Abstract

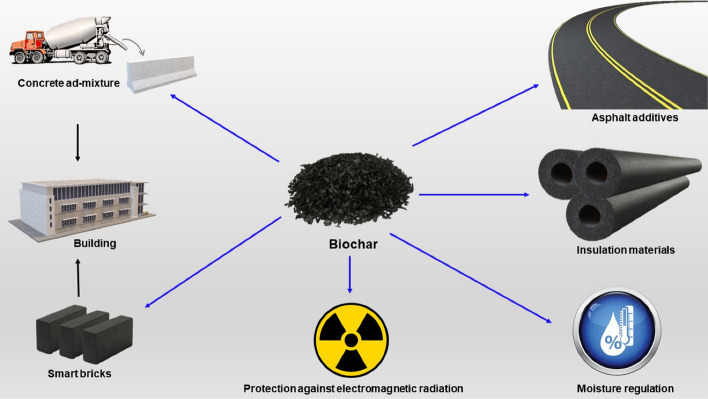

In the context of climate change and the circular economy, biochar has recently found many applications in various sectors as a versatile and recycled material. Here, we review application of biochar-based for carbon sink, covering agronomy, animal farming, anaerobic digestion, composting, environmental remediation, construction, and energy storage. The ultimate storage reservoirs for biochar are soils, civil infrastructure, and landfills. Biochar-based fertilisers, which combine traditional fertilisers with biochar as a nutrient carrier, are promising in agronomy. The use of biochar as a feed additive for animals shows benefits in terms of animal growth, gut microbiota, reduced enteric methane production, egg yield, and endo-toxicant mitigation. Biochar enhances anaerobic digestion operations, primarily for biogas generation and upgrading, performance and sustainability, and the mitigation of inhibitory impurities. In composts, biochar controls the release of greenhouse gases and enhances microbial activity. Co-composted biochar improves soil properties and enhances crop productivity. Pristine and engineered biochar can also be employed for water and soil remediation to remove pollutants. In construction, biochar can be added to cement or asphalt, thus conferring structural and functional advantages. Incorporating biochar in biocomposites improves insulation, electromagnetic radiation protection and moisture control. Finally, synthesising biochar-based materials for energy storage applications requires additional functionalisation.

Keywords: Climate change mitigation, Biochar applications, Carbon sink, Biochar-based fertilisers, Environmental remediation, Energy storage, Biochar in construction

Introduction

Carbon sequestration is the process of capturing atmospheric carbon and storing it in a stable form for extended periods. In comparison with the other carbon removal technologies addressed in the literature, biochar has demonstrated great promise in various ways. This encompasses the technological feasibility, scalability possibilities, carbon removal costs, carbon stability and permanence, verification and monitoring, as well as the benefits associated with the various possible carbon sink applications (Fawzy et al. 2020). Carbon capture and storage via biochar production is technologically viable and has the potential to be commercially feasible, particularly given the current state of the carbon sink economy (Osman et al. 2020).

Carbon sequestration via biochar production is a relatively simple concept. During plant growth, plants take up atmospheric carbon via photosynthesis, and the carbon is stored within the plant structure for as long as the plant exists. When the plant dies, however, the natural decay process returns the carbon to the atmosphere, thus completing the natural carbon cycle. The synthesis of biochar disrupts the carbon cycle by converting it to a stable form that can withstand degradation, hence avoiding emissions of greenhouse gases back to the atmosphere (Qambrani et al. 2017; Brassard et al. 2016). Combining photosynthesis and pyrolytic conversion enables the creation of an effective carbon removal system. Biochar production on a large scale should eventually affect the atmospheric carbon balance by lowering atmospheric carbon concentrations.

To produce stable biochar that is resistant to degradation and can remain stable in potential reservoirs for hundreds or thousands of years, it is necessary to select feedstocks carefully and optimise processing conditions in order to meet reservoir-specific requirements while achieving the highest attainable stability (Fawzy et al. 2021). Additionally, this must be achieved in the most sustainable way possible. While biomass waste is a priority to be utilised for reducing potential emissions and boosting the circular economy, the value and impact of fast-growing speciality crops should not be underestimated, provided they are grown sustainably. If specialised feedstocks are cultivated, the land, water, and nutrient resources used should not directly conflict with food production systems. In general, eligibility of feedstocks must be determined for certification purposes. Additionally, the thermochemical conversion process should be energy efficient, and any pyrolytic gases or waste heat generated should be re-used within the process to minimise emissions (EBC 2012a). Fossil-based energy should be excluded from the manufacturing process and used sparingly in agriculture and transportation, where necessary.

Furthermore, the final application of the biochar is critical to its sustainability as a carbon sink and should be undertaken as sustainably as possible while following regulatory and technical requirements. Biochar can be used as a carbon sink in various applications if they are not related to energy production. Furthermore, the biochar must not be subjected to thermal degradation or oxidisation during its service life or at termination (Schmidt et al. 2019a). Herein, we critically review and evaluate the academic literature on various biochar-based carbon sink applications, covering agronomy, animal farming, biological process stimulation such as anaerobic digestion and composting, environmental remediation, civil infrastructure, and finally, energy storage, where the main objective is to promote atmospheric carbon removal while facilitating enhanced utilisation opportunities and secured carbon storage. While biochar can be used in a variety of applications and cascaded value chains, the ultimate storage reservoirs for biochar are soils, civil infrastructure, and landfills. However, despite optimising biochar production to satisfy application-specific requirements, carbon stability should continue to be the most essential attribute for biochar to fulfil its sequestration purpose once finally applied to such reservoirs for extended periods.

Agronomy

The literature has a wealth of information on the long-term storage of biochar in the terrestrial carbon pool via agricultural and forest soils. The soil is the largest terrestrial carbon sink, and the impact of biochar application on soils has gained considerable academic and commercial interest over the last two decades. It has been reported that if biochar is produced under the proper conditions to achieve carbon stability, it can be safely stored in soils for centuries.

Numerous studies have reported the persistence of carbon in soils. Wang et al. conducted a meta-analysis of 24 studies to determine the stability of biochar in soil. The researchers conducted a meta-analysis of biochar decomposition and calculated its mean residence time using 128 observations. The degradation rates varied significantly according to the feedstock type, processing conditions, duration of the experiment, and soil clay content. The results demonstrated that the labile carbon pool has a mean residence time of 108 days, and the stable carbon pool has a mean residence time of 556 years, with each pool accounting for 3 and 97% of the total carbon, respectively. This clearly shows that only a small percentage of biochar is bioavailable and that a substantial portion contributes to long-term carbon sequestration. When applied to soils, biochar is subjected to biotic, abiotic, and indirect stresses, all of which affect the rate of mineralisation (Wang et al. 2016).

Highly stable carbon should withstand such stresses, and as previously discussed, this depends on the feedstock and processing conditions. Apart from its potential for carbon sequestration, biochar has been reported to have many agronomic benefits. Biochar application, in general, is argued to have a significant effect on soil quality and fertility. Additionally, improvements in nutrient cycling have been reported, as well as an increase in water and nutrient retention. In theory, the proper application of biochar can significantly impact crop productivity, water and nutrient efficiency, and soil health. Additionally, it has been reported that biochar application can aid in the reduction of greenhouse gas emissions such as carbon dioxide, methane and nitrous oxide from soils (Fawzy et al. 2020), though the reported results are inconsistent (Semida et al. 2019; Xiao et al. 2019). The benefits outlined above are due to the biochar's effect on soil physical, chemical and biological properties such as porosity and bulk density, soil water dynamics, acidification, interaction with soil organic matter and inhibition of priming effect, and stimulation of soil microbial activity and dynamics (Oni et al. 2019; Dai et al. 2020; Tenic et al. 2020).

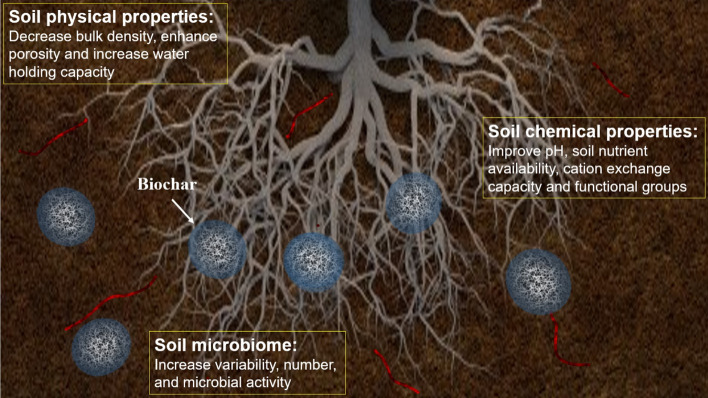

Figure 1 depicts the impact of biochar application on soil physical, chemical and biological properties. While the results generally indicate positive effects, there have been instances where biochar application resulted in negative outcomes. In general, the results reported in the literature are dependent on the type of feedstock used and the production conditions, the amount of biochar applied, the type of soil used, the specific cropping system, and cultivation management techniques deployed (Fawzy et al. 2020; Fawzy et al. 2021; Maraseni 2010; Purakayastha et al. 2019).

Fig. 1.

