Table 1.

Halochromic composite films based on red cabbage anthocyanin: physical and mechanical changes.

| Biopolymer/ Polymer |

Application | pH Values/Color Change | Main Results after RCAs Incorporation | References | ||

|---|---|---|---|---|---|---|

| Physical Properties | Mechanical Properties |

|||||

| TS | EAB | |||||

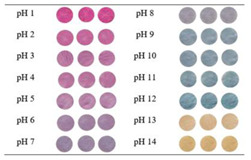

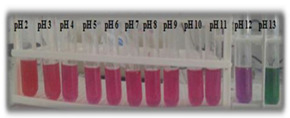

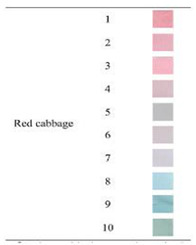

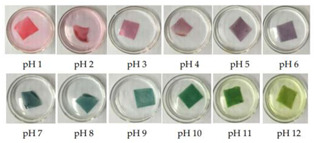

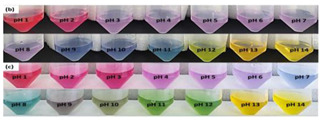

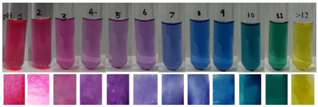

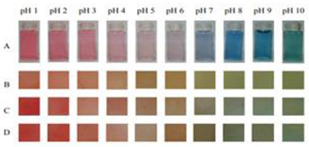

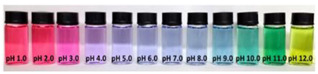

| Bacterial cellulose membrane | Intelligent packaging film for milk | pH = 1–14, color variation from red to purple, gray, and then to yellow

|

Significant increase in water solubility and swelling index |

↓ | ↑ | [19] |

| Sago starch | Intelligent packaging film | pH = 1–13, clearly color changes between pH 4, 9 and 13

|

Decrease in moisture content | _ | _ | [67] |

| Ethylene-vinyl acetate/ZnO/Fe-MMT nanoparticles | Smart packaging film | pH = 2–12, red to yellow

|

_ | _ | _ | [66] |

| Green banana starch/gelatin/alginate | Intelligent packaging film for sheep meat | pH = 2–13

|

Decrease in thickness, swelling Index and WVP |

_ | _ | [56] |

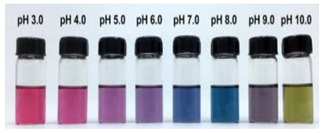

| ASK Gum/CMC·Na | Intelligent packaging film | pH = 3–10 (pink to green) (pH = 3 (rose–bengal), pH = 4–6 (purple), pH = 7 (bluish black), pH = 8–9 (atropurpureus), and pH = 11 (aquamarine))

|

Increase in WVP and light transmission, transparency; increase in OP value with increases in RCA content from 5 to 15% |

↓ | ↑ | [41] |

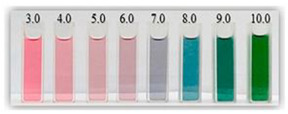

| Corn starch | Intelligent packaging film | pH = 1–10, color variation from pink to purple and blue depending on the pH variations

|

Increase in thickness and water solubility | ↔ | ↔ | [54] |

| Bovine gelatin | Smart packaging film | pH = 1–14 | No effect on thickness and WVP; decease in moisture content; increase in water solubility (alcoholic extract) |

Alcoholic extract: (↔); Aqueous extract: (↑) |

Alcoholic extract: (↑); Aqueous extract: (↔) |

[64] |

| Bovine gelatin | Smart packaging film | pH = 2–12, purple, blue, and finally green at pH 8–12

|

No effect on the thickness | _ | _ | [50] |

| KGM/O-ChNCs | Smart packaging film | pH = 2–12, the color changed from pink–red to green

|

No significant effect on thickness; increase in water solubility and WVP; Decease in light transmittance |

