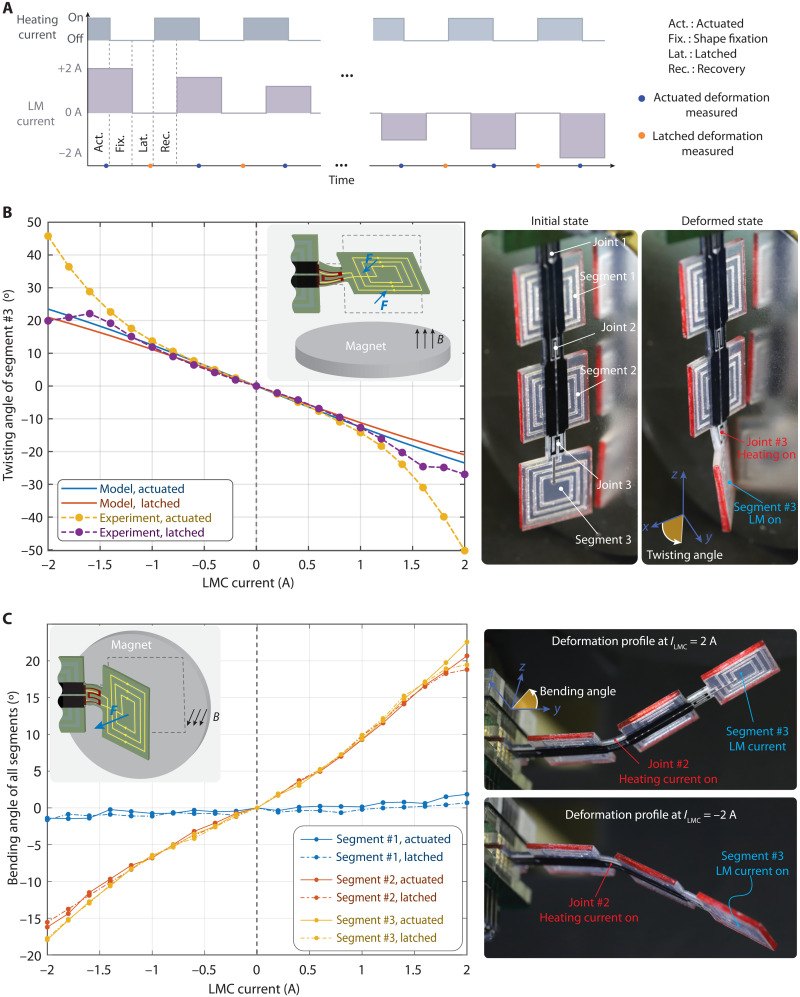

Fig. 2. Characterization of twisting and bending deformation and latching.

(A) Time sequence of the voltage applied to the heaters and of the current driven in the LM coils (LM current). For each LM current, the device is actuated, the shape is then fixed, and, lastly, the initial flat shape is recovered by heating the joint. (B) Measured and simulated twisting angle of the third joint versus LM current in the third segment, heating only the third joint. The initial and deformed states of the beam are shown on the right-hand side of the panel. The relative position of the magnet and segment is shown in the inset. The model predictions and the experimental data are in very good agreement for the LM current up to 1.5A. Above this current, heat from current in the LM coil softens the joint even when no heating voltage is applied. (C) Measured actuated and latched bending angles of all three segments, with heating applied only to the second joint and LM current only in the third segment. Because the joints between the holder and the first segments and between the second and third segments remain stiff during this test, segment 1 does not move, and segments 2 and 3 have the same bending angle.