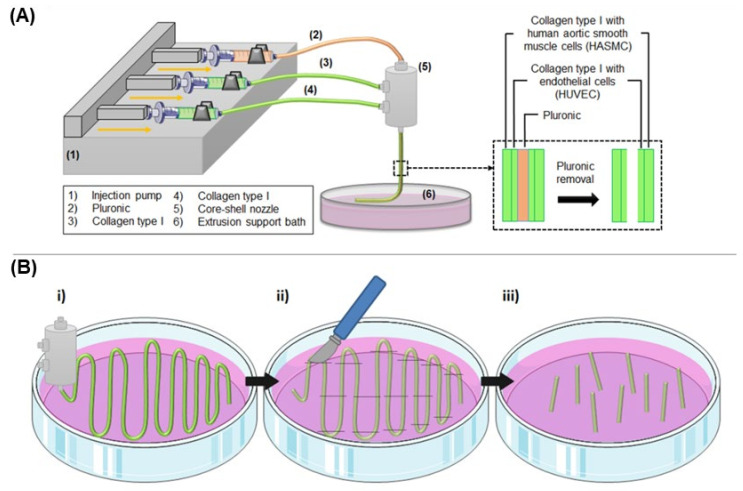

Figure 4.

Schematic representation of collagen TEBV development through the triple concentric extrusion method. (A) Pluronic (2) and collagen type I (3 and 4) are injected into a triple concentric nozzle (5) in the inner, middle and outer layer, respectively. These biomaterials are extruded in a constant injection speed controlled by an injection pump (1) into a petri dish containing an extrusion support bath or support-free bath (6). Independently of the extrusion support bath, the fibers are extruded at room temperature (approximately 20 °C) for around 5–10 min, followed by incubation at 37 °C for 10–15 min to allow collagen gelation. Then, Pluronic is removed from the inner core by dissolution with cell culture media, obtaining a hollowed dual layer tubular structure. (B) (i) Co-axial nozzle extrudes following a zig-zag pattern, and once TEBVs are gelled (ii–iii) the straight parts are cut to the desired length.