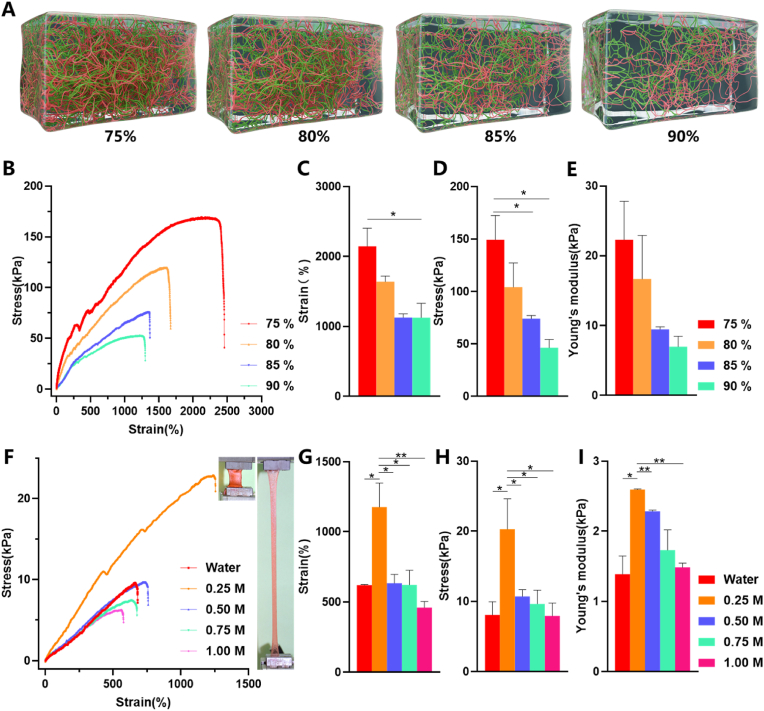

Fig. 2.

The tensile properties of patch matrix soaked in different calcium concentrations and different water contents. (A) Schematic diagram of patch matrix with different water content. (B) Stress–strain curves of the hydrogel matrix with different water content. (C) The elongation at break (%) of patch matrix with different water content. (D) The tensile strength of patch matrix with different water content. (E) The Young's modulus of patch matrix with different water content. All the matrix used from (B) to (E) were soaked in 0.25 M calcium ion for 24 h and then dried naturally in the air to reduce water content. (F) Stress–strain curves of the hydrogel matrix soaked in different calcium concentrations for 24 h. The inset of (F) shows a sample with a dimension of 15 mm in length, 10 mm in width, and 2 mm in thickness without stretch (left) and while stretched to 800% (right). (G) The elongation at break (%) of patch matrix soaked in different calcium concentrations. (H) The tensile strength of patch matrix soaked in different calcium concentrations. (I) The Young's modulus of patch matrix soaked in different calcium concentrations. Data are presented as mean ± SD. *P < 0.05 and **P < 0.01, significant difference among different group.