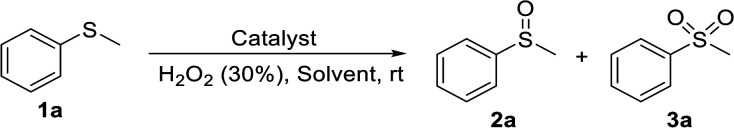

Optimization of reaction conditionsa.

| |||||

|---|---|---|---|---|---|

| Entry | Catalyst | Conv.b (%) | 2a Sel.b (%) | 3a Sel.b (%) | UR (%) (H2O2) |

| 1c | None | 3 | 99 | 0 | 2.5 |

| 2c | TeW6Cu | 89 | 86 | 14 | 64 |

| 3c | Te2W8Cu2 | 99 | 96 | 4 | 80 |

| 4d | Te2W8Cu2 | 91 | 96 | 4 | 73 |

| 5e | TeW6Cu | 99 | 7 | 93 | 74 |

| 6e | Te2W8Cu2 | 99 | 1 | 99 | 79 |

| 7f | Te2W8Cu2 | 99 | 21 | 79 | 79 |

Reaction conditions: 1a (0.5 mmol), catalyst (0.17 mol%), solvent (1 ml).

Yields determined by GC analysis using 1-adamantanol as an internal standard.

H2O2 (30%) (1.2 equiv.), MeOH or EtOH (1 ml), 8 h.

H2O2 (30%) (1.0 equiv.), MeOH or EtOH (1 ml), 8 h.

H2O2 (30%) (2.5 equiv.), MeCN (1 ml), 6 h.

H2O2 (30%) (2.0 equiv.), MeCN (1 ml), 8 h. UR = utilization rate.