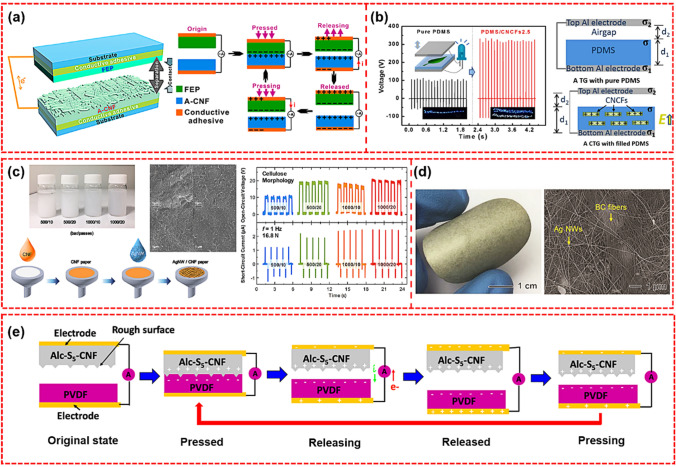

Fig. 8.

a Structure of a TENG that uses the A-CNFs film as a contact material, working principle of the A-CNFs-based TENG, and stability and durability test of the TENG after 10,000 cycles [161]. b Performance comparison of pure PDMS and PDMS/CNCFs, and illustration of the triboelectric contact electrification processes with the net electric field E in composite films along the direction from the PDMS to the top Al electrode [162]. c CNFs paper: CNFs dispersions homogenized at 500 bar and 1000 bar and different numbers of passes (10, 20). Schematic of AgNWs/CNFs paper fabricated using a vacuum-filtration technique. SEM images of cellulose surface with different morphologies. And electrical output of TENG (open-circuit voltage and short-circuit current) depending on cellulose morphology [163]. d Photograph and SEM image of the BC composite paper, and picture showing an electric circuit and an array of 200 lit LED bulbs during the circuit operation by the large-area BC-TENG [165]. e Schematic illustration of the operating principle of the TENG device [166]