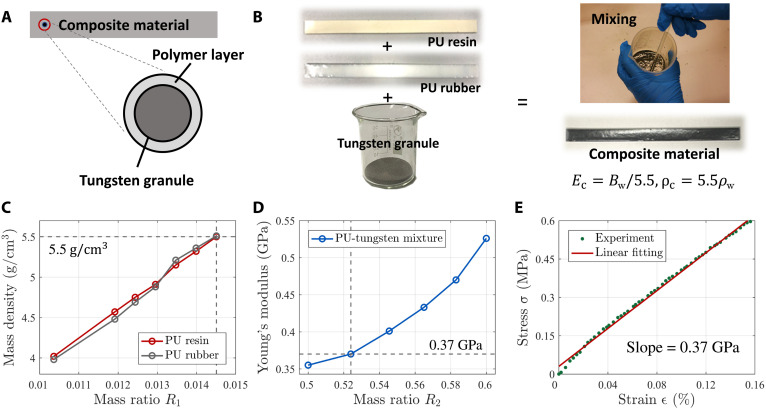

Fig. 2. The composite fabrication process for targeting α=5.5 and its verification.

(A) Schematic illustration of the composite material’s microstructure, comprising tungsten granules embedded in a polymer matrix. (B) By mixing PU resin, PU rubber, and tungsten granules, we fabricate the composite material with the targeted properties, whose final stripe shape is used for the tensile test. (C) Relation between the mass density and the mass ratio R1 = MPU/MW, for which MPU can be contributed by either varying PU resin (red) or PU rubber (gray). (D) By fixing the mass ratio R1, we change the mass ratio R2 between the PU resin and PU rubber (i.e., R2 = Mresin/Mrubber) to manipulate sample’s Young’s modulus. (E) Measured strain-stress curve for the final composite sample, showing its Young’s modulus E ≅ 0.37 × 109 Pa, the target longitudinal modulus of the rod.