Biochar has a significant role in improving the chemical, physical, and microbiological properties of soil. Among the chemical properties of soil that can be improved are pH, nutrient availability, cation-exchange capacity and functional groups. Additionally, soil physical properties such as bulk density, porosity, and water holding capacity properties can be improved. Moreover, soil biological properties are enhanced by the addition of a significant amount of bioavailable nutrients, which improve the variety, number, and activity of soil microorganisms

Biochar-based fertilisers

There is disagreement in the literature regarding the use of biochar as a fertiliser, with some arguing for biochar as a fertiliser (Kumar et al. 2021a), while others downplay its utility for this purpose (Gelardi and Parikh 2021; Ippolito et al. 2020). As previously discussed, the discrepancy could be explained by the difference in climate and soil conditions, the feedstocks used for biochar production, or by the processing conditions employed, as it is well established that the nutrient content of biochar is dependent on the raw materials used and the conditions of heat treatment (Tomczyk et al. 2020).

In general, biochar contains a small amount of key nutrients (Ippolito et al. 2020). This would require large amounts of biochar to be added to the soil, between 10 and 50 t ha−1, depending on the soil and biochar characteristics. This imposes an economic burden on the farmer, thereby limiting its use (Chunxue et al. 2015; Jin et al. 2019). Additionally, biochar additions greater than 50 t ha−1 have a detrimental effect on the soil microbial community, impairing its fertility. Moreover, it inhibits plant germination and early growth in the soil when applied at such high rates (Joseph et al. 2021). Furthermore, nutrients are released into the soil during the initial days following the addition of biochar (Zhao et al. 2016), which reduces the plant's efficiency in utilising these nutrients, thereby affecting the crop's productivity and quality.

Thus, biochar is frequently used as a soil amendment rather than a fertiliser, to develop the physical and chemical properties of the soil, while low addition rates (1 t ha−1) have been used as a nutrient carrier to increase the efficiency of fertiliser use and reduce nutrient losses (Joseph et al. 2021). If, however, biochar is used as a fertiliser, its nutrient content is typically supplemented with a source of nutrients such as chemical or organic fertilisers. Additionally, as discussed in the following section, biochar can be coated with a variety of materials to facilitate the slow release of these nutrients.

Chemical fertilisers are critical in modern agriculture, and their importance grows as the population continues to expand. Nonetheless, the plant's efficiency in using it is low, usually around 30–35%, resulting in economic and environmental consequences (Li et al. 2019a; Liu et al. 2019a). As a result, scientists are working to develop new ways to maximise the benefits of chemical fertilisers while minimising their adverse effects on the environment and financial costs to farms. In this context, biochar-based fertilisers, a process that combines traditional fertilisers and biochar as a carrier, have emerged as an important topic of agricultural research (Li et al. 2019a; Liu et al. 2019b). The following sections explore the potential for using biochar as a nutrient carrier, preparation techniques, and discusses the impact of using biochar-based fertilisers on agriculture and the environment.

Biochar-based fertiliser preparation techniques

Numerous techniques for preparing biochar-based fertilisers have been discussed in the literature, including mixing, impregnation, co-pyrolysis, and encapsulation/coating. This section will explore each of these approaches.

Mixing

Biochar can be mixed with conventional fertilisers such as compound fertilisers containing nitrogen, phosphorus, and potassium, urea fertilisers, poultry manure, compost, and organic fertilisers prior to or during crop cultivation. Additionally, other additives, such as starch, clay, and alginate, which act as binders, can be used in predetermined proportions to create biochar-based fertilisers (Adekiya et al. 2020; Kulczycki et al. 2020; Puga et al. 2020a). After mixing, the nutrient-rich biochar can be ground to a consistent particle size and then granulated or pelletised. This is to minimise transportation costs, facilitate handling, and prevent the loss of biochar powder due to strong winds or heavy rain (Yu et al. 2021a; Shin and Park 2018).

Impregnation

Impregnation is the process of adding nutrients in solution form to biochar over a specified period and at a specified rate. This facilitates the sorption of such nutrients onto the surface and pores of the biochar, and the nutrient-enriched biochar is then dried (Sim et al. 2021). Common nutrients in this process are nitrogen (Liu et al. 2019b; Chen et al. 2018a), phosphorous (Gwenzi et al. 2018), and potassium (Chandra et al. 2020; Khan et al. 2021a). A recent study reported that after undergoing pyrolysis using agricultural waste, the synthesised biochar was impregnated with macro and micronutrients (Lateef et al. 2019). The results indicated that the biochar nanocomposite had a neutral pH and a porous structure of 55.9 nm, indicating that it was capable of nutrient adsorption. Additionally, salt index, slow-release column, water absorbance, and retention studies indicated that the synthesised biochar nanocomposite has a high potential for use as a nano-fertiliser.

Co-pyrolysis

Previously, biochar was treated with a source of nutrients, either by mixing it into the biochar or by adding the nutrient solution directly to the biochar. However, in this case, nutrients are added to the biomass in the form of a solid substance (Zhao et al. 2016; Lustosa Filho et al. 2017) or a solution (Chen et al. 2020a) and the biomass is then pyrolysed in the presence of such nutrients, a process referred to as co-pyrolysis. Co-pyrolysis of biomass with phosphorous sources has been proposed as a solution to developing improved biochar-based fertilisers with a stable form of carbon and a slow nutrient release mechanism (Zhao et al. 2016; Lustosa Filho et al. 2020). Furthermore, An et al. (2020) reported co-pyrolysis of biomass (cotton straw), with nutrients such as potassium phosphate and bentonite under microwave irradiation, as a novel strategy for synthesising improved quality biochar-based slow-release fertilisers.

Coating and encapsulation

While biochar-based fertilisers have the potential to reduce nutrient loss and increase soil water retention, scientists are focusing their efforts on promoting sustainable nutrient release. Recently, three methods for enhancing the sustained release mechanism have been developed, with the primary goal of reducing nutrient leaching and increasing nitrogen use efficiency. The first approach, either biochar alone or in combination with another material, is used to coat conventional fertilisers such as urea (Jia et al. 2020; Mikos-Szymańska et al. 2019; Chen et al. 2018b). The second technique involves coating the biochar with another material, such as organic matter. Hagemann et al. (2017a) stated that they coated the inner (pores) and outer surfaces of biochar with nutrient-dense organic matter, which resulted in extraordinary nutrient and water retention.

The third method is referred to as integrated co-pyrolysis and coating. In this scenario, biochar is co-pyrolysed with chemical fertilisers and then coated with another material such as a polymer or biodegradable biofilm (An et al. 2021a, b). In the coating methods described, the more hydrophobic groups in the membrane and the greater its thickness, the fewer nutrients are released into the soil, resulting in less fixation, leaching, or volatilisation in the soil. Thus, the appropriate amount of hydrophobic substance and the appropriate membrane thickness must be determined to ensure that the plant receives an adequate supply of nutrients (An et al. 2021b; Azeem et al. 2016).

Biochar engineering methods for enhanced performance

Pristine biochar has some limitations due to its physicochemical properties, such as a negatively charged surface, a small specific surface area, and a deficiency of acidic functional groups (Yang et al. 2019a), which confines its application to adsorbing anionic nutrients, such as nitrate and phosphate. Therefore, biochar is modified to overcome the barriers that prevent it from being used for a particular purpose. Currently, research on biochar modification for fertiliser production is insufficient. However, it is possible to benefit from biochar modification methods for other purposes such as pollutant removal and adapt these methods to suit the modification of biochar for biochar-based fertiliser production.

Biochar-based fertiliser production requires the development of certain characteristics of pristine biochar for it to be suitable for use as a fertiliser. For example, increasing the amount of potassium and ammonium carried by the biochar, introducing new types of nutrients such as phosphorous and nitrate anions, and making the surface of the biochar more hydrophilic to facilitate the adsorption of nutrients and the subsequent exchange with the soil aqueous solution when added to the soil. Additionally, the pores in the biochar must be larger than the size of the nutrient ions and charged appropriately in order for them to adsorb on the biochar. These desired biochar properties must be developed through modifications to the material's physical properties, such as its specific surface area and pore structure characteristics, as well as its chemical properties, such as its surface functional groups. Physical and chemical methods are generally employed to modify biochar. Tables 1 and 2 illustrate the biochar modification methods proposed for producing engineered biochar-based fertilisers, where such methods can effectively enhance biochar properties to produce an effective fertiliser. However, it should be noted that practical experiments must be conducted to verify the feasibility of producing plant-nutrient-compatible fertilisers.

Table 1.

