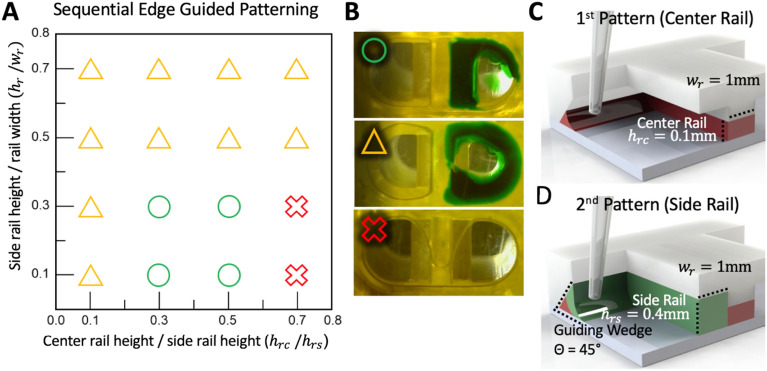

Fig. 2.

Detailing the specifics of the novel sequential edge guided patterning mechanism. A A graph of the solution space of dimensions required for utilizing the wedge to rail capillary flow mechanism to sequentially pattern a primary central and secondary side rail utilizing the same wedge, for up to three (one central and two side) patterns within a unit chip. B Illustrates the success and failure conditions for patterning. The green circle denotes a successful 1st center rail and 2nd side rail patterning. The yellow triangle shows a successful 1st center rail patterning, but a failed 2nd side rail pattern due the inability for the 2nd pattern to fill the side rail. The red x denotes a 1st center rail pattern failure. C Shows a rendering of a successful 1st center rail patterning utilizing the optimized dimensions of the platform. D Shows a rendering of a successful 2nd side rail patterning utilizing the optimized dimensions of the platform