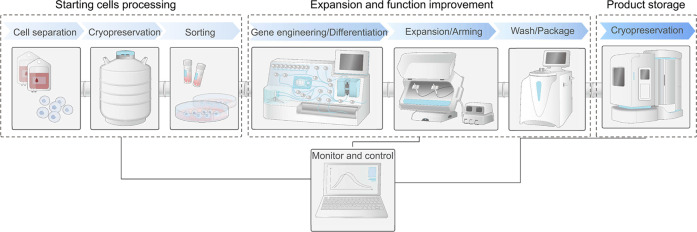

Fig. 3.

“Unattended” intelligent NK cell factory with “off-the-shelf/customized/self-supporting” capabilities. It is expected that, the NK cells manufacturing just likes an assemble-line, composed of three steps: (1) Starting cell processing and storage, includes starting cell selection, separation and cryopreservation; (2) Expansion and function improvement, including NK cell culture, gene engineering, quality control system and packaging; (3) Storage, the products are cryopreserved. During the manufacturing process, an quality control system involves automatic sampling, test result evaluation and intelligence adjustment of the production process is interacted with the monitor and control system. All the information of the samples, tests and processes running parameters are monitored and controlled by the Monitor and control system