Physical techniques of biochar modification include steam or gas activation, ultrasonic treatment and ball milling

| Modification type | Method of modification | Modification agent | Process of modification | Key findings | References |

|---|---|---|---|---|---|

| Physical | Steam/gas activation | Steam | Biochar was heated from 25 °C under nitrogen flow and preheated 500–800 °C steam | Surface area increased from181 to 322 m2 g−1 | Shim et al. (2015) |

| Steam | For 45 min, biochar samples were treated with 5 mL min−1 of steam |

Reduced equilibrium time from > 24 h to ∼ 4 h Improved adsorption capacities of sulphamethazine up to 98% |

Rajapaksha et al. (2016) | ||

| Carbon dioxide |

Biochar was treated to a system that ran on carbon dioxide (CO2) at a rate of 0.15 L min−1 The temperature was raised at a rate of 10 °C min−1 until 900 °C, then held at 900 °C for 60 min |

Created a consistent pore distribution Developed total pore volume of 0.0014–0.0468 cm3 g−1 Increase surface area from 0.2 to 80.5 m2 g−1 |

Franciski et al. (2018) | ||

| Carbon dioxide and ammonia |

The biochar was heated gradually to 500–900 °C, using a heating rate of 10 °C min−1, with nitrogen (99.99%); at 400 ml min−1 purging After the temperature reached the desired value, nitrogen was replaced by carbon dioxide (99.999%); 100 ml min−1, or ammonia (99.999%); 80 ml min−1 or CO2–ammonia (CO2 = 100 ml min−1 and ammonia = 80 ml min−1) |

Increased surface area significantly to about 627.15 m2 g−1 from 224.12 m2 g−1 Introduced nitrogen-containing groups into the biochar |

Zhang et al. (2014a) | ||

| Ultrasonic treatment | Ultrasonic sonicator |

Water bamboo biochar was exposed to ultrasound (frequency of 20 kHz and electric power of 65 W) for different irradiation times Air saturated de-ionised water was employed in all tests A water bath was employed to maintain the water temperature at 25 °C |

The surface area and pore volume increased from 56.3 to 141.2 m2 g−1 and 0.013 to 0.039 cm3 g−1, respectively Ability of adsorption increased upon 3.486 mg g−1 of reactive black 5 |

Nguyen et al. (2021) | |

| Low-frequency ultrasound |

Modification of biochar was achieved under 20 kHz low power ultrasound irradiation Radiation exposure periods are 30 s, 1, and 3 min |

Exfoliated the biochar’s graphitic clusters Created new micropores Opened the blocked pores Enhanced the functionalisation efficiency Boosted the adsorption capacity |

Chatterjee et al. (2019a) Chatterjee et al. (2018) |

||

| A probe-type ultrasonic vibrator |

Biochar dispersion was prepared by vibrating 3 g of biochar in 80 mL water in a 100 mL glass beaker, placed in a cooling bath After sonication, the aqueous suspension was passed through a 500 μm sieve The sieved suspension was then centrifuged to keep the nanosized particles suspended in the supernatant based on Stokes Law The suspension was placed in a 50 mL glass centrifuge tube, centrifuged at 3500 g for 24 min, and then repeated to extract biochar-NPs |

Increased the surface area of biochar from 0.76 m2 g−1 and its nano- form showed the largest surface area of 36.39 m2 g−1 Pore volume was significantly lower than their macro- counterparts |

Oleszczuk et al. (2016) | ||

| Ball milling | Planetary ball mill machine | Biochar was placed in a planetary ball mill machine (PQ-N2, Across International, New Jersey, USA) within agate jars (500 mL) with balls (diameter of 6 mm, 180 g in each jar) and operated at 300 rpm in ambient air and with rotation direction altered every 0.5 h | The specific surface areas of the ball milled-biochar were all greater than that of unmilled biochar | Lyu et al. (2018a) |

The surface area, total pore volume, introduced nitrogen-containing functional groups, and adsorption are the most important properties that are enhanced via physical modification. As a result of these modifications, biochar's ability to function as a fertiliser is improved

Table 2.

Chemical techniques of biochar modification include acid and alkali treatments

| Modification type | Modification method | Modification agent | Process of modification | Key findings | References |

|---|---|---|---|---|---|

| Chemical modification | Acid treatment |

Phosphoric acid Nitric acid |

Biochar samples were modified by adding concentrated phosphoric acid or concentrated nitric acid or phosphoric acid and nitric acid Acid equivalence corresponded to 0.25 cmol Kg−1 |

Water solubility of biochar increased Nitrate and phosphate groups increased Improved plant growth in calcareous soils |

Sahin et al. (2017) |

|

Sulphuric acid Nitric acid Hydrochloric acid |

Tea-waste biochar samples were modified by the addition of 10% sulphuric acid, 69% nitric acid, 5 M hydrochloric acid to 10 g of Tea-waste biochar at (50–60 °C) |

Oxygenated surface functional groups have a notable contribution to cation-exchange capacity, especially at high pH At basic pH, the functional moieties are deprotonated, and surface complexation is promoted For biochar-300, the highest cation-exchange capacity was observed when it was subjected to nitric acid modification, and for biochar-500, the highest value was observed in hydrochloric acid modification Low point of zero charge values allow for the sorption of cationic species under mildly acidic conditions through electrostatic interactions |

Peiris et al. (2019) | ||

|

Hydrochloric acid Sulphuric acid Hydrogen peroxide |

The biochar modification was performed with a Soxhlet extraction apparatus in which 200 cm3 of liquid was used. The modifiers were added into a 250 cm3 round bottom pyrex flask with 10 g of biochar and reacted at room temperature with a water condenser for 24 h – The modified biochar was washed with de-ionised water and dried in an oven at 105 °C |

Provided a relatively high ammonium cation sorption capacity Oxygen-containing groups on the biochar surface increased The inorganic minerals were washed Polarity increased Aromaticity decreased |

Wang et al. (2020a) | ||

| Alkali treatment |

Potassium hydroxide Potassium carbonate Sodium hydroxide Sodium carbonate |

The biochar was impregnated with several alkali agents at a mass ratio of 3:1 (alkali chemical/biochar) The chemically activated biochar was then heated under nitrogen at different temperatures 600, 700, 800 and 900 °C for 3 h Afterwards, the biochar sample was cooled, washed with hydrochloric acid and distilled water and oven-dried at 105 °C |

The introduction of oxygenated groups on biochar surface An increase in the surface basicity The temperature to beyond 700 °C was not effective in improving the nitric oxide uptake capacity The use of alkali agents improved the nitric oxide adsorption capacity of the modified biochar by 3.3–3.5 times that of the parent biochar |

Anthonysamy et al. (2021) | |

| Potassium hydroxide |

Biochar was soaked in 30% potassium hydroxide at room temperature for 8 h Furthermore, it was washed with purified water to neutrality and dried at 105 °C |

Pore size was mainly mesoporous Surface area increased from 194.77 to 712.07 m2 g−1 |

Liu et al. (2020a) |

The most important properties of biochar that are enhanced via chemical modification include oxygen-containing functional groups, cation-exchange capacity, pore size, and surface area. As a result of these modifications, biochar's ability to function as a fertiliser is enhanced

Additionally, it is worth considering the trade-off between activating biochar and achieving long-term carbon sequestration. The issue related to physical activation through thermal treatment is the excessive loss of carbon as well as high energy consumption during high-temperature activation, which compromises the carbon sequestration potential of the modified biochar. Furthermore, the chemical activation route may impose an environmental burden due to the use of chemicals. In conclusion, we recommend further research on biochar activation in order to establish the optimal conditions for biochar production and activation that balance carbon stability and applicability within a broad range of agricultural and environmental applications. Additionally, conducting life-cycle analysis to determine the impact of biochar modification on the environment and carbon sequestration potential is critical.

Physical modification methods

In general, the most frequently used physical methods for biochar modification are steam/gas activation, ultrasonication, and ball milling. Physical modification increases the surface area and total pore volume of the biochar, as well as facilitates the incorporation of nitrogen-containing groups and enhances the adsorption capacity. As a result of these modifications, biochar's ability to function as a fertiliser is enhanced.

The impact of steam/gas activation on biochar properties is influenced by the activation temperature, the mass ratio of steam or gas to biochar, and the duration of the activation. In general, as more carbon atoms are removed from the surface of biochar, the volume/radius of pores and surface area increase in line with the steam temperature and treatment time (Sajjadi et al. 2019a). Furthermore, despite the fact that steam is a weak oxidant, steam/gas activation is used to augment biochar surfaces with oxygen-containing functional groups (e.g. carboxylic, carbonyl, ether, and phenolic hydroxyl groups), thereby increasing the surfaces' hydrophilicity (Ahmed et al. 2016). While steam/gas activation is simple, it consumes a lot of energy due to the high temperature required. As a result, microwave activation, ultrasonication, plasma treatment, and electrochemical modification strategies have recently grown in popularity as low-cost methods for increasing biochar adsorption capacity (Bushra and Remya 2020).

Ultrasonic treatment of biochar results in beneficial chemical and physical changes, including carboxylation, hydrogenation, increased reaction rates and increased internal surface area (Sajjadi et al. 2019a). This type of treatment requires significantly less energy than conventional activation methods. Cavitation induced by ultrasound waves exfoliates and disintegrates the regular shape of the biochar's graphitic oxide layers, cleans smooth surfaces, and increases the porosity and permeability of the carbonaceous structure of the biochar (Sajjadi et al. 2019b). The literature reports that biochar had become nanoscale after being exposed to ultrasound waves, resulting in a significant increase in surface area (Oleszczuk et al. 2016). However, increasing its frequency for an extended period may result in the destruction of the biochar structure and pores. As a result, proper conditions must be adopted for this strategy to be effective (Nguyen et al. 2021).

Ball milling is a simple and common approach used for enhancing the properties of biochar. Ball milling is a highly effective method for reducing the size of biochar to a nanoscale (less than 100 nm in size), which is referred to as nanobiochar (Wang et al. 2017a; Liu et al. 2018a). Nanobiochar has gained popularity in recent years due to its ability to combine the benefits of nanotechnology and biochar technology, as well as its beneficial chemical and physical properties. The rotational speed, ball-to-power mass ratio, and milling duration all have an effect on the final nanobiochar's particle size and surface energy (Ramanayaka et al. 2020).

