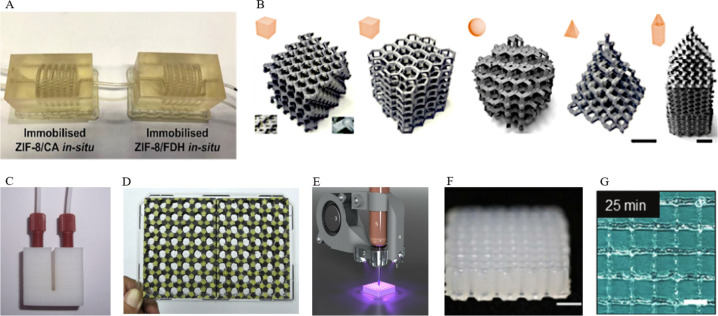

Figure 1.

(A) Arrangement of two micromixers in series with carbonic anhydrase (CA) and formate dehydrogenase (FDH) enzymes immobilized in separate micromixers (domino immobilization) of SLA 3D printing for the enzymatic cascade reduction of CO2. Reprinted with permission from ref (11c) Copyright 2021 Elsevier. (B) Digital images of FDM 3D-printed scaffolds for enzymes immobilization. Reprinted from ref (12b). Copyright 2019 American Chemical Society. (C) Photograph of the FDM printed reactor. Reprinted from ref (12c). Copyright 2016 American Chemical Society. (D) Photograph of two FDM printed enzyme/substrate-incorporated 48-well plates (side-by-side/layer-by-layer design) glued onto a transparent polystyrene microplate, with glucose oxidase immobilized near the center of each well. Reprinted with permission from ref (12d). Copyright 2018 Elsevier. (E) Photograph of an extrusion-based printer: Cure-on-dispense setup used in combination with a Gesim BioScaffolder 3.1. Reprinted with permission from ref (13b). Copyright 2020 Frontiers Media S.A. (F) Side view of 3D-printed lattice structures. Reprinted with permission from ref (13a). Copyright 2021 Institute of Physics Publishing. (G) The image of three-dimensional printed grid pattern using preheated gelatin 10 represents proper gelation. Reprinted with permission from ref (13c). Copyright 2020 Whioce Publishing Pte. Ltd.