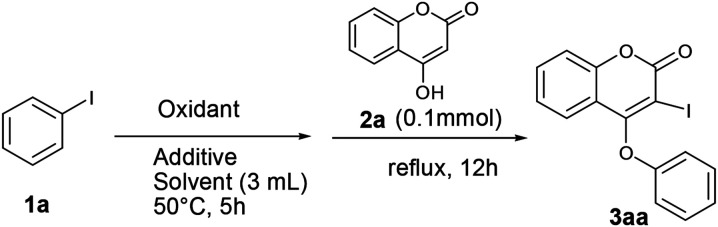

Optimization of reaction conditiona.

| |||||

|---|---|---|---|---|---|

| Entry | Oxidant (equiv.) | PhI (equiv.) | Additive (3 equiv.) | Solvent | % yieldb |

| 1 | Oxone (3) | 3 | — | 1,4-Dioxane | n.d. |

| 2 | NaIO4 (3) | 3 | — | 1,4-Dioxane | n.d. |

| 3 | K2S2O8 (3) | 3 | — | 1,4-Dioxane | n.d. |

| 4 | TBHP (3) | 3 | — | 1,4-Dioxane | n.d. |

| 5 | NaBO3·H2O (3) | 3 | — | 1,4-Dioxane | n.d. |

| 6 | mCPBA (3) | 3 | — | 1,4-Dioxane | 38 |

| 7 | mCPBA (3) | 3 | — | Toluene | 45 |

| 8 | mCPBA (3) | 3 | AcOH | 1,4-Dioxane | 50 |

| 9 | mCPBA (3) | 3 | AcOH | Toluene | 70 |

| 10 | mCPBA (3) | 3 | TsOH | Toluene | n.r. |

| 11 | mCPBA (3) | 3 | TFA | Toluene | 60 |

| 12 | mCPBA (3) | 3 | K2CO3 | Toluene | n.r. |

| 13 | mCPBA (3) | 3 | PivOH | Toluene | 90 |

| 14 | mCPBA (3) | 3 | PivOH | CH3CN | 16 |

| 15 | mCPBA (3) | 3 | PivOH | MeOH | 37 |

| 16 | mCPBA (3) | 3 | PivOH | DCE | 48 |

| 17 | mCPBA (3) | 3 | PivOH | DMF | n.d. |

| 18 | mCPBA (3) | 3 | PivOH | DMSO | n.d. |

| 19 | mCPBA (1) | 1 | PivOH | Toluene | 45 |

| 20 | mCPBA (1.5) | 1.5 | PivOH | Toluene | 68 |

| 21 | mCPBA (2) | 1.5 | PivOH | Toluene | 88 |

| 22 | mCPBA (2) | 1.5 | AcOH | Toluene | 70 |

Reaction conditions: a mixture of oxidant and iodobenzene was heated at 50 °C for 5 h in a sealed tube. Then, 2a was added and the reaction mixture was refluxed.

GC yield.