Nanobiochar is distinguished from pristine biochar by its substantially larger surface area, graphitic character and significantly negative zeta potential (Oleszczuk et al. 2016). Additionally, nanobiochar produced at low temperatures, such as 300 and 400 °C, followed by ball milling, has a surface area range of 5.6–47.2 m2 g−1, whereas nanobiochar produced at high temperatures, such as 450 and 600 °C, has a much larger surface area range of 342–430 m2 g−1 (Ramanayaka et al. 2020; Lyu et al. 2018a). Ball-milled biochars had finer particle sizes of 140–250 nm vs 0.5–1 mm for unmilled biochar, and a higher concentration of oxygen-containing functional groups of 2.2–4.4 mmol g−1 vs 0.8–2.9 mmol g−1 for unmilled biochar (Lyu et al. 2019). However, due to the mobility of nanobiochar, off-site migration of pesticides and other pollutants along the soil profile may pose a risk to groundwater (Wang et al. 2017a).

Chemical modification methods

Chemical modification is becoming more prevalent, most likely because it increases the surface area and enhances porosity of the biochar (Sahin et al. 2017). As a result, numerous chemical methods have been proposed to modify biochar, including acid and alkali treatment. Increasing oxygen-containing functional groups, enhancing cation-exchange capacity, pore size, and surface area are the most important properties of biochar that are modified chemically. As a result of these modifications, biochar's ability to function as a fertiliser is enhanced.

Acid treatment of biochar is one of the most used chemical strategies for removing impurities such as metals, increasing the number of mesopores, and increasing oxygen-containing functional groups such as hydroxyl, carboxyl, and others, thereby increasing its hydrophilicity and, ultimately, its adsorption capacity for polar adsorbates. Acids such as sulphuric, hydrochloric, nitric, and phosphoric acid, as well as weak acids such as oxalic and citric acid, are frequently used in acid treatment to modify biochar (Yang et al. 2019a; Deng et al. 2020; Wang and Wang 2019). Alkali modification or chemical reduction refers to the process of activating the surface of biochar with reducing agents such as sodium hydroxide, sodium carbonate, potassium carbonate (Anthonysamy et al. 2021), and potassium hydroxide (Anthonysamy et al. 2021; Liu et al. 2020a). Furthermore, alkaline materials containing hydroxide ions or an amino group react with the functional groups on the surface of biochar, enhancing the sorption of negatively charged species (Ahmed et al. 2016), such as nitrate and phosphate ions, which are critical in the field of plant nutrition. Additionally, alkali treatment significantly alters the specific surface area and porosity of biochar (Liu et al. 2020a; Kumar et al. 2021b).

Mineral–biochar composite fertilisers

Mineral–biochar composites are produced by combining minerals such as zeolite, clay, and layered double hydroxide minerals with biochar to form composites with unique and useful properties. Then, as shown in Fig. 2, chemical fertilisers are added with the mineral–biochar composite to create mineral–biochar composite fertilisers (Wang et al. 2021a; Zhao et al. 2021a; Premarathna et al. 2019; Lesbani et al. 2021; Azimzadeh et al. 2021).

Fig. 2.

Steps of the production of a mineral-biochar composite fertilisers. Mineral-biochar composites are initially created by combining minerals like zeolite (O1), clay (O2), and layered double hydroxide (O3) with biochar. Additionally, chemical fertilisers are combined with the synthesised mineral-biochar composites (O4) to form mineral-biochar composite fertilisers (O5)

Zeolite-biochar composite fertilisers

Zeolites are crystalline hydrated aluminosilicates with pores comparable to those of molecules in frameworks based on extensive three-dimensional oxygen ion networks (Matsuda 2018). Zeolites exhibit extraordinary physical and chemical properties, including mechanical strength and high adsorptive ability. These attributes make them extremely useful in various applications, including agriculture and environmental protection. As a result, scientists developed zeolite–biochar composites to combine the benefits of zeolite and biochar, where biochar is more biologically and chemically stable compared to the original biomass resources used, in addition to serving as a source of long-term stored carbon in soil (Zhao et al. 2021a; Pavelic et al. 2018; Hina et al. 2015). According to Hina et al. (2015), biochar made from pine chips is a more effective ammonium sorbent than pine bark for wastewater treatment but is approximately 40% less effective than commercially available zeolite. This demonstrates the importance of using a zeolite–biochar composite as a carrier for chemical fertilisers. Another study reported that following a 90-day incubation period, the application of zeolite–biochar composites increased the soil pH from 5.60 to 8.33 and cation-exchange capacity from 6.5 to 61.28 cmol kg−1, indicating the possibility of using this composite as a fertiliser in combination with chemical fertilisers, in addition to stabilising pollutant metals such as cadmium, lead, and arsenic (Zheng et al. 2020).

Clay-biochar composite fertilisers

Clay minerals are members of the hydrous layer aluminosilicate family of minerals, which are distinguished by their layered structures composed of polymeric silica tetrahedral sheets connected to octahedral sheets (Bibi et al. 2016). Additionally, clay is distinguished by its ability to be modified to customise its properties for specific applications such as nutrient or pollutant adsorption (Abbas et al. 2017a). Furthermore, clay minerals are characterised by their small particle size and high surface-to-volume ratio. Moreover, they are readily available and inexpensive materials with exceptional chemical and mechanical stability (Wal et al. 2021). As a result, clay and biochar can be integrated to produce a composite that achieves the desirable properties of both materials.

In a study conducted by Liu et al. (2019b), a clay-biochar composite fertiliser was prepared via incorporating urea, bentonite and polyvinyl alcohols into biochar through hydrothermal synthesis. This synthesis resulted in interactions between biochar, urea, bentonite, and polyvinyl alcohols, contributing to the final products' water retention and controlled release properties. The cumulative release of nitrogen was reported to be 61.3% within 28 days when incubated in water and 54.6% within 98 days when incubated in soil, demonstrating the favourable controlled-release properties of the clay-biochar composite fertiliser. This behaviour could be explained by the fact that nutrients interact with composites in various ways. For example, ammonium can bind to biochar through Van der Waals adsorption, electrostatic attraction, the reaction of ammonium with acidic functional groups to form amides and amines, and π–π electron donor–acceptor interactions. Another study found that adding clay and iron oxide to biochar increases infiltration and the formation of clay and metal oxide nanostructures within the pores of the biochar, which promotes redox reactions that can have a significant effect on nutrient availability and uptake in plants, as well as the growth of beneficial microorganisms that improve the rhizosphere's health (Rawal et al. 2016).

According to Chen et al. (2017a), an effective composite of montmorillonite and biochar was produced. Both biochar and montmorillonite contributed to the texture and structure of the surface, resulting in a varied surface and an array of adsorptive sites. Ammonium adsorption was attributed in part to ammonium surface adsorption on montmorillonite and biochar, and in part to ammonium intercalation within the montmorillonite interlayer space. Phosphate adsorption, on the other hand, was governed by electrostatic attraction and ionic bonding on the montmorillonite-biochar composite.

Layered double hydroxide-biochar composite fertilisers

Environmentally friendly and biocompatible layered double hydroxide clays, also known as anionic clays, have stimulated researchers' interest due to their superior ion exchange capacity and ability to intercalate anions, as well as their high adsorption capacity and surface area characteristics (Chatterjee et al. 2019b). These characteristics are critical because certain nutrients, such as nitrates and phosphates, are available to plants as anions. Zhang et al. stated that through weak interactions, layered double hydroxide–biochar composites adsorbed nutrients such as ammonium and nitrate (i.e. van der Waals force electrostatic attraction and hydrogen bonding). As a result, nutrients are gradually released, while immobilised pollutants such as heavy metals are strongly bound via more compact mechanisms such as ionic and coordinate bonding (Zhang et al. 2018a). According to Azimzadeh et al. (2021), phosphorous-loaded layered double hydroxide-biochar significantly increased available phosphorous, corn shoot and root dry matter, and phosphorous uptake when compared to control.

Application methods and rates

Biochar can be used in a single application and will provide benefits for many years due to its stability. Additionally, because biochar matures in soil and its interaction with soil varies over time, it is unnecessary to use biochar at each crop sowing. However, field data are currently unavailable to determine whether applying a large dose of biochar initially is more beneficial or whether yearly administrations at lower rates are preferable (Oelbermann et al. 2020).

Researchers identified a variety of techniques for applying biochar and fertilisers to the soil, including spot, ring, broadcast and incorporate (Yeboah et al. 2020). In addition to these methods, biochar can be applied directly or in combination with agricultural residues, compost, manure, and seed (Murtaza et al. 2021). Numerous studies have discovered that biochar application methods significantly affect soil characteristics. For instance, of the three distinct biochar application techniques (spot, ring, and broadcasting), the spot and ring approaches achieved the greatest improvement in observed parameters when compared to the control. The spot was the most effective method, followed by the ring, and finally the broadcasting method. As a result, when using biochar to enhance the agronomic performance of cowpea in a moderately acidic sandy soil, the application technique is critical for achieving benefits such as increased growth and yield, as well as soil fertility (Yeboah et al. 2020).

