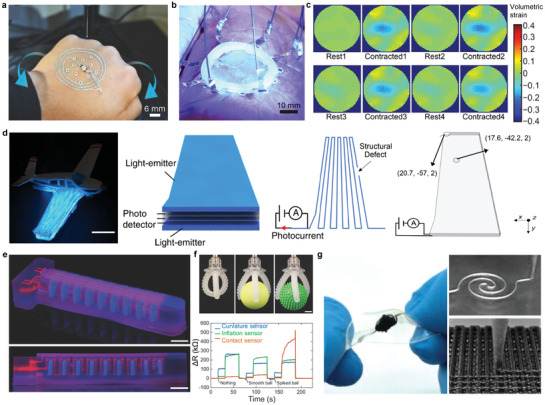

Figure 11.

3D‐printed sensors. a) Photograph of adaptive 3D printing of the wireless moisture sensor on a human hand that can move freely in the workspace. b) Photograph of deformation sensors printed on a porcine lung. c) Spatiotemporal mapping of volumetric strain within the region‐of‐interest on a porcine lung undergoing cyclic contraction. d) Application of a printed bi‐functional light‐detecting and light‐emitting 3D‐structure for detecting structural defects of model airplane. Scale bar, 2 cm. e) Fluorescence image of integrated sensory robotic gripper. The actuator (blue) and sensor (red) inks have been fluorescently dyed to facilitate visualization. Scale bars, 10 mm. f) Top: Photographs showing the gripper holding nothing (left), a smooth ball (middle), and a spiked ball (right). Scale bar, 20 mm. Bottom: Resistance change of curvature, inflation, and contact sensors as a function of time. g) Photographs of 3D‐printed piezoresistive sensor and its magnified views of electrode layer and sensing layer. a) Reproduced with permission.[ 58 ] Copyright 2018, Wiley‐VCH. b,c) Reproduced with permission.[ 187 ] Copyright 2020, American Association for the Advancement of Science. d) Reproduced with permission.[ 188 ] Copyright 2019, Springer Nature. e,f) Reproduced with permission.[ 189 ] Copyright 2018, Wiley‐VCH. g) Reproduced with permission.[ 190 ] Copyright 2019, Wiley‐VCH.