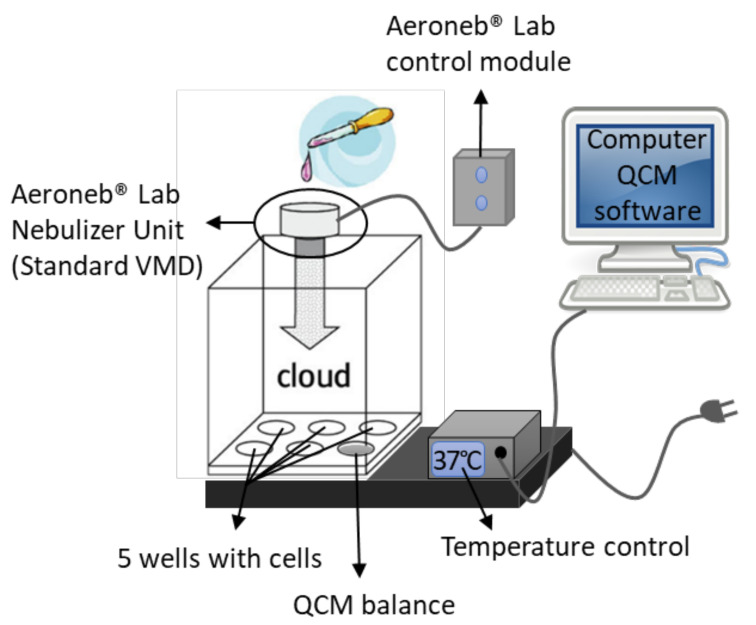

Figure 1.

Schematic of the VITROCELL® 6 Cloud device. The stainless-steel base module of this device comprises 5 electrically heated wells in which 13 mL of medium and the inserts are placed. The temperature in the wells is maintained at 37 °C. A sixth well contains a quartz crystal microbalance (QCM) for cell-delivered dose measurements with a resolution of 10 ng/cm2, at a sampling rate of 1 Hz and a manufacturer-specified zero noise level of 20 ng/cm2 (VITROCELL® Systems, Waldkirch, Germany), measurements are analyzed and visualized using the computer QCM software. The upper part of the device is a 2250 cm polycarbonate removable exposure chamber pierced on the top with a hole to place the nebulizer. The nebulizer system is composed of the Aeroneb® Lab Nebulizer Unit, Standard VMD and a Aeroneb® Lab Control Module (Aerogen Inc., Galway, Ireland). The nebulization relies on a perforated piezoelectrically controlled vibrating mesh to generate acoustic pressure waves releasing liquid droplets at a high frequency (128 kHz). This nebulizer is constituted of a palladium mesh pierced with ca. 1000 holes, releasing between 0.3 and 0.8 mL of liquid per minute through the holes, resulting in a stream of droplets precisely controlled for size by the diameter of the apertures (4–6 m droplet diameter for the Standard VDM nebulizer).