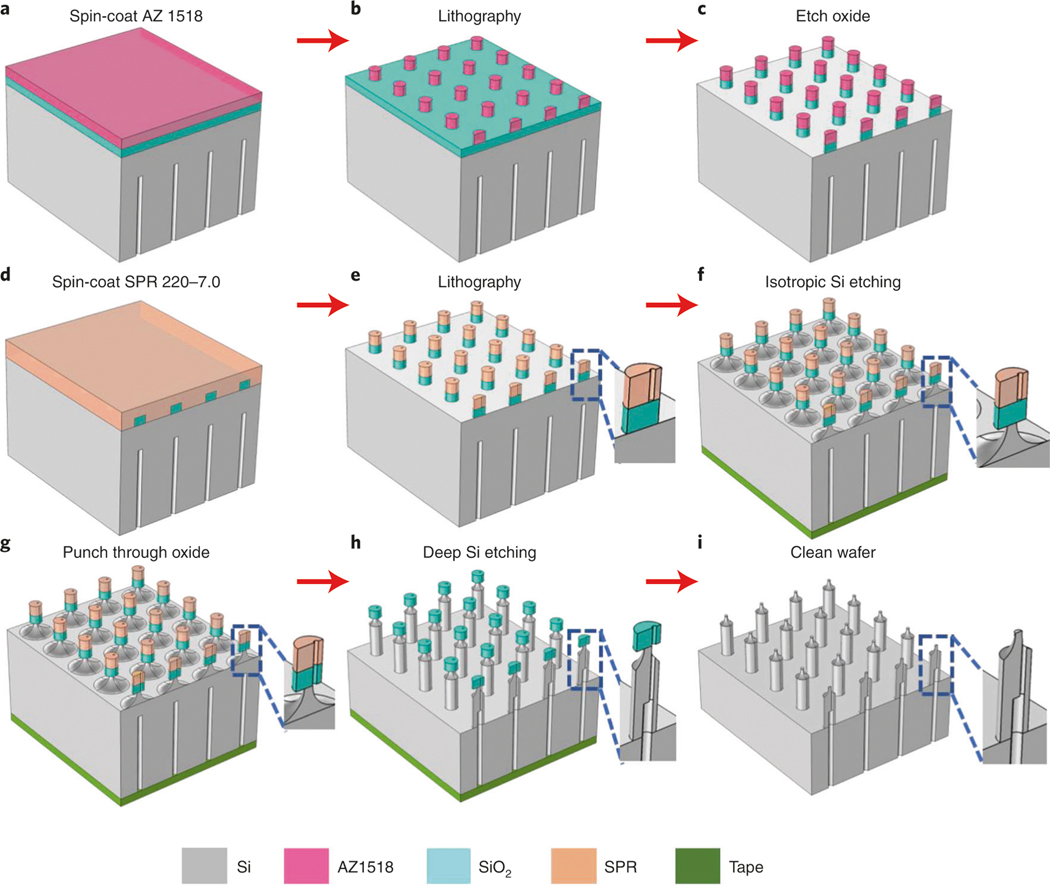

Fig. 9 |. Schematics of the fabrication process for the hollow-needle array with sharp tip and off-center bore (Type III).

a, Spin-coat AZ 1518 photoresist on the front side of the Si wafer with PECVD SiO2 deposition. b, Expose the layout (Fig. 3e) using the maskless aligner followed by development. c, Etch away the SiO2 layer in the patterned area. d, Remove the residual AZ 1518 and spin-coat SPR 220-7.0 photoresist. e, Pattern the disk arrays with an off-centered hole (Fig. 3f). f, Cover the backside holes using polyimide tape and carry out isotropic Si etching to obtain sharp tips. g, Etch through the SiO2 layer to open the off-centered holes. h, Form the off-centered hollow-needle array using the Bosch process. i, Remove the residual photoresist and oxide, followed by cleaning the wafer. See Step 1C(i–ii) for details of all the processes.