Another study reported that adding biochar and compost to the soil as a spot treatment reduced broomrape attacks on fava bean plants. Not only was a suppressive effect against broomrape achieved, but also the economic yield and protein content of fava bean were maintained, demonstrating the robust effect of spot placement of biochar and compost on fava bean sustainability in broomrape-infested areas (Saudy et al. 2021). Xia et al. (2022) stated that the optimal treatment was 100 mg kg−1 nitrogen fertiliser applied with biochar in deep placement modes, with a maximum nitrogen use efficiency of 46.23%. Additionally, biochar may facilitate the growth of corn in acidic soils by improving poor soil (low pH and low fertility).

Impact on agriculture and the environment

In addition to being a source of plant nutrients, biochar-based fertilisers can be critical in amending and enhancing certain soil physical and chemical properties. This is particularly applicable in soils with unfavourable characteristics for agriculture, such as sandy soils and highly weathered soils, such as those found in the tropics, as illustrated in Table 3, as well as having an effect on microbial biomass (Li et al. 2020a).

Table 3.

Effects of biochar application on soil properties

| Properties of soil | Type of soil | Period of field experiment | Type of feedstock | Suitable application rate of biochar | Effect of biochar application | References |

|---|---|---|---|---|---|---|

| Bulk density | Sandy loam Alfisol | 2 years | Hardwood | 30 t ha−1 | Decreased by 74.7% | Aruna et al. (2020) |

| Porosity | Chinese black soil | 3 years | Corn straw | 31.5 t ha−1 | Increased | Jin et al. (2020) |

| Moisture content | Haplic Luvisol | 3 years | Pinewood | 50 t ha−1 | Increased | Medyńska-Juraszek et al. (2021) |

| pH | Acid soil | 120 days | Wood | 20 t ha−1 | Decreasing soil acidity | Shetty and Prakash (2020) |

| Cation-exchange capacity |

RedLatosol (clayey texture) Red-Yellow Latosol (medium texture) |

9 months | Coffee husk (Pyrolysed at 350 °C) | 20% |

Doubled the soil cation-exchange capacity (from 19.1 to 40.4 cmolc kg−1) Increased the soil cation-exchange capacity by ten-fold from 2.3 to 23.1 cmolc kg−1 |

Domingues et al. (2020) |

| Erosion resistance | Highly weathered soil | 105 days | Waste wood of white lead trees | 5% (wt/wt) | Reduced soil loss by 64% | Jien and Wang (2013) |

This includes bulk density, porosity, moisture content, pH, cation-exchange capacity and erosion resistance. The results demonstrate the critical role of soil type, biochar type, and application rate in improving these properties

They can also benefit the environment, particularly slow-release biochar-based fertilisers, by reducing nutrient leaching and the high need for access to water sources, as well as by reducing greenhouse gas emissions, which have a detrimental effect on the ecosystem and human health. However, some studies (Knoblauch et al. 2021; Kavitha et al. 2018) have indicated that adding pristine biochar may negatively affect nutrient availability and crop productivity, which must be considered when preparing these fertilisers. These are largely determined by the properties of the biochar used (Gonzaga et al. 2018), and the characteristics and location of the soil (Puga et al. 2020b; Jeffery et al. 2017), as well as the rate at which the biochar has been added (Chrysargyris et al. 2020; Yooyen et al. 2015). As a result, applying biochar and biochar-based fertilisers to agricultural soils requires a thorough assessment of their effects on soil characteristics and crop production, which should ideally be conducted under field conditions with actual application rates.

Biochar-based fertilisers are distinguished from conventional fertilisers by their ability to gradually release nutrients into the soil, resulting in a significant reduction in nutrient loss due to leaching or volatilisation and an increase in nutrient utilisation efficiency (Puga et al. 2020b; Ndoung et al. 2021). Researchers reported a 12% increase in nitrogen utilisation efficiency when biochar-based nitrogen fertilisers were compared to urea alone in a study evaluating the effect of biochar-based nitrogen fertilisers on tropical soils. As a result, the average yield of corn increased by approximately 26%. The slow release of nitrogen from the biochar-based fertiliser was associated with an increase in nitrogen use efficiency and corn production (Puga et al. 2020b). Liao et al. demonstrated that biochar-based controlled-release nitrogen fertilisers successfully increased oilseed rape yield (16.6%) and nitrogen-use efficiency (58.79%) by gradually releasing nitrogen and modulating the abundance of functional microbes via increased soil nitrification and decreased denitrification when compared to a urea-only treatment. Biochar-based controlled-release nitrogen fertilisers increased soil nitrate, which increased rape nitrogen absorption and utilisation efficiency, thereby enhancing oilseed rape development and grain production (Liao et al. 2020).

Another study found that when biochar was enriched with phosphorus in a 50:50 (w/w) ratio using both the hot and cold methods, there was a significant increase in soil extractable phosphorus and total nitrogen, as well as high organic content, crop growth, yield, and modulation, when compared to the control and the other treatments (Wali et al. 2020). Abbas et al. (2017b) stated that biochar was applied at a rate ranging from 1 to 10% of the urea fertiliser weight in each treatment. The results indicated that using 10% biochar in combination with the recommended dose of urea increased plant height, spike length, number of tillers, number of spikelets per spike, grain yields, biomass yield, harvesting index, nitrogen concentration and uptake in grain and straw, and nitrogen agronomic efficiency by 6, 11.1, 32, 55.3, 5.4, 38, 19, 9, 19, and 26%, respectively, in comparison with the treatment using the recommended rate of nitrogen without the addition of biochar.

On the other hand, several field studies demonstrated that applying biochar to agricultural soil significantly reduced nitrate, potassium, phosphorous, magnesium, sodium, and calcium leaching (Vijay et al. 2021). Li et al. (2019a) reported that tobacco stems were pyrolysed to produce biochar. It was then added to the compound fertiliser at four concentrations of 0%, 3%, 9%, and 15% (w/w). In comparison with the control, the leaching loss of total nitrogen from the soil decreased by 8.36, 6.72, and 6.45%, respectively, and the loss of total potassium from the soil decreased by 9.18, 9.31, and 11.82% in the 3, 9, and 15% biochar with fertiliser treatments, respectively. However, because phosphorus has a low mobility in the soil profile, biochar-based fertilisers had little effect on phosphorus leaching. Additionally, biochar-based fertilisers increased ammonium, available phosphorous, and available potassium immobilisation in the soil profile.

Nitrous oxide has been estimated to have a global warming potential of 298 and 11.9 times that of carbon dioxide and methane, respectively (Domeignoz‐Horta et al. 2018). Additionally, nitrous oxide is a persistent greenhouse gas that can remain in the atmosphere for 100 years, with atmospheric nitrous oxide concentration increasing by 0.2–0.3% annually (Grutzmacher et al. 2018). Nitrous oxide is produced during the incomplete conversion (nitrification) of ammonium to nitrate by ammonium-based nitrogen fertilisers (Dawar et al. 2021).

Recently, biochar has been proposed as a means of mitigating climate change by reducing nitrous oxide emissions. In this regard, Grutzmacher et al. (2018) stated that when ammonium nitrate was used in combination with biochar, nitrous oxide emissions were reduced sevenfold in sewage sludge biochar treatment. Additionally, the fertiliser emission factor decreased with biochar amendments, ranging from 0.01 to 0.08% of the nitrogen emitted as nitrous oxide, demonstrating biochar's potential to reduce fertiliser-induced nitrous oxide emissions, with sewage sludge biochar mitigating 87% of soil-fertiliser emissions. According to another study, nitrous oxide emissions were significantly reduced by 31.4–39.9% when a fertiliser was applied in combination with biochar, compared to chemical fertiliser application alone at 200 kg nitrogen ha−1, and the nitrous oxide emission factor of the applied nitrogen was reduced from 1.36% when only chemical fertiliser was applied to 0.71–0.85% when fertiliser plus biochar application was used. These findings suggest that applying nitrogen fertiliser and biochar at an appropriate rate are viable strategies for reducing field-scale nitrous oxide emissions (Niu et al. 2017).

Summary

This section demonstrated the potential utilisation of biochar within agronomic applications. Agriculture is the most common biochar-based carbon sink application discussed in the literature, where a variety of benefits can be extracted in addition to serving as a long-term carbon reservoir. However, the impact on soil and crops is inconsistent and generally depends on the type of feedstock used and processing conditions employed for biochar production, the specific cropping system, and management practices. While biochar is not a source of nutrients in and of itself, its use as a nutrient carrier has garnered substantial attention in the scientific literature.

Overall, our analysis shows that biochar-based fertilisers, a process that combines traditional fertilisers with biochar as a nutrient carrier, are a very promising and value-adding route for biochar utilisation within agronomy. Several preparation strategies were explored, where various modification treatments were proposed for enhancing the biochar’s performance. It is critical to understand the impact of such treatments on the carbon stability of the biochar as well as the overall environmental footprint, and thus, detailed life cycle assessments need to be carried out to adequately determine the biochar’s carbon removal potential. In general, the utilisation of biochar as a nutrient carrier is a highly recognised strategy, which can facilitate many agronomic benefits while allowing for long-term storage in soils. However, proficiency in biochar preparation is essential for synthesising a product that can be successfully used.

Animal farming

Biochar value can be maximised if applied within animal farming prior to being used in various cascaded applications and final long-term storage in soils. This section will explore the various areas where biochar can be utilised in the animal farming industry and will critically assess the merits and challenges highlighted in the literature. Furthermore, the technical requirements specific to this application will be presented.

