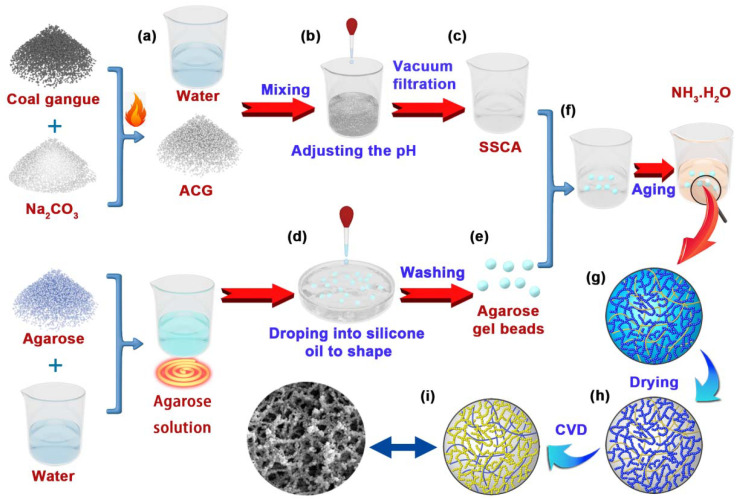

Figure 1.

Schematic of the SCAB preparation process. (a) Activated coal gangue (ACG) is prepared by calcining a mixture of coal gangue and Na2CO3, then adding deionized water. (b) The pH of the suspension is adjusted. (c) SiO2 sol containing Al3+ (SSCA) is obtained by vacuum filtration. (d) Agarose wet gel beads formed via the agarose (a linear polymer with a long chain alternately linked to 1,3-linked β-D-galactose and 1,4-linked 3,6-endoether-L-galactose) solution are dropped into the silicone oil. (e) After washing, clean agarose wet gel beads are obtained. (f) The agarose wet gel beads are soaked in SSCA. (g) After aging and soaking in NH3·H2O solution, SiO2–Al2O3/agarose composite wet gel beads are obtained. (h) The wet gel beads are supercritically dried to obtain SCABs. (i) Hydrophobic SCABs are obtained via CVD process.