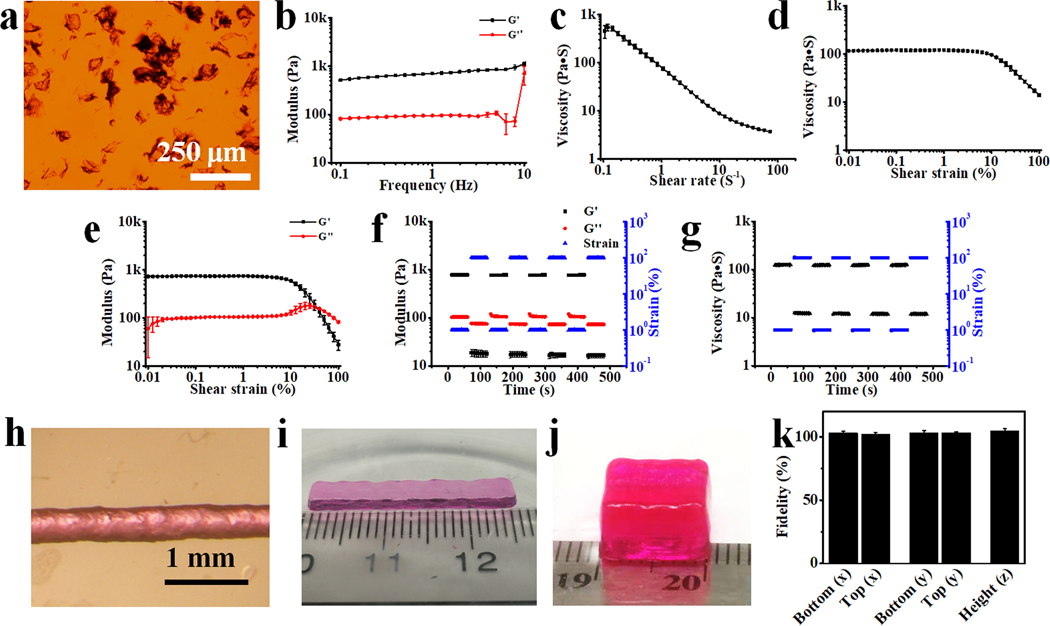

Figure 1.

(a) Photomicrograph of safranin O stained MFHs. (b) Schematics showing lower packing density of granular microgels (upper) and more highly packed irregular MFHs (bottom). (c) Storage (G’) and loss (G”) moduli of MFHs as a function of frequency. Material viscosity decreases while continuously increasing (d) shear rate and (e) shear strain over 10% strain. (f) Crossover of G’ and G” with increasing shear strain indicative of shear yielding. Rapid recovery of MFHs’ (g) modulus and (h) viscosity by alternating the applied strain between 1% and 100%. (i) Photomicrograph of a filament printed through a 22-gauge (22G) needle (inner diameter 413 μm). Photographs of 3D printed (j) hydrogel bar (25 × 4 × 1 mm3) and (k) hydrogel cuboid (10 × 8 × 6 mm3). (l) Fidelity of the as-printed 3D construct in j before UV crosslinking. Data are presented as mean ±standard deviation (± SD), N = 3.