Utilisation of biochar as a feed additive

Recently, several scholars have investigated the effects of co-feeding biochar with animal diets on cattle, poultry, pigs, and fish (Abakari et al. 2020; Al-Azzawi et al. 2021; Schubert et al. 2021; Goiri et al. 2021; Kalus et al. 2020a). Co-feeding with biochar increased milk production by 3.43% and protein–fat content by 2.63–6.32%, respectively, and reduced enteric methanogens in Australian dairy cattle by 30% (Al-Azzawi et al. 2021). Additionally, co-feeding with 2.5% biochar increased daily feed intake of laying hens, improved laying performance by 6%, and enhanced shell solidity and thickness by 10% and 6%, respectively (Kalus et al. 2020a).

Similarly, Goiri et al. discovered that co-feeding broilers with biochar at a 30 g kg−1 diet concentration increased daily weight gain, average body weight, and reduced feed conversion ratios compared to non-co-fed groups (Goiri et al. 2021). Furthermore, it has been shown to increase the survival and growth of aquatic fish (Mabe et al. 2018). Moreover, co-feeding with biochar reduced Gallibacterium anatis and Campylobacter hepaticus pathogens in poultry as a result of biochar's inherent adsorption properties (Willson et al. 2019). Consequently, biochar may be a viable alternative to antibiotics in the animal husbandry sector (Man et al. 2021). The unique properties of biochar may help maintain gut microbiota (methanogens) within its porous structure, thereby reducing greenhouse gas emissions from ruminants (Al-Azzawi et al. 2021; Eger et al. 2018; Mirheidari et al. 2020), which are the primary source of agricultural greenhouse gaseous emissions, and thus positively influencing global climate change. Additionally, farm production may be increased as a result of decreased chemical fertiliser use, which arises from improved animal excreta that maximise soil fertilisation quality (Joseph et al. 2015; Kalus et al. 2019).

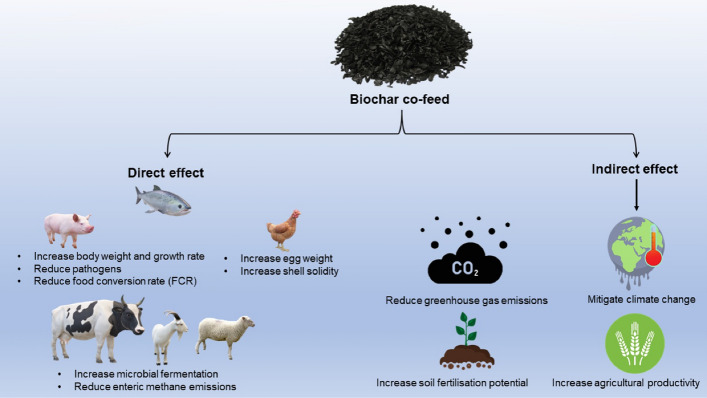

In conclusion, research indicates that co-feeding with biochar can improve animals' production, growth, immunity, and blood profile; reduce pathogens and enteric methane generation by accelerating microbial fermentation, and improve overall agricultural productivity; however, research in this field is scarce. As such, this section focusses on the effects of various biochar substrates used as supplements (biochar co-feed) on farm animals, fish, and poultry, while also highlighting scientific gaps and areas for future research. The overall effects of co-feeding biochar are depicted in Fig. 3.

Fig. 3.

Advantages of co-feeding animals with biochar. The direct effects of adding biochar to animal feed include increased body weight and growth rate, improved microbial fermentation, pathogen reduction, and decreased enteric methane emissions. Additionally, an indirect positive impact can be generated by improving the quality of fertilisation and reducing greenhouse gas emissions, which would help to mitigate climate change

Regulations for adopting biochar as a feed supplement

The feedstock used to produce biochar for co-feed supplements undergoes pyrolysis at temperatures ranging from 350 to 1100 °C (Man et al. 2021; Das et al. 2021). This thermal treatment, combined with the specific properties of the underlying biomass feedstock, results in biochar with a unique physicochemical structure, such as an exceptionally large surface area capable of capturing and holding minute particles, that serves as a habitat for microorganisms, as well as adsorbs undesirable compounds. Additionally, the produced biochar contains a variety of surface functional sites and mineral components that have a variety of agricultural and environmental applications (Das et al. 2020a, b). As previously discussed, the overall effect of the produced biochar is entirely dependent on the biomass type, temperature, and residence time. However, biochar used for feed applications must comply with certain requirements issued by official authorities. For instance, the European food safety authority regulates certain specifications for feed-grade biochar pursuant to specific feed regulations [Commission regulation (EC) No 178/2002 and 834/2007] (EBC 2012b).

The European biochar certification foundation, commonly referred to as EBC, is a well-known non-governmental organisation that establishes standards for sustainable biochar production in Europe. In general, various classes of biochar are promoted, based on their intended use, the unique characteristics of the produced biochar, and its toxicant content. It is critical to note that certified biochar that is permitted for use as a feed additive must be made from untreated and natural biomass (EBC, 2012b). Table 4 summarises the specific characteristics required for certification of feed-grade biochar following European biochar certification (EBC, 2012b).

Table 4.

Biochar standards for obtaining the European certificate of feed-grade biochar

| Criteria | Biochar co-feed criteria values |

|---|---|

| Polycyclic aromatic hydrocarbons | Less than 4 mg kg−1 |

| Carbon content | More than 80% |

| Heavy metals | Arsenic: Less than 2 mg kg−1 |

| Lead: Less than 10 mg kg−1 | |

| Cadmium: Less than 1 mg kg−1 | |

| Mercury: Less than 0.1 mg kg−1 | |

| Benzo-a-pyrene | Less than 25 µg kg−1 |

| The dioxin-like polychlorinated biphenyls | A start value of 0.35 ng TE kg−1 |

| Polychlorinated dibenzo-p-dioxins and dibenzofurans along with dioxin-like polychlorinated biphenyls | Less than 1.25 ng TE kg−1 |

| Polychlorinated dibenzo-para-dioxin/ Polychlorinated dibenzofurans | A limit of 0.75 ng TE kg−1 |

| Fluor | Less than 150 mg kg−1 |

| Dry matter, insoluble-, and crude- ashes | Same as standard values imposed by EU regulations for feed |

| Crude protein, crude fat, and crude fibre | 0 g kg−1 due to pyrolysis effect |

| Paint and solvents | Free |

| Contaminants such as plastics, rubber, and electronic scrap | Free |

All parameter values are calculated at 88% (dry matter basis). The various criteria and their values are summarised

Effects of co-feeding biochar on the performance of animals

Food additives, including amino acids, organic minerals, fatty acids, vitamins, and antibiotics, are frequently used in animal farming to enhance the growth operation, productivity, immune status, and protein intake of the animals. Around 90% of biochar produced in Europe is used in agro-environmental activities such as animal husbandry (cattle and poultry farming), crop production, and environmental remediation (Gerlach and Schmidt 2012). Biochar is primarily used as a feed supplement in the animal husbandry industry (Kammann et al. 2017). Biochar's annual use in agriculture is expected to increase by 12.5% over the next 5 years (Man et al. 2021). Feed-grade biochar is primarily added to feed at a rate of 0.1–4.0% of the daily feed intake (Man et al. 2021; O’Toole et al. 2016). As shown in Table 5, adding biochar to feed has the potential to increase feed intake and weight gain (Mirheidari et al. 2020; Sivilai et al. 2018); improve animal health (Bolan et al. 2021; Yıldızlı et al. 2021); facilitate toxin and contaminant detoxification, increase nutrient intake, decrease antibiotic residues, and decrease enteric methane release (Man et al. 2021; Schmidt et al. 2019b; Toth et al. 2016).

Table 5.

Utilisation of biochar as a co-feed in animal production, including a summary of biochar's potential for improving the performance of cattle, sheep, goats, pigs, poultry, and fish, as well as the conditions under which biochar is produced and the raw substrates used

| Animals | Raw substrates | Generation condition | Amount of biochar used | Main influence | References | |

|---|---|---|---|---|---|---|

| Cattle | Rice husks | Gasification > 400 °C | 0.6% of daily feed dry matter |

Increased body weight Reduced methane release |

Leng et al. (2012a) | |

| 1% of daily feed dry matter with 4% rice distiller’s by-product |

Increased weight gain by 15% Reduced feed conversion ratio |

Phongphanith and Preston (2018) | ||||

| 2–8% |

Increased weight gain Reduced feed conversion ratio |

Saroeun et al.(2018) | ||||

| Pine trees | 0.8 and 3% of dry feed matter | 0.8% improved organic matter and fibre digestibility and reduced methane generation | Winders et al. (2019) | |||

| Goats | Rice husks | Gasification > 400 °C | 1% of daily feed dry matter | No influence on digestibility, feed intake, and nitrogen content | Phongpanith et al. (2013) | |

| Walnut shell and chicken manure | Pyrolysis at 550 °C for 3 h | 0.5, 1, and 1.5% of diet dry matter | 1% walnut shell and 1.5% chicken manure biochar increased digestibility, milk yield, and methane emissions | Mirheidari et al. (2019) | ||

| Fibrous biomass | Gasification > 400 °C | 1.1% of daily feed dry matter |

Increased body gain Reduced feed conversion ratio Increased dry matter digestibility Increased nitrogen retention |

