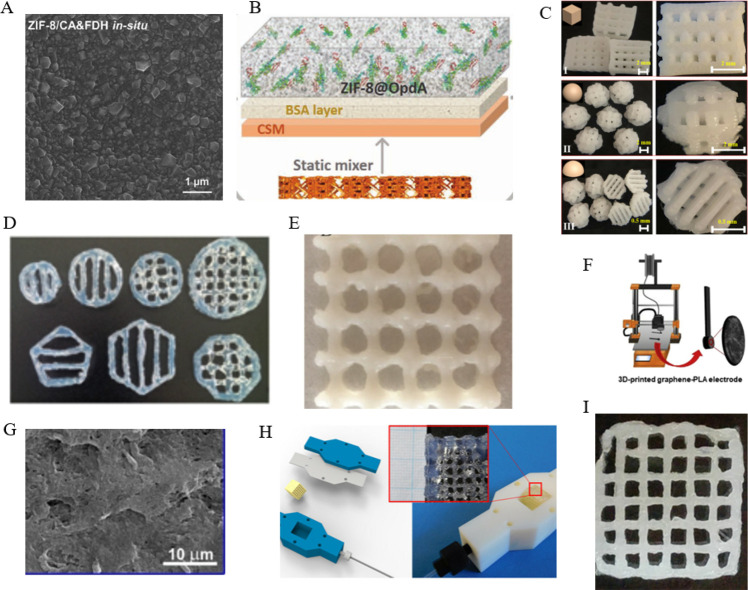

Figure 2.

Various 3D printing materials for enzyme immobilization. (A) SEM image of ZIF-8/carbonic anhydrase (CA) and formate dehydrogenase (FDH) in situ thin film. Reprinted with permission from ref (11c). Copyright 2021 Elsevier. (B) Image of in situ metal–organic framework growth and encapsulation process. Reprinted with permission from ref (15c). Copyright 2020 Elsevier. (C) Digital images of three types of 3D-printed polylactic acid scaffolds with adjustable aperture structures: cube (I), sphere (II), and semicircle (III). Reprinted with permission from ref (16d). Copyright 2021 Elsevier. (D) Agarose hydrogel scaffolds of different shapes and sizes can be printed. Reprinted with permission from ref (17b). Copyright 2018 John Wiley and Sons Ltd. (E) Picture of the 3D bioprinted constructs with the ratio of acrylamide: hydroxyapatite/sodium alginate = 4:1.2:1. Reprinted with permission from ref (17d). Copyright 2020 Elsevier. (F) 3D printing of the graphene-polylactic acid electrode. Reprinted with permission from ref (16a). Copyright 2020 Elsevier. (G) SEM micrographs of the carbon black-polylactic acid electrode surface after electrolysis in 1 M NaOH (−1.4 to +1.2 V vs the Ag|AgCl polarization range). Reprinted with permission from ref (16b). Copyright 2022 Elsevier. (H) Hydrogel structure is inserted in the reactor housing with connection to the fluidic system. Reprinted with permission from ref (17a). Copyright 2018 Frontiers Media S.A. (I) Top view image of the printed hydrogels using the additives Deuteron XG. Reprinted with permission from ref (17c). Copyright 2018 John Wiley and Sons Ltd.