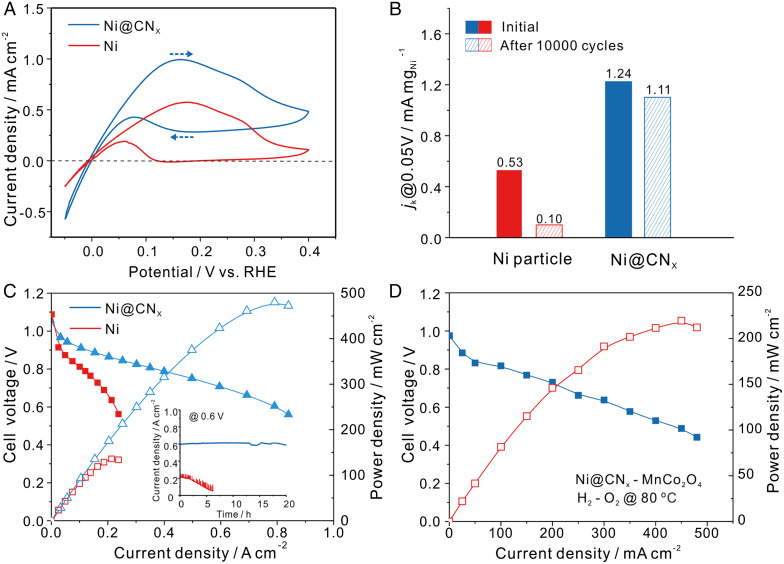

Fig. 2.

The electrocatalytic performance of Ni@CNx compared with Ni NPs (Ni). (A) RDE profiles recorded at a rotation rate of 2,500 rpm and a scan rate of 5 mV/s. Ni@CNx electrocatalysts (blue) and Ni NPs (red). Dashed arrows reflect the positive- and negative-going directions in the CV scans. (B) Current density of Ni@CNx and Ni NPs measured at 0.05 V after 10,000 potential cycles from −0.1 to 0.4 V versus RHE. (C) Single-cell performance with anode catalysts of Ni@CNx and Ni NPs with a loading of 15 mgNi/cm2 and cathode catalysts of 60 wt % Pt/C with a loading of 0.4 mgPt/cm2. The Inset describes a stability test at a constant potential polarization at 0.6 V. (D) APEFC performance using Ni@CNx as anode (15 mgNi/cm2) and 80 wt % MnCo2O4 (1.5 mgoxide/cm2) cathode catalysts. Red and blue curves represent power density and cell voltage as a function of current density, respectively. Fuel cell operation conditions in Fig. 2 C and D: cell temperature of 80 °C, gas back pressure of 0.2 MPa on both sides of the cell. Fully humidified H2 and O2 were fed at a flow rate of 500 mL/min. Open and closed data points in C and D represent the cell voltage and power density, respectively.