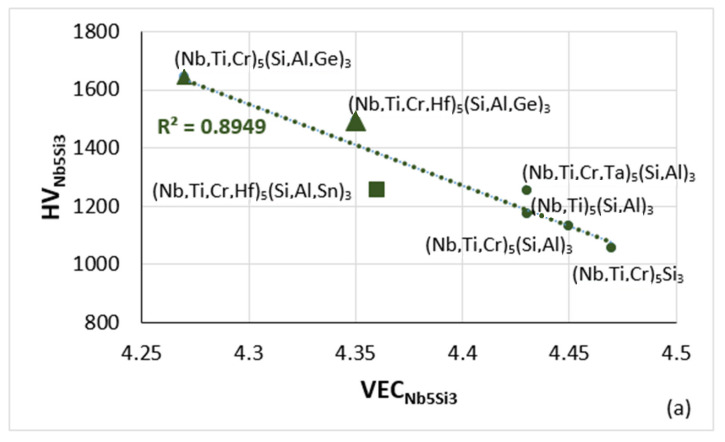

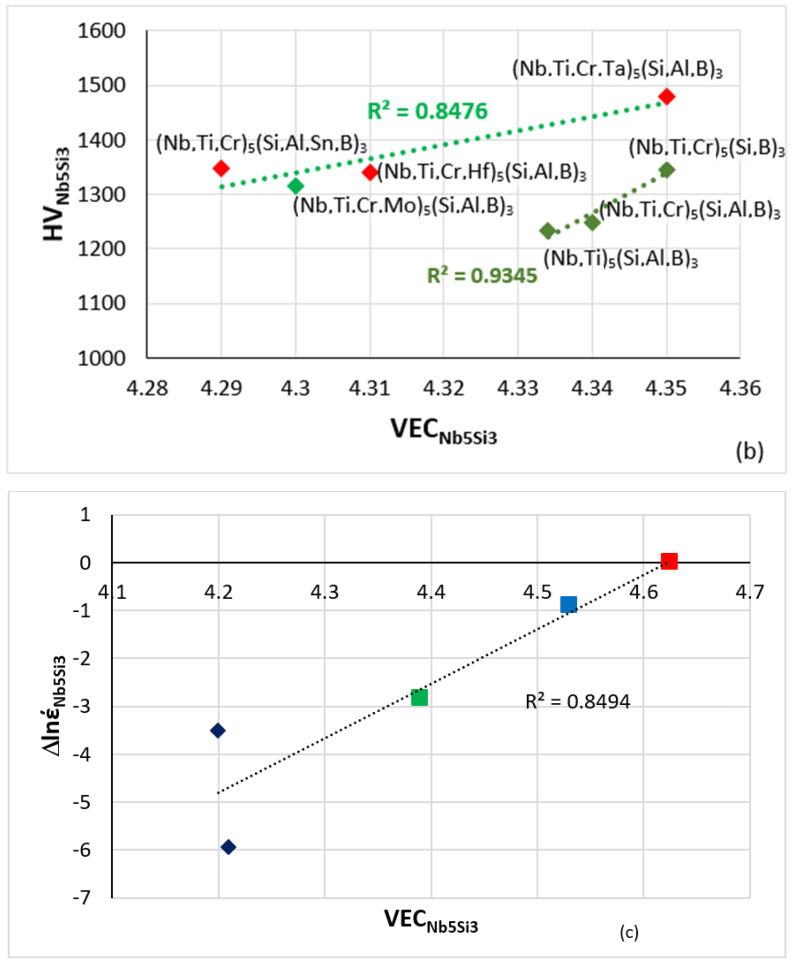

Figure 5.

(a,b) Vickers hardness of alloyed Nb5Si3 versus VEC. (a) Silicide in boron-free RM(Nb)ICs, triangles and square in RM(Nb)ICs with Ge or Sn addition, respectively (b) Silicide in boron containing RM(Nb)ICs (diamonds), of which those that also are RM(Nb)ICs/RCCAs are shown in red. (c) Change of creep rate (Δlnέ) versus VEC at 1200 °C and 150 MPa with reference the binary Nb5Si3, data from [1,9]. Colours in (c): tetragonal unalloyed Nb5Si3 (red square), tetragonal (Nb,Ti)5Si3 (blue square), tetragonal (Nb,Ti,Cr,Hf)5(Si,Al,B)3 (green square) and hexagonal (Nb,Ti)5Si3 and (Nb,Ti,Hf)5Si3 (blue diamonds). The more negative Δlnέ is, the higher is the creep rate compared with αNb5Si3 at the said conditions.