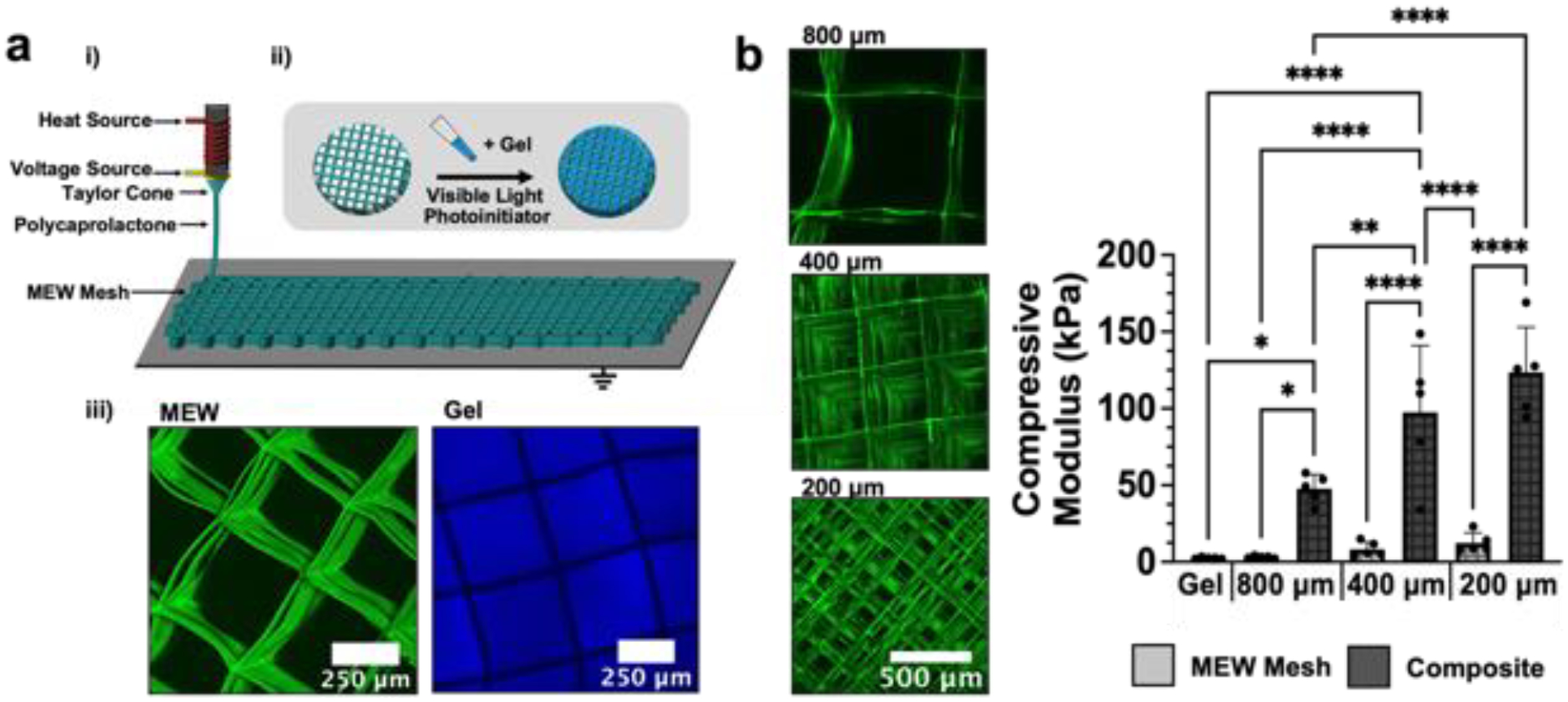

Figure 4: PCL meshes reinforce soft NorHA hydrogels.

(a) (i) Schematic of the melt-electrowriting process (MEW) employed to fabricate fibrous PCL meshes. PCL is heated to form a polymer melt that can be readily extruded though a printhead with an attached voltage source to deposit PCL onto a grounded print bed. (ii) PCL meshes are then filled with NorHA macromer/crosslinker precursor (2 kPa NorHA hydrogel formulation) and exposed to visible light in the presence a photoinitiator to form composites. (iii) Images of composites containing PCL MEW meshes (green) and 2 kPa NorHA hydrogel (blue). (b) Representative images of MEW meshes of varied interfiber spacing (800 μm, 400 μm, 200 μm). Compressive moduli of NorHA hydrogel alone, PCL MEW meshes of varied interfiber spacing alone, and composites containing NorHA hydrogel infused into meshes with varied interfiber spacing. *p<0.05, **p<0.01, ****p<0.0001, n=5.