Silivong and Preston (2015) | ||

| Sheep | Lodgepole pine and quaking aspen | Pyrolysis > 600 °C | 2% of dry feed matter | Improved dry matter digestibility and intake and volatile acetate production | McAvoy et al. (2020) | |

| Pistachio by-product, walnut shell, and chicken manure | Pyrolysis temperatures (above 550 °C) for 3 h | 1–1.5% |

Improved feed conversion ratio and average daily gain No influence on dry matter intake, volatile fatty acid productions, rumen pH, and rumen protozoa |

Mirheidari et al. (2020) | ||

| Pigs | Bamboo | Pyrolysis > 600 °C | 0.3% of dry feed matter |

Improved weight gain to 17.5% Improved the quality of marketable meat |

Chu et al. (2013a) | |

| Spruce larch, beech, and oak-based biochar and oak | Not mentioned | 2% spruce larch, beech, and oak-based biochar and 2% oak | Improved dry, organic matter, and fibre digestibility | Schubert et al. (2021) | ||

| Poultry | ||||||

| Chicken | Woody green waste | Pyrolysis at 550 °C | 1, 2 and 4% in daily diet |

Increased egg weight by 1, 5 and 4%, respectively – Improved feed conversion ratio by 9, 14 and 12%, respectively |

Prasai et al. (2018) | |

| Eucalyptus hardwood | Lowered poultry pathogens (Campylobacter hepaticus and Gallibacterium anatis) | Willson et al. (2019) | ||||

| Rice husks | Gasification > 400 °C | 1% in daily diet |

– Reduced coliforms and E. coli in litter and faeces – Reduced plasma triglycerides |

Hien et al. (2018) | ||

| Woody waste | Pyrolysis at 550 °C | 4% in daily diet |

– Decreased Campylobacter jejuni – Increased egg weight by 3% – Improved feed conversion ratio by 8% |

Prasai et al. (2016) | ||

| Broiler litter | Gasification | 2–4% | No impact on weight gain and feed conversion ratio | Evans et al. (2017) | ||

| Beechwood | Pyrolysis at 550 °C | 2 and 4% |

– Increased feed conversion ratio by 8% – Increased average body weight by 7% |

Kalus et al. (2020b) | ||

| Poultry litter | Gasification > 400 °C | 5 g kg−1 |

– Increased serum albumin – Decreased serum uric acid, and restored body weight |

Rashidi et al. (2020) | ||

| Pine shaving | Not mentioned | 10–20% per litter |

No influence on performance, health, or litter nutrient content – Improved litter quality – Improved water absorption |

Linhoss et al. (2019) | ||

| Laying hen | Beechwood biochar | Pyrolysis at 550 °C | 1 and 2% |

– Increased daily feed intake 6% increase in laying performance – Increased average egg mass – Increased in shell resistance to crushing and shell thickness – 1.5 and 3% biochar–aluminosilicates–glycerine mixtures reduced and increased daily feed intake, respectively |

Kalus et al. (2020a) | |

| Biochar–aluminosilicates–glycerin mixture | 1.5 and 3% | |||||

| Turkey | Miscanthus grass | Anaerobic conditions at 400 °C | 0, 5, 10, or 20% of bedding |

– Increased body weight – Lowered feed intake – Increased body weight gain – Improved litter quality |

Flores et al. (2021) | |

| Poultry litter | Gasification > 400 °C | 6.2 or 6.9% of the diet |

– Improved pellet quality – Decreased live weight gain – Increased bone mineralisation |

Evans et al. (2017) | ||

| Fish | ||||||

| Japanese flounder (Paralichthys olivaceus) | Bamboo | 0.25, 0.5, 1, 2, and 4% in daily diet |

– Increased weight gain – Increased growth rate – Reduced feed conversion ratio – Increased protein efficiency ratio |

Thu et al. (2010) | ||

| African catfish (Clarias gariepinus) | Palm kernel shell | Microwave pyrolysis | 0 g, 150 g, 300 g, 450 g per tank |

– Decreased ammonia (67%) – Decreased total suspended solids (68%) – Increased nitrogen uptake – Higher growth in lettuce |

Su et al. (2020) | |

| Tilapia (Oreochromis mossambicus) | Water hyacinth | Pyrolysis conditions at 300 °C for 30 min | 0.5 and 1% | Increased fish weight and length (optimum at fishes fed with 1% biochar mixed diet) | Najmudeen et al. (2019) | |

Several scholars have examined the effect of co-feeding with biochar. For example, Castillo-González et al. concluded that adding biochar to ruminal fluid under in vitro conditions improved substrate digestibility (Castillo-González et al. 2014). Similarly, pine biochar was found to improve in vitro nutrient utilisation, protein synthesis, and ruminal fermentation while decreasing methane production (Saleem et al. 2018). Co-feeding with 0.6% biochar made from rice husk enhanced the weight of cattle by 25% when compared to those receiving no diet supplementation (Leng et al. 2012a). Phongphanith and Preston (2018) reported that adding 1% rice husk biochar with probiotic yeast additives to cattle feed improved the diet conversion ratio significantly from 11.5 to 7.9 and increased animal weight by 60%.

Additionally, supplementing 2–8% biochar with urea and molasses improved the feed conversion rate of cattle from 16.4 to 10.7% and increased weight by 43% (Saroeun et al. 2018). Winders et al. (2019) demonstrated that supplementing cattle diets with 0.8% biochar (on a dry matter basis) increased organic matter and fibre digestibility during the growing stage, while quadrupling dry matter intake during the finishing stage, as compared to non-supplemented diets. Furthermore, the authors discovered a decrease in enteric methane generation of 10.7 and 9.6% g d−1 during the growing and finishing stages, respectively. However, adding biochar to an artificial rumen system did not affect total gas and methane production, nutrient disappearance, protein synthesis, rumen microbiota composition, or rumen fermentation (Tamayao et al. 2021).

Similarly, adding pine biochar to the diet of heifers did not affect dry matter intake, nitrogen balance, tract digestibility, or methane production, but reduced protozoa counts and ammonia nitrogen by 0.5 and 1.0%, respectively, when compared to the control diet (Terry et al. 2019). Teoh et al. investigated the effect of daily additions of 400 and 800 mg of hardwood biochar to an in vitro artificial rumen. The addition of biochar had no effect on digestibility, total gas production, propionate, acetate, butyrate, rumen pH, or the rumen bacteria, archaea, or fungal biota. Using 800 mg biochar, on the other hand, reduced methane emissions (Teoh et al. 2019). In conclusion, biochar feed additives have the potential to adsorb gases, contribute to the modification of redox reactions, and act as a habitat for the colonisation of biofilms and the proliferation of microbiota. As a result, biochar co-feeding has the potential to alter rumen fermentation characteristics and reduce enteric methane generation.

Mirheidari et al. investigated the effect of supplementing the diet dry matter with 0.5, 1, and 1.5% walnut shell biochar and chicken manure biochar on rumen fermentation traits in dairy ewes. In comparison with the control, adding 1% walnut shell biochar and 1.5% chicken manure biochar to the in vitro study reduced methane emissions, total volatile fatty acid generation, and ammonia N, while raising pH. In in vivo research, supplementing dairy ewes with biochar at higher concentrations enhanced milk production, milk protein, solids non-fat portion, blood glucose, dry matter, and fibre digestibility rates, and decreased gas emissions (Mirheidari et al. 2019). Silivong and Preston determined that supplementing goats diets with 1.1% biochar increased their weight by 8.9%, improved their feed conversion ratio from 15.5 to 11.4, and improved their digestibility (Silivong and Preston 2015). McAvoy et al. (2020) investigated the effect of co-feeding quaking aspen and lodgepole pine biochar on the digestibility of the diet and overall sheep performance. They discovered that supplementing lambs' diets with biochar boosted digestibility and intake, as well as acetate generation. However, these positive results did not imply considerable improvements in body weight gain or feed conversion efficiency. Similarly, supplementing fattening lambs' diets with 1% pistachio by-product, 1% walnut shell, and 1.5% chicken manure biochar enhanced feed conversion ratio and average daily gain compared to the control. The additives, on the other hand, had no effect on dry matter intake, volatile fatty acid synthesis, rumen pH, or rumen protozoa (Mirheidari et al. 2020).

Schubert et al. investigated diets supplemented with 2% spruce, larch, beech, and oak-based biochar and 2% oak biochar on the performance of growing pigs. The authors discovered that adding biochar to the diet improved dry matter, organic matter, and fibre digestibility, with a maximal increase of 19.8 and 23.8% in crude fibre digestibility, respectively, as compared to the control (Schubert et al. 2021). Sivilai et al. (2018) demonstrated that co-feeding with 1% rice husk biochar enhanced the weight of pigs by 20.1% and the feed conversion ratio by 10.6%. Similarly, it was reported that co-feeding bamboo biochar enhanced unsaturated fatty acids and decreased saturated fatty acids, as well as improved the quality of swine carcasses (Chu et al. 2013b). Co-feeding pigs' diets with 0.3% biochar increased faecal microflora, particularly lactic acid and anaerobic bacteria, while decreasing Salmonella spp. and pathogenic coliform bacteria (Chu et al. 2013c). Chu et al. (2013a) demonstrated that adding 0.3 and 0.6% of bamboo biochar to pig feed decreased triglyceride, blood urea nitrogen, and lactate dehydrogenase levels in the blood while increasing immunoglobulin G, total serum antibody concentration, and Lactobacillus spp. Levels, as compared to the control.

