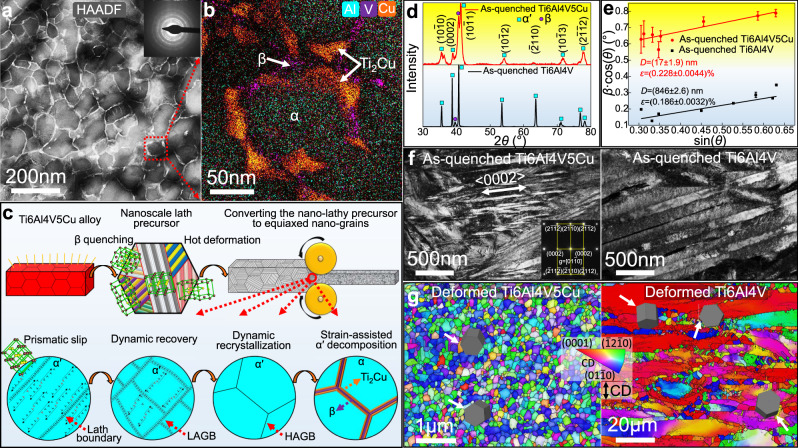

Fig. 2. Microstructure and formation mechanisms.

a Transmission electron microscopy (TEM) performing under the high-angle annular dark field (HAADF) mode of the as-prepared Ti6Al4V5Cu alloy. b X-ray energy dispersive spectroscopy (XEDS) analysis. c Schematic showing the eutectoid element alloying, quenching and hot deformation (EQD) fabricating strategy. d X-ray diffraction analysis (XRD) of as-quenched materials. e β·cos(θ) versus sin(θ) curves. Lattice strain ε and crystalline domain size D were determined by slopes and intercepts of curves. Error bars indicate standard deviations of measured β·cos(θ) value. f TEM bright field images of as-quenched materials. g Inverse pole figures (IPF) of deformed materials, compressive direction (CD) is denoted in the figure.