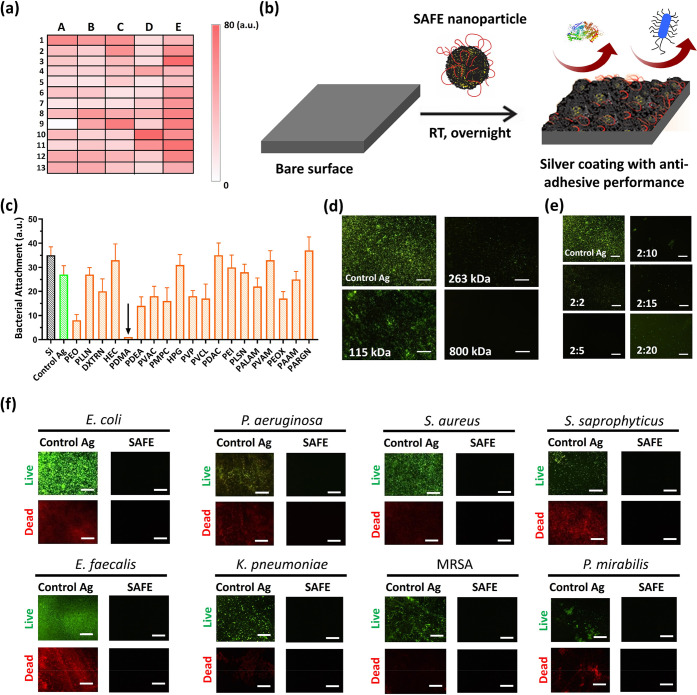

Figure 1.

High-throughput screening and identification of SAFE composition. (a) Heat map of the high-throughput screening results from the bacterial adhesion assay (E. coli, initial concentration of 1 × 106 CFU/mL in LB, 24 h) (see also Table S1 for coating compositions corresponding to the heat map units). The color intensity indicates the bacterial load attached to the surface (white, no bacteria; intense red, high bacterial load). (b) Cartoon showing the synthesis of the SAFE coating with antiadhesive performance via a one-step dip-coating protocol at room temperature. (c) Relative bacterial attachment to the surface of coatings based on different UAPs incubated with E. coli (initial concentration of 1 × 106 CFU/mL in LB) for 7 days. The black downward arrow is used to highlight the excellent bacterial adhesion prevention of the PDMA-containing coating. (d) Fluorescence images of biofilm formation by E. coli (initial concentration of 1 × 106 CFU/mL in LB, 7 days) on the surface of coatings formed on the basis of different molecular weights of PDMA. (e) Fluorescence images of biofilm formation by E. coli (initial concentration of 1 × 106 CFU/mL in LB, 7 days) on the surface of coatings formed on the basis of different DA:PDMA mass ratios. (f) Fluorescence images (green, live bacteria; red, dead bacteria) showing biofilm formation on the surface of the “control Ag” coating and the SAFE coating after 4 weeks of coincubation with diverse bacterial strains (initail concentration: 1 × 106 CFU/mL). The scale bar is 100 μm.