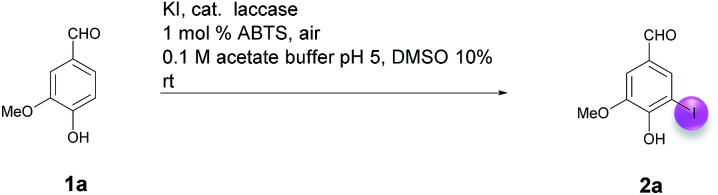

Optimization of amount of KI, air supply, amount of enzyme and reaction timea.

| |||||

|---|---|---|---|---|---|

| Entry | Equiv. KI | Air | t [h] | Add. enzyme [U], [h] | Yield 2a (%) |

| 1 | 20 | 1 atm | 48 | 180 (44) | 65 |

| 2 | 5 | 1 atm | 48 | 180 (44) | 72 |

| 3 | 3 | 1 atm | 48 | 180 (44) | 85 |

| 4 | 1.5 | 1 atm | 48 | 180 (44) | 77 |

| 5 | 1 | 1 atm | 48 | 180 (44) | 11 |

| 6 | 3 | 1 atm | 48 | 45 (44) | 86 |

| 7 | 3 | 20 mL min−1 | 15 | 45 (5) | 77 |

| 8 | 3 | 20 mL min−1 | 15 | 90 (5) | 85b |

2 mmol 1a were reacted in 90 mL buffer. The yields of 2a refer to isolated yields. Initially, 45 U laccase were added; additional laccase in 3 mL acetate buffer was added during the time given by syringe pump. Substrate in 3 mL DMSO was added by syringe pump during the same time the enzyme was added.

The ratio 2a : 3a was determined by 1H NMR analysis of the crude product (198 : 1).