Reducing feed costs, increasing poultry growth, and minimising the adverse environmental impact are recent challenges affecting the poultry industry's sustainability. Kalus et al. (2020b) investigated the effects of co-feeding broiler chickens with biochar on their weight gain and feed conversion ratio. Beechwood biochar (2–4%) and a mixture of biochar, glycerin, and aluminosilicates (3–6%) were added to the broiler's diet. Biochar co-feed reduced ammonia emissions by 17%, raised feed conversion ratio by 8%, and only the lowest doses of biochar increased body weight, whereas larger concentrations had a marginal effect. In the same context, the researchers examined the effects of the same biochar/biochar mixtures on the performance of laying hens. Biochar addition enhanced daily feed intake by 6%, and increased shell resistance to crushing and shell thickness by 10 and 6%, respectively (Kalus et al. 2020a). By adding pine shavings biochar to the turkey's diet by 0, 5, 10, or 20%, body weight increased from 16.72 to 17.0 kg, feed intake decreased from 48.1 to 45.6 kg, and feed conversion ratio improved to 2.20 from 2.31 in the control (Flores et al. 2021). By incorporating chicken litter biochar at a rate of 6.2 or 6.9% into poultry diets, pellet quality was enhanced, feed conversion ratio was decreased, and bone mineralisation was raised due to increased phosphorus and calcium bioavailability (Evans et al. 2015).

Evans et al. reported that supplementing chick diets with 2% broiler litter biochar had no adverse effect on their performance and exhibited superior granulation characteristics and moisture retention capacity (almost 90%) as compared to those formulated with zeolite or bentonite (Evans et al. 2017). Co-feeding with wood biochar increased egg weights and feed conversion ratios in egg-laying poultry as compared to those fed without biochar (Prasai et al. 2017). Biochar's high surface area and porosity make it ideal for pathogen and toxicant control. Prasai et al. (2016) demonstrated that supplementing layer meals with 4% biochar made from wood reduced pathogenic Campylobacter jejuni in the birds' intestine and increased egg weight and feed conversion ratio by 3.0 and 11.7%, respectively. Additionally, co-feeding with biochar can help eliminate toxins from the bird's gut and improve the intestinal flora and its vitality (Gerlach and Schmidt 2012). By feeding chicken with 1% rice husk biochar, plasma triglycerides were diminished and omega-3 fatty acids were increased (Hien et al. 2018).

Co-feeding with biochar in aquaculture has received relatively less attention. It was observed that feeding 0.5% bamboo biochar to Paralichthys olivaceus (juvenile Japanese flounder) enhanced growth rate, weight gain, and feed and protein conversion ratios (Thu et al. 2010). Several authors reported increased body weight, growth rate, and feed conversion ratios following co-feeding with biochar at concentrations ranging from 0.004 to 4% (Moe et al. 2009; Lan et al. 2016; Quaiyum et al. 2014). Najmudeen et al. (2019) examined the effects of co-feeding with 0.5 and 1% water hyacinth biochar on Oreochromis mossambicus fish aquaculture and discovered an increase in fish weight and length, with the greatest increase occurring at 1% biochar content. Abakari et al. (2020) investigated the influence of biochar on the tilapia bio-floc technology system. The researchers discovered no adverse effect on fish growth or performance and observed an improvement in water quality parameters such as total suspended solids when biochar treated fish were used compared to the control.

Biochar functions as a co-feeding additive

Mitigation of enteric methane

Methane, carbon dioxide, fluorinated gases, and nitrous oxides are the primary contributors to greenhouse gas emissions. Around 4 billion ruminants are raised worldwide, including 1.7 billion cattle and buffalos and 2.2 billion sheep and goats (Searchinger et al. 2021). Ruminants have a rumen, which is capable of using cellulose by microbial communities. Through the action of anaerobic bacteria, "enteric methane" is released from the rumen. Enteric methane emissions from domestic animals were estimated to reach 100 million tonnes of carbon dioxide-equivalent in 2018, accounting for more than a quarter of agriculture-related emissions, and is projected to increase by 50% by 2050 (Searchinger et al. 2021). Cattle and buffalos account for over 85% of global emissions, whereas sheep and goats account for 12% (Searchinger et al. 2021; FAO, 2019). Methane is primarily released via eructation, with trace amounts absorbed into the bloodstream and exhaled via the lungs (Danielsson et al. 2017).

There are two types of methane-producing/utilising microbes in the rumen: methanogenic and methanotrophic archaea, which are responsible for enteric methane production. The addition of biochar promotes the growth of methanotrophs, which offers a habitat for methane oxidation within the gut, hence lowering enteric methane emissions in ruminants (Leng et al. 2012b). Another significant factor in lowering enteric methane production is the biochar's ability to adsorb and absorb gases (Danielsson et al. 2017; Pereira et al. 2014). Thus, regular co-feeding of biochar to animals can be an effective strategy for mitigating enteric methane emissions (Leng 2018).

Incubation of biochar with ruminal fluid resulted in a 15% reduction in methane emissions (Leng et al. 2012b). Similarly, enteric methane generation was reduced by 11–17% when 9% biochar (w/w) was added (Hansen et al. 2012). In vivo experiments demonstrated that adding 1% biochar (w/w) to cattle diets reduced methane release by 11–13% (Leng et al. 2012a). Another study reported that adding biochar and combining it with nitrate reduced methane release by 22 and 41%, respectively (Leng et al. 2012b). Additionally, co-feeding cattle with 3.8% biochar (w/w) resulted in a reduction of 12.6 L of methane per animal per day (Khoa et al. 2018). Winders et al. (2019) revealed that adding 0.8% biochar to cattle's diet reduced enteric methane generation by 9.5% and 18.4% g kg−1 dry matter intake, respectively, throughout the growth and finishing stages. Saleem et al. (2018) concluded that adding 0.5% biochar to an in vitro rumen experiment resulted in a 25% reduction in methane production (mg d−1). In conclusion, biochar co-feeding has been shown to effectively reduce enteric methane release from rumens in both in vivo and in vitro experiments.

Elimination of contaminants in livestock

Biochar can remove various pollutants from the environment, including heavy metals, antibiotics, organic chemicals, and microplastics (Gopinath et al. 2021; Wang et al. 2019a). Animals are mostly contaminated by pollutants in their feed and water, such as insects, environmental contaminants, and diverse microbial activity. Rashidi et al. (2020) showed that diets supplemented with 5 g kg−1 biochar made from poultry litter adsorb and restore the body weight of broiler chickens suffering from aflatoxicosis, as well as increase the bird's performance. Co-feeding of layers with 2% biochar (w/w) significantly decreased the incidence of Gallibacterium anatis and Campylobacter hepaticus compared to non-supplemented control diets (Willson et al. 2019). Similar reductions in Campylobacter jejuni were reported in pullet guts co-fed with biochar (Prasai et al. 2016). Biochar's adsorption capacity for contaminants is primarily determined by its specific surface area, functional groups, and sorption characteristics (Oh and Seo 2016).

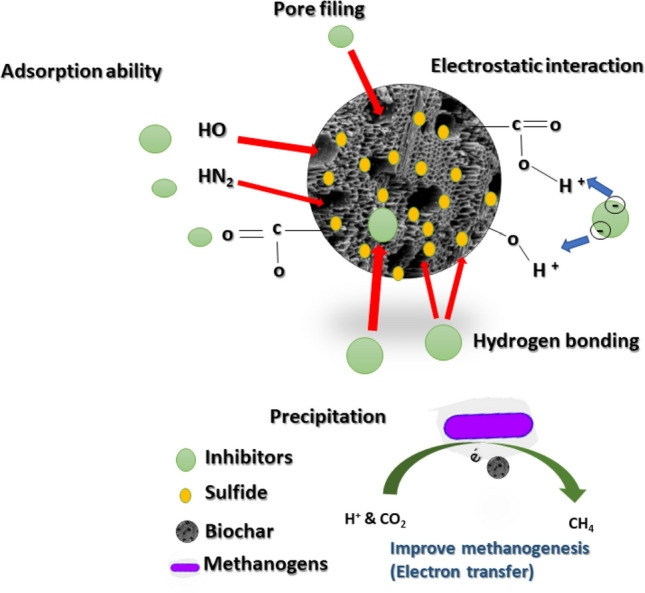

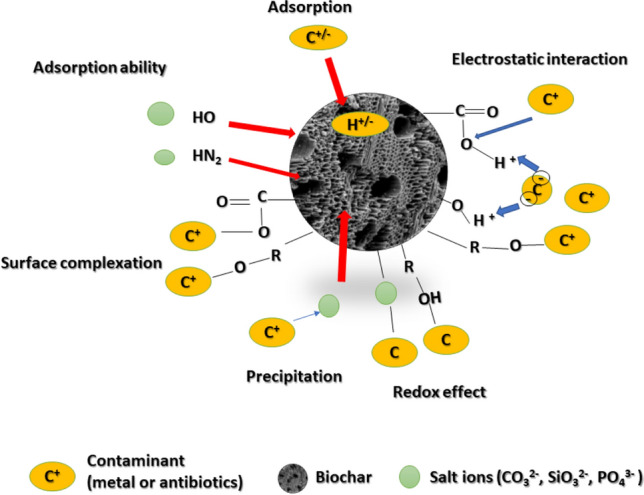

Utilisation of biochar as a litter amendment