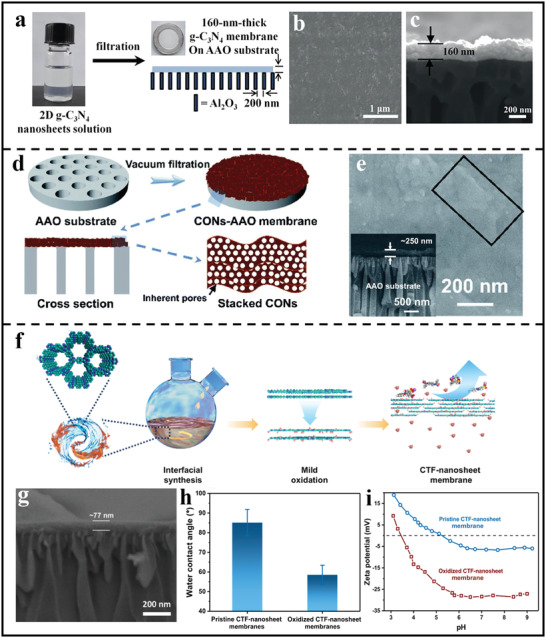

Figure 6.

Composite membrane preparation based on 2D polymer nanosheets via vacuum‐assisted assembly. a) Fabrication process of g‐C3N4 membrane formed on AAO support. b) Surface and c) cross‐sectional SEM images of g‐C3N4 nanosheets‐assembled membrane supported on porous AAO substrate. (a–c) Reproduced with permission.[ 65 ] Copyright 2020, American Chemical Society. d) Scheme of depositing imine‐linked 2D polymer nanosheets on AAO supports to prepare the composite membrane. e) SEM image of the membrane surface, inset is the cross‐sectional morphology of the composite membrane. (d,e) Reproduced with permission.[ 53 ] Copyright 2019, Royal Society of Chemistry. f) Schematic diagram for preparing CTF‐nanosheets through dynamic liquid/liquid interface polymerization. g) Cross‐sectional SEM images of oxidized CTF nanosheets‐assembled membranes. h) Water contact angles and i) zeta potentials of the pristine and oxidized CTF nanosheets‐assembled membranes. (f–i) Reproduced with permission.[ 66 ] Copyright 2020, American Chemical Society.