↓ | ↓ | [52] |

| Hydroxypropyl methylcellulose | Intelligent packaging film | pH = 2–9

|

No effect on thickness; changes in the light barrier properties |

↓ | ↑ | [51] |

| CBO-loaded chitosan capsules | Smart packaging film for fish | pH range of 6–8

|

No effect on the thickness | ↓ | ↑ | [53] |

| Bacterial cellulose nanofibers | Intelligent packaging film | pH = 2–10, color change in the BCA label at pH 2 and 3 (dark red) and pH 4–10 (dark violet), and in the BCDA label from bright red to dark blue

|

Increase in moisture absorption | ↓ | ↑ | [57] |

| Dual-modified cassava starch | Intelligent packaging film | pH = 2–12

|

_ | _ | _ | [68] |

| Chitosan/oxidized–chitin nanocrystals | Smart packaging film for hairtail and shrimp | pH = 3–10, color variations (red–pink–purple–blue–green) in different pHs

|

No effect on thickness; significant decrease in WVP, OP values, and light transmittance |

↓ | ↑ | [39] |

| Chitosan/PVA | Intelligent packaging film for pork meat | pH = 1–13 (pH = 1 (reddish color), pH ≈ 6 (purple), pH = 7–8 (blue), pH = 9 (sea green), pH ≈ 12 (yellow–green))

|

_ | ↑ | ↑ | [65] |

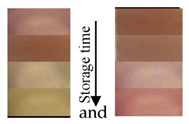

| Cationic guar gum film/hydroxyethyl cellulose | Smart packaging film for pork meat and soybean milk (SBM) | Pork for 72 h and SBM for 18 h

|

Decrease in WVP and OP; decrease in light transmittance |

(↑) with ≤3% RCA, (↓) with 5% RCA |

(↑) with ≤3% RCA, (↓) with 5% RCA |

[63] |

| Chitosan/corn starch | Intelligent packaging film for fish fillet | pH = 2–13 Blue after 16 h, and yellow after 72 h at room temperature |

No significant change in WVP | _ | _ | [45] |

| PVA | Intelligent electrospun nanofiber mat for packaging date fruit (rutab) | pH = 2–12 At 25 °C: after 72 h (color altered slightly), 72–96 h (violet and purple), after 96 h (purple) At 5 °C: color completely changed to purple after 12–20 days

|

Increase in moisture adsorption | ↓ | ↑ | [58] |

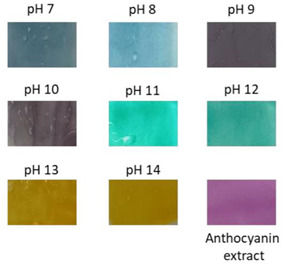

| PEGDA/LCNF | Intelligent hydrogel | pH = 1–14 pH = 7–14

|

No significant change in moisture adsorption | _ | _ | [69] |

| Cellulose acetate | Intelligent electrospun Nanofiber for health monitor | pH = 1–14

|

_ | _ | _ | [70] |

| Zein | Intelligent electrospun fiber | pH = 1–14

|

_ | _ | _ | [71] |

| PVA/NaAlg | Intelligent electrospun nanofiber for wound dressing | pH = 4–10

|

_ | _ | _ | [72] |

| PVA/sodium carboxymethyl cellulose | Intelligent packaging film for pork meat | Pork for 24 h

|

Increase in thickness | ↓ | ↑ | [55] |

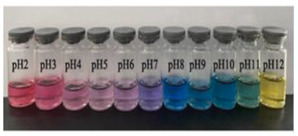

| Cellulose acetate | Intelligent packaging film | pH = 1–12 (red color at pH 1–2, pink at pH 3, violet at pH 4–6, blue at pH 7–8, green at pH 9–11, and yellow at pH 12)

|

Increase in thickness and OP; decrease in light transmittance |

↓ | ↑ | [47] |

CBO: clove bud oil, PVA: polyvinyl alcohol, SBM: soybean milk, KGM: konjac glucomannan, ASKG: Artemisia sphaerocephala Krasch. gum, O-ChNCs: oxidized chitin nanocrystals, CMC·Na: carboxymethyl cellulose sodium, BCA: BC–anthocyanin, BCDA: BC-diluted anthocyanin, PEGDA: poly (ethylene glycol) diacrylate, LCNF: lignocellulose nanofiber, NaAlg: sodium alginate, NA: not affected, WVP: water vapor permeability, and OP: oxygen permeability. The arrows ↑, ↓ and ↔ indicate significant increase and decrease and no significant change, respectively. All figures/tables used in this table are reprinted with permission from their publishers where needed.