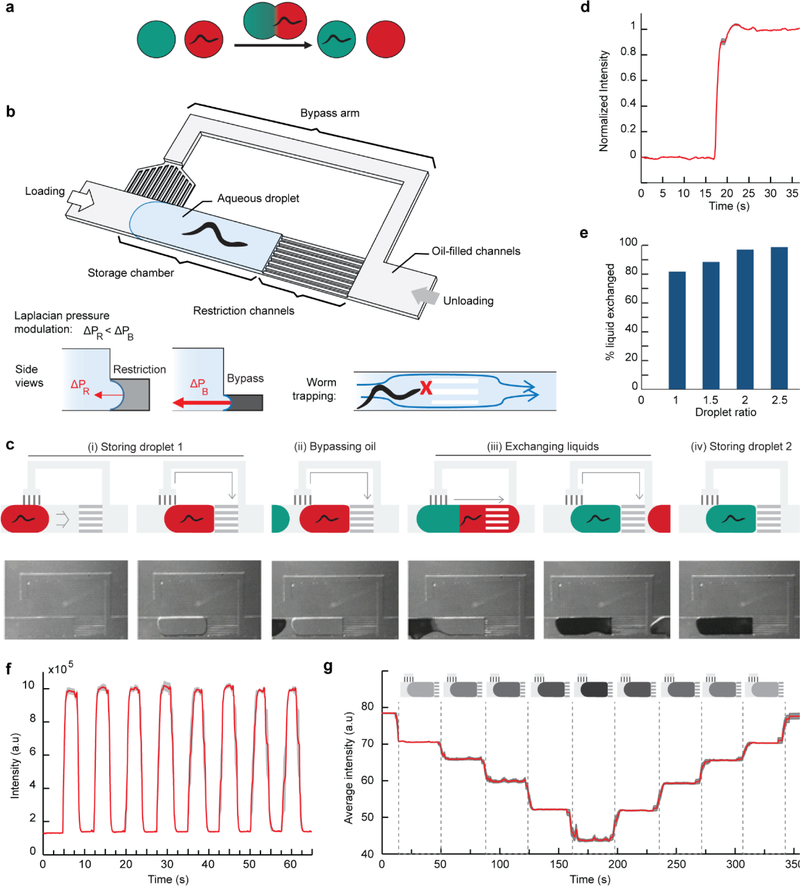

Figure 3.

Dynamic control of the chemical environment of an animal in a droplet. (a) The liquid exchanger allows swapping the whole chemical environment of an animal encapsulated in a droplet with another droplet. (b) Schematic of the unit. Left insert: The difference in channel cross-sections induces a modulation of the Laplacian forces at the droplet interfaces in the restriction channels and bypass channels. Right insert: The cross-section of the restriction channels is smaller than the animal, preventing its escape. (c) Step-by-step operation of the device for one exchange (i-iv). Oil flow is from left to right. (i) As the red droplet enters the chamber, the oil flow is deflected through the bypass. The pressure on the red droplet decreases and the red droplet remains in the chamber. (ii) The oil spacer flows through the bypass as the green droplet approaches. (iii) Liquid exchange operates as the bypass is blocked and the oil pressure increases to push the merged droplet through the restriction channels. (iv) The green droplet is now trapped in the chamber in a situation similar to the red droplet in step (i). One can perform multiple exchanges by repeating steps (ii-iv) or switch the oil flow from right to left to unload the chamber and start a new assay from step (i). (d) Liquid exchange dynamics. (e) Characterization of liquid exchange efficiency when varying the volume of the second droplet, here reported as the droplet ratio (length of the second droplet over the length of the first droplet, i.e., the chamber length). (d-e) were performed with a single-arm bypass device, Nbypass channels = 12, and Nrestriction channels = 9. (f,g) Generation of chemical profiles previously impossible to achieve in droplets: (f) Square signal achieved using an alternation of droplets with and without dye (n= 5 trials; droplet ratio: 2; grey curves are average ± SEM). (g) Linear up and down gradient obtained via a train of droplets with different dye concentration (n= 10 trials; droplet ratio: 3.2; grey curves are average ± SEM).