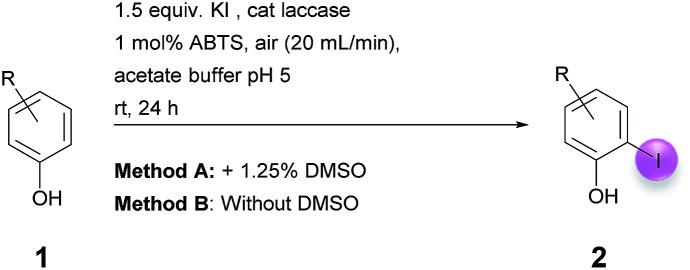

Sustainable iodination of selected substratesa.

| |||||

|---|---|---|---|---|---|

| Entry | 1 | Method | Yield product (%) | 2a : 3a | E-factor |

| 1 | a | A | 77 (2a) | 198 : 1 | 4.63 |

| 2 | b | A | 80 (2b) | 98 : 1 | 4.14 |

| 3b | c | B | 90 (2c) | 198 : 1 | 2.22 |

| 4c | e | B | 90 (2e) | 198 : 1 | 2.55 |

| 5d | i | B | 92 (2i) | 198 : 1 | 2.49 |

| 6 | k | B | 93 (2k) | 198 : 1 | 2.44 |

2 mmol substrate were reacted in 45 mL buffer. Initially, 45 U enzyme were added, additionally laccase (225 U) in buffer (562 μL) was added during 15 h by syringe pump. Method A: substrate in 562 μL DMSO was added by a second syringe pump during the same time the enzyme was added. Method B: substrate was added during 10 h as a solid. The yields refer to yields after filtration and washing of the crude product with water. Ratio of 2a : 3a was analyzed via1H NMR after filtration and drying of the crude product.

72 h reaction time.

255 U laccase were added during 36 h.

48 h reaction time.