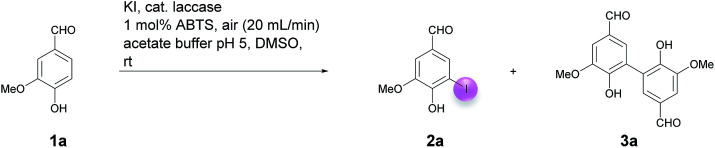

Experiments towards the optimization of chemical yield, selectivity and E-factor of the model reactiona.

| |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Entry | Laccase (U) | Substrate + enzyme addition t (h) | KI (equiv.) | Time (h) | DMSO (vol%) | Buffer (mol L−1) | Buffer vol. (mL) | Isolated yield 2a (%) | 2a : 3a | ΔpH | E-factor |

| 1 | 45 + 90 | 5 | 3 | 15 | 10 | 0.1 | 90 | 85 | 198 : 1 | 31.9 | |

| 2 | 45 + 90 | 5 | 3 | 15 | 10 | 0.1 | 45 | 62 | 38 : 1 | 19.5 | |

| 3 | 45 + 135 | 5 | 3 | 20 | 10 | 0.1 | 45 | 85 | 48 : 1 | 13.9 | |

| 4 | 45 + 225 | 5 | 3 | 20 | 2.5 | 0.1 | 45 | 59 | 20 : 1 | 9.6 | |

| 5 | 45 + 225 | 10 | 3 | 20 | 2.5 | 0.1 | 45 | 63 | 65 : 1 | 8.9 | |

| 6 | 45 + 225 | 10 | 2 | 20 | 2.5 | 0.1 | 45 | 70 | 31 : 1 | 6.6 | |

| 7 | 45 + 90 | 5 | 3 | 20 | 10 | 0.05 | 45 | 64 | 20 : 1 | +2.3 | 18.5 |

| 8 | 45 + 90 | 5 | 3 | 20 | 10 | 0.1 | 45 | 66 | 26 : 1 | +2.2 | 18.3 |

| 9 | 45 + 90 | 5 | 3 | 20 | 10 | 0.2 | 45 | 58 | 98 : 1 | +1.2 | 21.9 |

| 10 | 45 + 90 | 5 | 3 | 20 | 10 | 0.5 | 45 | 43 | 198 : 1 | +0.5 | 33.8 |

| 11 | 45 + 225 | 10 | 2 | 20 | 2.5 | 0.2 | 45 | 77 | 48 : 1 | 6.6 | |

| 12 | 45 + 225 | 10 | 1.5 | 20 | 2.5 | 0.2 | 45 | 68 | 65 : 1 | 7.0 | |

| 13 | 45 + 225 | 15 | 1.5 | 20 | 2.5 | 0.2 | 45 | 67 | 198 : 1 | 7.2 | |

| 14 | 45 + 225 | 15 | 1.5 | 24 | 1.25 | 0.2 | 45 | 77b | 198 : 1 | 4.6 | |

| 15 | 45 + 225 | 10c | 1.5 | 24 | 0 | 0.2 | 45 | 83b | 31 : 1 | 2.9 | |

| 16d | 0 | 15 | — | 24 | 1.25 | 0.2 | 45 | 47d | 198 : 1 | 6.7 | |

2 mmol substrate were reacted. 45 U laccase were added initially, additional laccase and substrate were added separately and simultaneously during the time given via syringe pump. The ratio of 2a and 3a was determined after filtration and drying of the crude product via1H NMR.

Isolated yield after filtration.

Enzyme was added during 15 h via syringe pump and substrate was added manually as a solid.

0.75 equiv. I2, no laccase and ABTS was used.